Sand core pressure-casting servo driving system of vertical parting molding machine

A vertical parting, servo-driven technology, applied in the manufacturing field, can solve the problems of high noise, difficult control, serious energy consumption, etc., and achieve the effect of less hydraulic valve block components, convenient maintenance and noise reduction.

Inactive Publication Date: 2013-03-13

青岛双星铸造机械有限公司

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The sand core die-casting control system of the molding machine is generally controlled by a conventional motor, and is controlled by 6 valve bodies. The displacement measurement uses a rotary encoder. This control method is very noisy, and it is difficult to control the 6 valve bodies separately. Once a fault occurs, it is difficult to find the cause and maintain it. At the same time, the displacement accuracy of the positive and negative pressure plates is not high, which delays production and affects production efficiency; inconvenient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

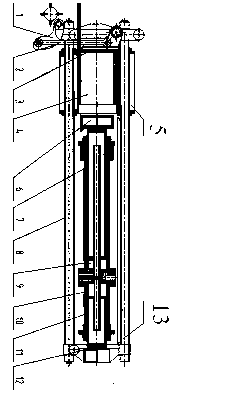

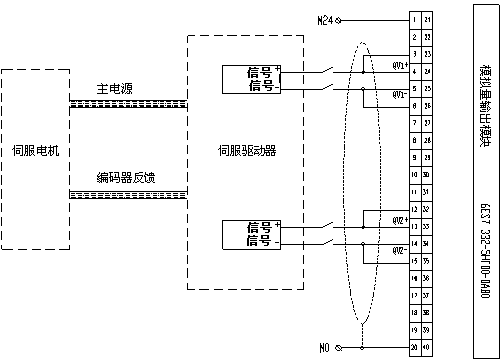

The invention relates to a sand core pressure-casting servo driving system of a vertical parting molding machine. The servo driving system comprises a control mechanism, a profiling chamber and a servo motor. A front driving module and a rear driving module are arranged in the control mechanism. The front driving module comprises a front oil cylinder, a forward pressing plate and a front oil cylinder piston, wherein the forward pressing plate is arranged at the front part of the profiling chamber and connected with the front oil cylinder. The rear driving module comprises a backward pressing plate, a rear oil cylinder, a guide rod and a cam mechanism, wherein the backward pressing plate is arranged at the rear part of the profiling chamber; the rear oil cylinder is fixed at the rear part of the front oil cylinder; the rear oil cylinder is connected with the guide rod through a standing base behind the rear oil cylinder; the guide rod is connected together with the cam mechanism through a guide sleeve; and the cam mechanism is connected together with the backward pressing plate through a connecting rod mechanism.

Description

Technical field [0001] The invention belongs to the field of manufacturing technology, and specifically relates to a vertical parting molding machine sand core die casting servo drive system. Background technique [0002] The sand core die-casting control system of the moulding machine is generally controlled by a conventional ordinary motor, and is controlled by 6 valve bodies. The displacement measurement uses a rotary encoder. This control method is particularly noisy, and it is difficult to control the 6 valve bodies separately. Once a failure occurs, it is difficult to find the cause and repair. At the same time, the displacement accuracy of the positive and negative pressure plates is not high, which delays production and affects production efficiency; and the plunger pump of the equipment is always in working condition and consumes serious energy; the hydraulic valve block is complicated and maintenance inconvenient. Summary of the invention The invention overcomes the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22C9/10B22D17/32

Inventor 沙克清李长太王海军张子斌张春玲

Owner 青岛双星铸造机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com