Processing technology of composite nonwoven fabric

A processing technology, non-woven technology, applied in the field of composite non-woven processing technology, can solve the problems of difficult liquid flow, large contact area, poor dry performance, etc., to increase the absorption effect, reduce the contact area, and increase the surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

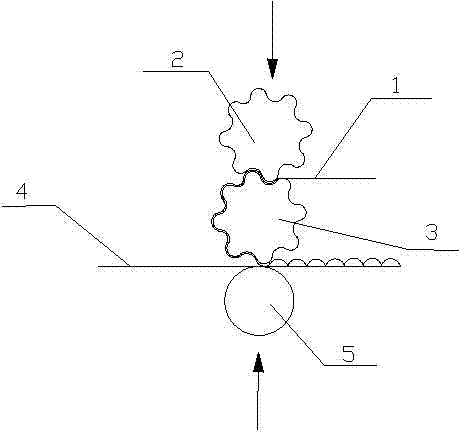

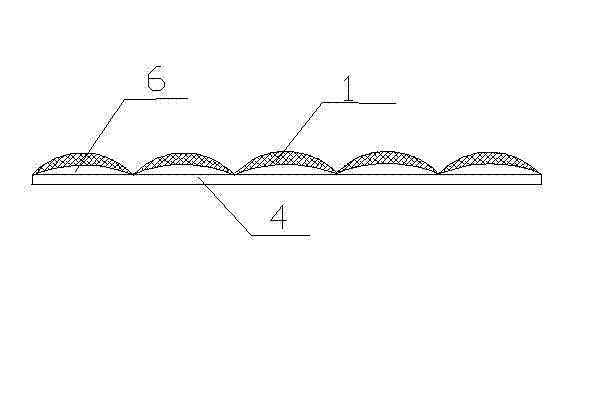

[0011] like figure 1 It is the process flow chart of the present invention, a processing technology of composite non-woven fabric, the non-woven fabric surface layer 1 is introduced between the convex roller 2 and the concave roller 3 with concave-convex patterns and the contact surfaces mesh with each other, and the convex roller 2 to pressurize, and the extruded non-woven fabric surface layer 1 with concave-convex pattern is driven by the concave roller 3 and the non-woven fabric bottom layer 4, and then passes through the contact surface of the shaping hot roll 5 and the convex point on the concave roller 3 Compound together, and carry out pressure on the sizing hot roll 5. Composite composite non-woven fabrics such as figure 2 As shown, the non-woven fabric surface layer 1 and the non-woven fabric bottom layer 4 are combined together, the non-woven fabric surface layer 1 shows a concave-convex effect, and there is a hollow layer 6 between the non-woven fabric surface lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com