Device for coating bridge underwater pile with concrete

A technology for outsourcing concrete and piles, applied in construction, infrastructure engineering, etc., can solve the problems of large amount of auxiliary works, low economic benefits, and inability to fix the device, and achieves uniform concrete thickness, convenient and flexible disassembly, and guaranteed construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

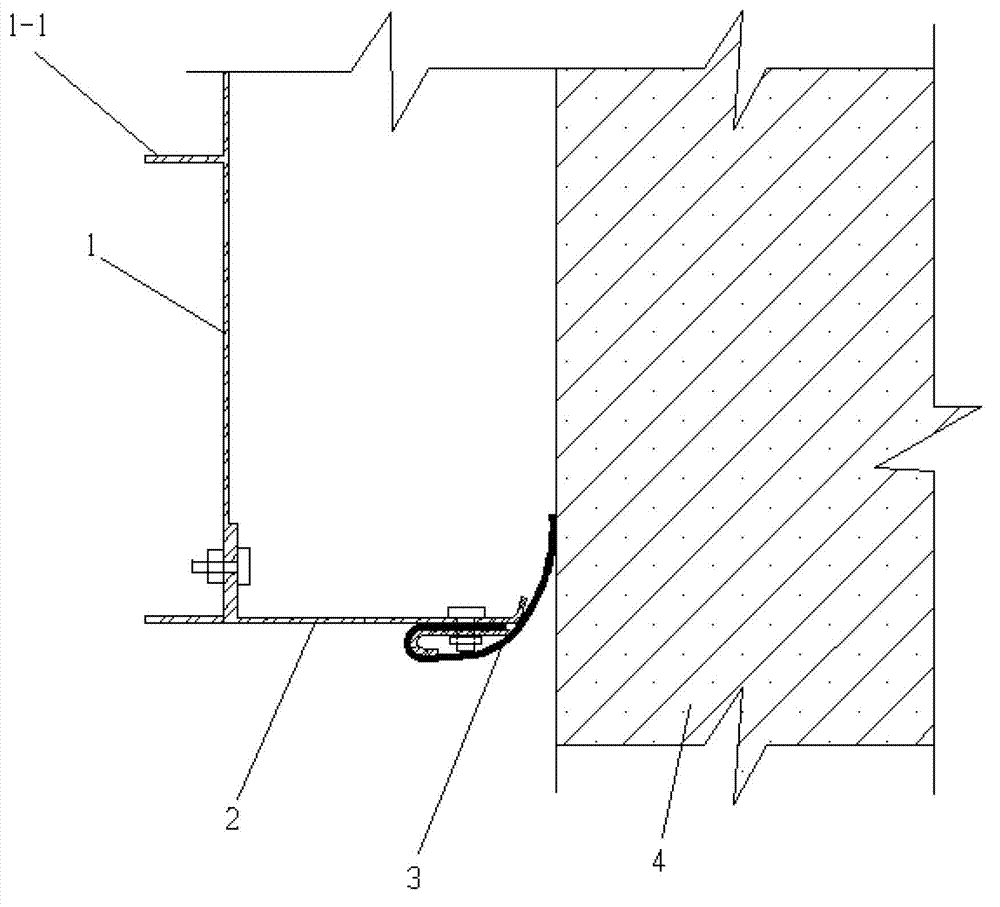

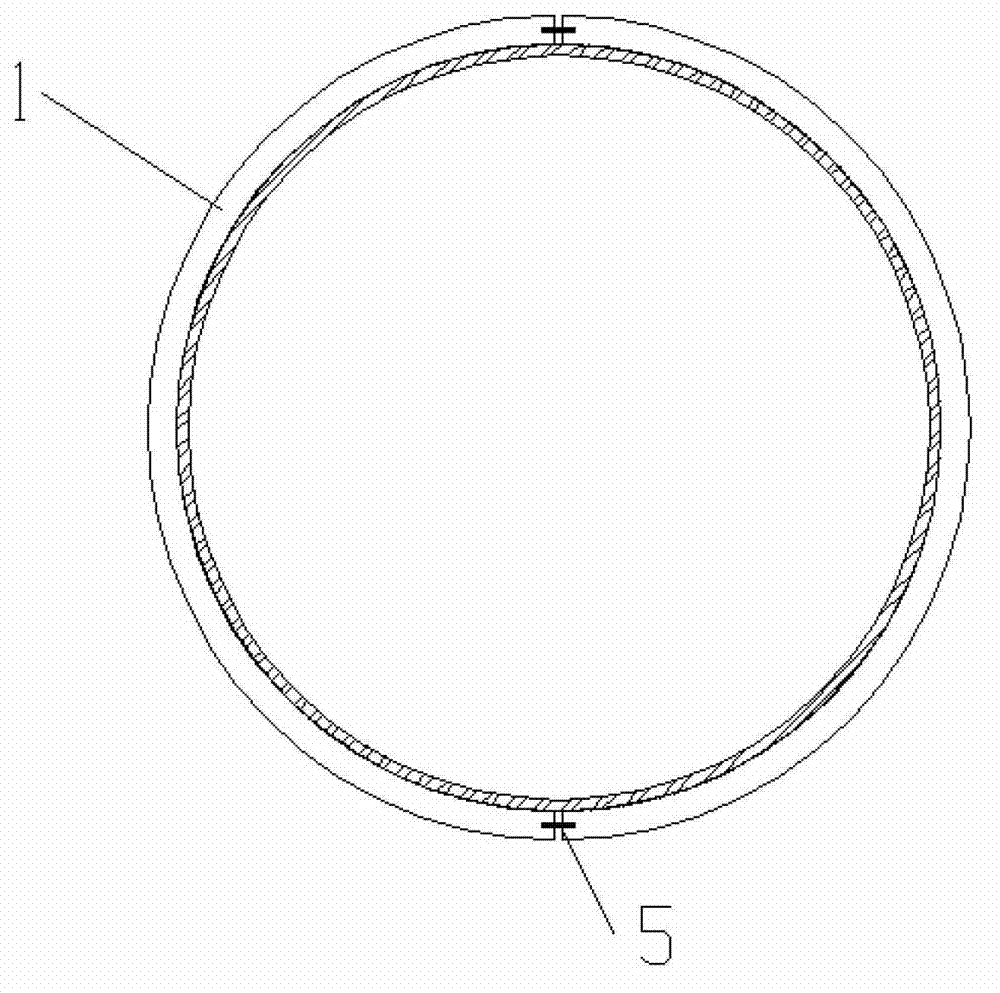

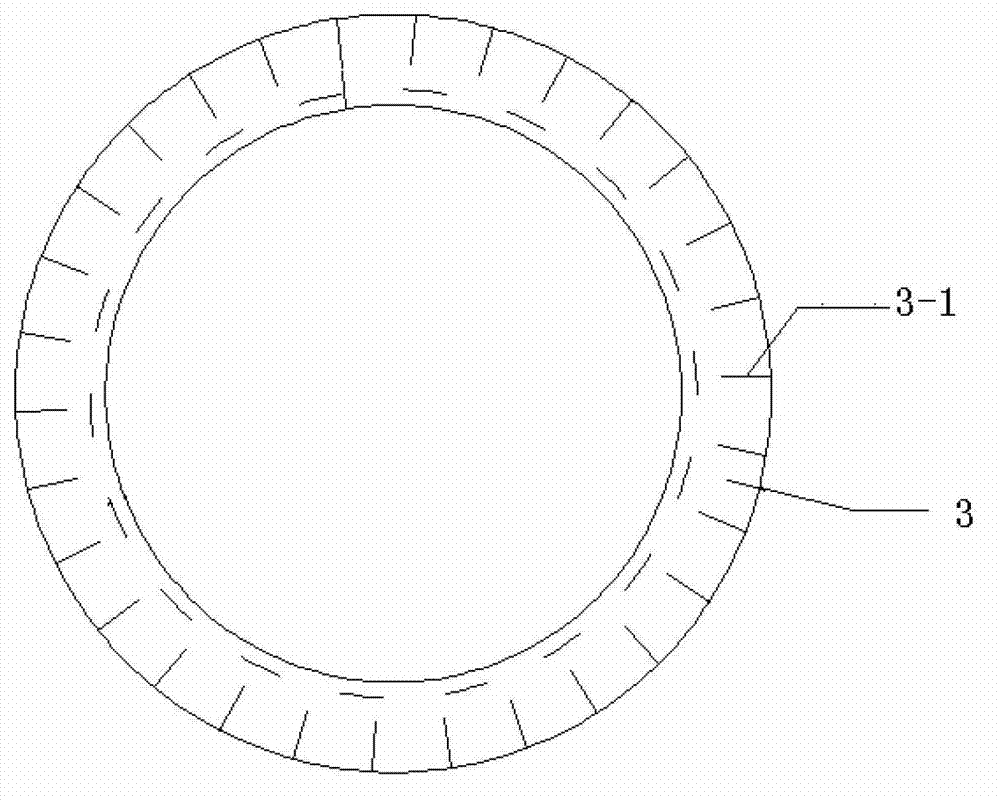

[0019] Such as figure 1 As shown, the device for outsourcing concrete for bridge underwater piles of the present invention comprises a steel sleeve 1, an annular back-sealing steel plate 2 of the steel sleeve 1, and an annular rubber valve plate 3, and the inner diameter of the steel sleeve 1 is greater than that of the pile 4. Diameter, the steel sleeve 1 is formed by connecting two semicircular steel plates with symmetrical shapes, there is a gap between the inner ring edge of the annular bottom cover steel plate 2 and the pile 4, the outer ring edge is connected with the steel sleeve 1 by bolts, and the ring The inner ring edge of the rubber valve plate 3 is fixedly connected with the inner ring edge of the annular bottom cover steel plate 2, and the outer ring edge of the annular rubber valve 3 has a slit and is turned into the steel sleeve 1 to be close to the pile 4.

[0020] The steel sleeve 1 is formed by connecting two symmetrically shaped semicircular steel plates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com