Axial flow type fluid driving device

A fluid-driven, axial-flow technology, applied to parts of pumping devices for elastic fluids, axial-flow pumps, liquid fuel engines, etc., can solve problems such as large operating noise, resonance phenomenon, and large moment of inertia, and achieve Improve the conveying efficiency and increase the effect of passing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with specific embodiment, see figure 1 -5:

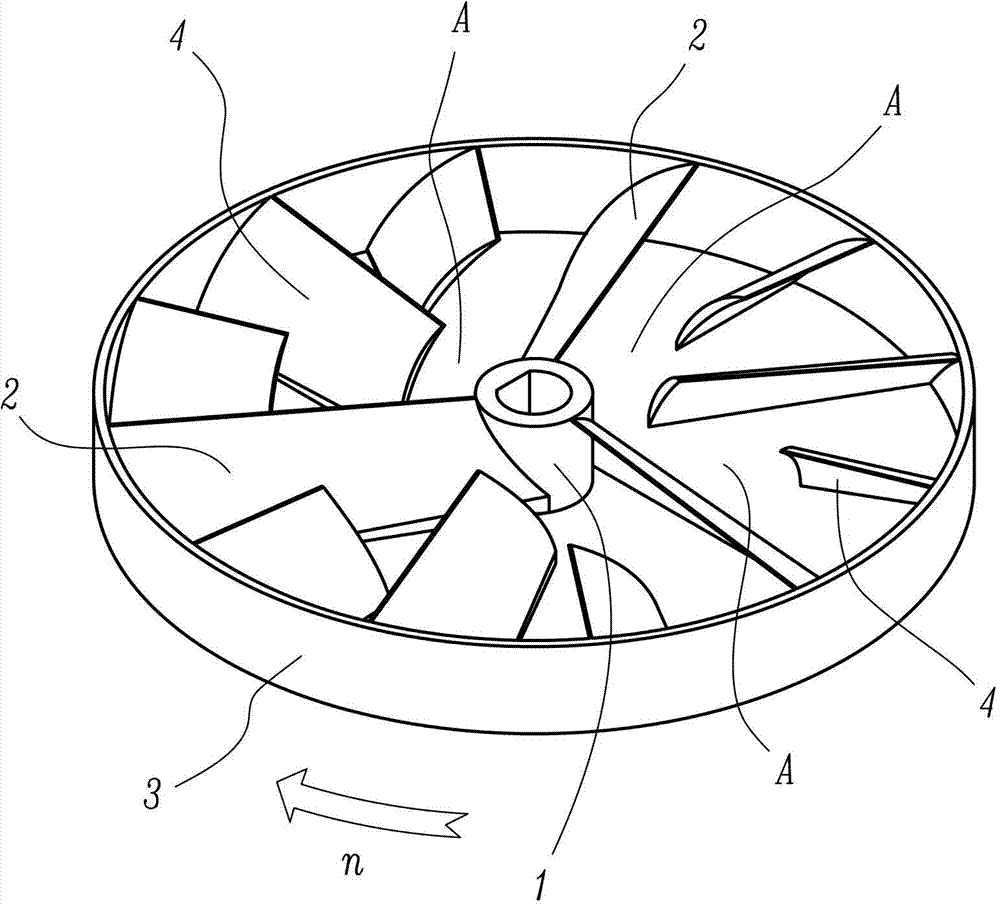

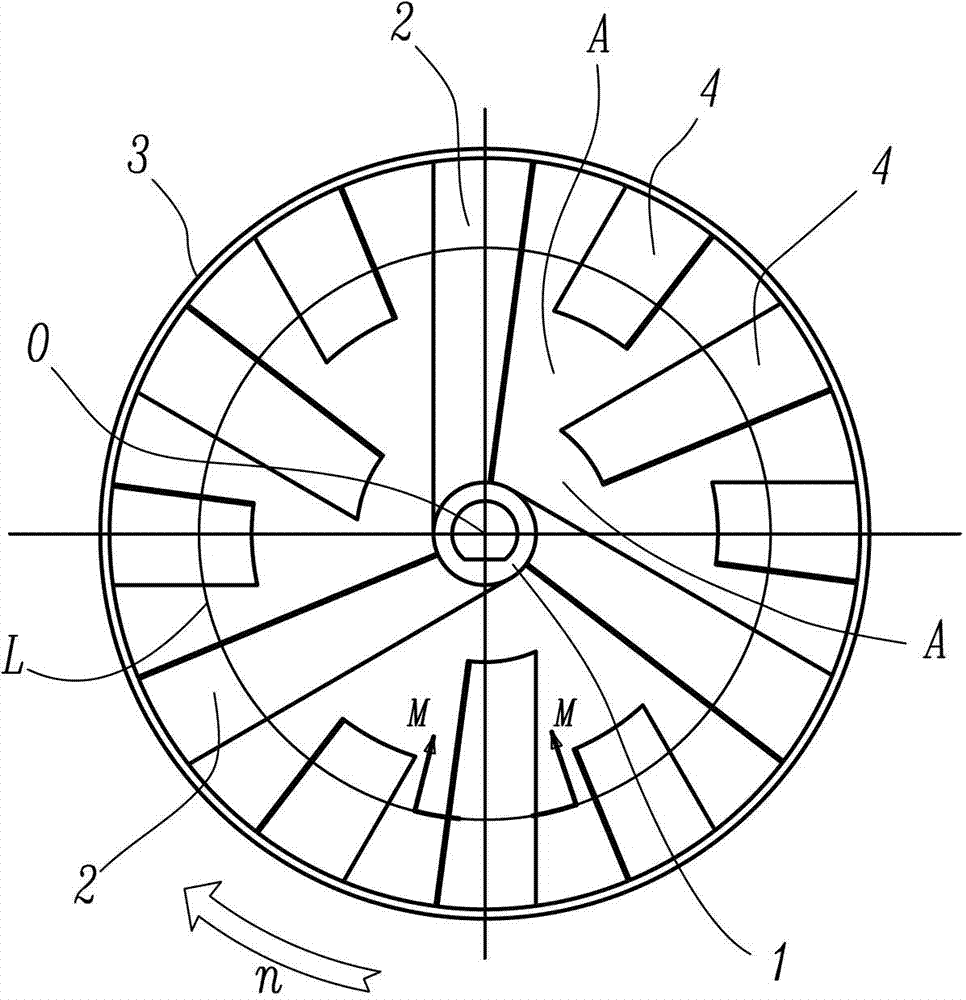

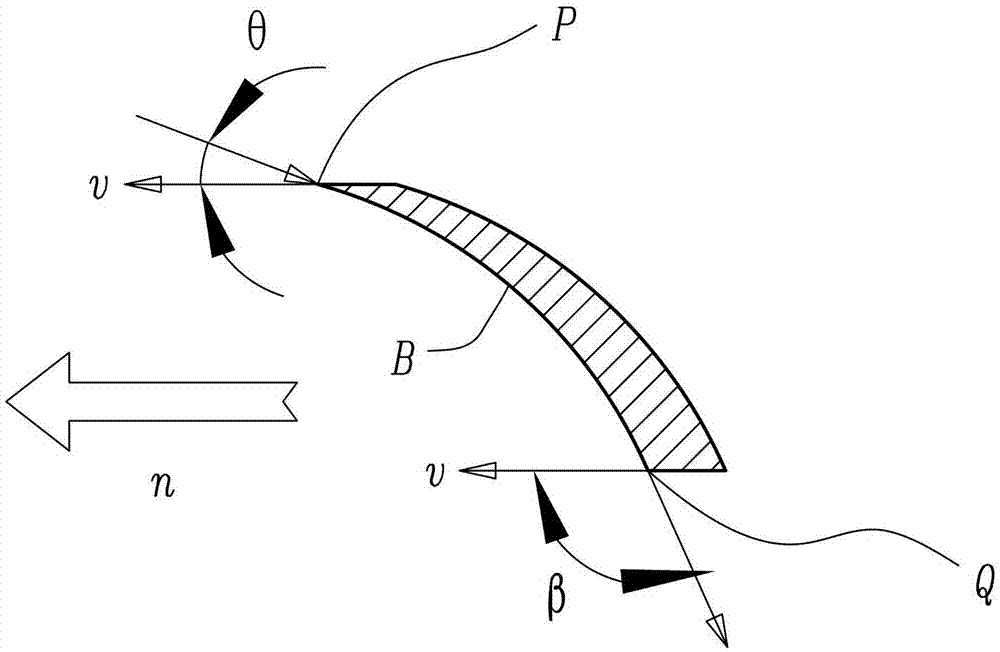

[0022] An axial fluid drive device, which includes a hub 1, fan blades 2 and a fairing 3, wherein the fan blades 2 are radially arranged between the hub 1 and the fairing 3, and the hub 1, the fan blades 2 and the fairing 3 Rotate together synchronously, the fan blade 2 is a strip-shaped blade with a certain width, and the fan blade 2 and its rotation plane present a certain inclination angle to generate an axial driving force for the fluid working medium; the characteristics of the present invention are: There are suspended blades 4, the inner end of the suspended blades 4 adopts a cantilever structure, and the outer end of the suspended blades 4 is tightly connected with the fairing 3 or made in one structure with the fairing 3; the fairing 3 can be a closed-loop structure (such as figure 1 and figure 2 shown) can also be an open-loop structure (not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com