Foil radial bearing with high heat dissipation rate, combined bearing and bearing thermal management method

A technology of high-efficiency foil type and combined bearing, applied in the direction of bearing, shaft and bearing, bearing cooling, etc., can solve the problems of reducing the maximum load capacity of foil type aerodynamics, the distortion of the top smooth foil, and the degradation of coating performance. , to enhance the heat transfer effect of convective cooling, not easy to local permanent deformation, and reduce the viscosity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

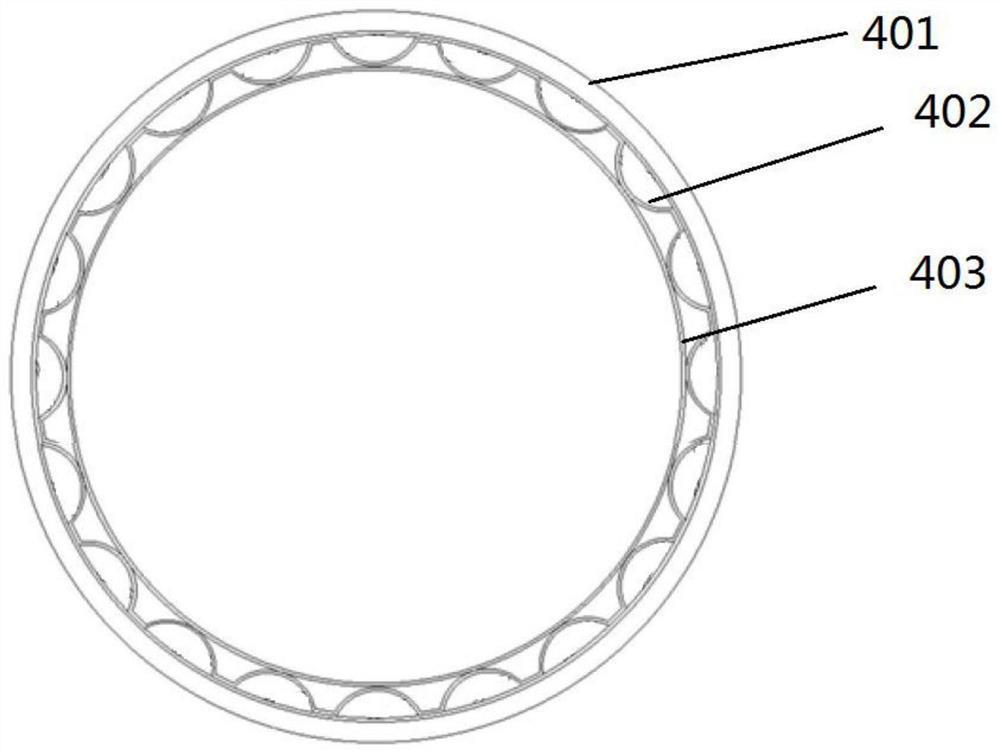

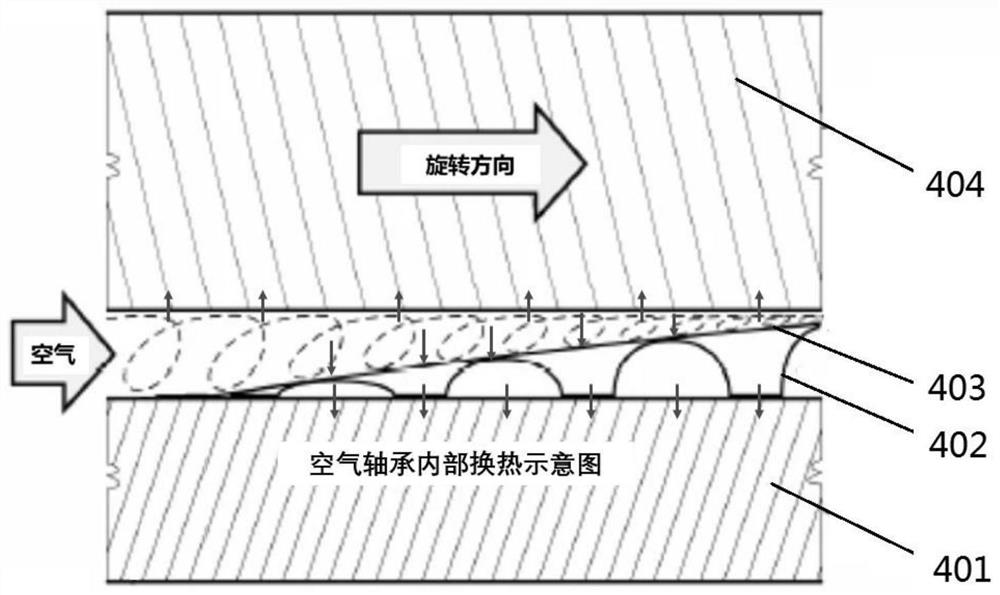

[0049] Such as Figure 4-7 As shown, a high heat dissipation rate foil type radial bearing 4 includes a bearing shell 41, a corrugated elastic foil 42 and a smooth foil 43 arranged on the inner surface of the bearing shell 41, and the smooth foil 43 The outer surface is in contact with the top of the corrugated inner convex part 421 of the corrugated elastic foil 42, and it is characterized in that, corresponding to the corrugated inner convex part 421 of the corrugated elastic foil 42, the inner surface of the bearing housing 41 is provided with There are axial cooling air slots 411 . The number and position of the axial cooling air grooves 411 correspond to the design and position of the corrugated inner convex part 421 of the corrugated elastic foil 42, which does not affect the support of the corrugated elastic foil 42 of the air foil bearing and increases The axial cooling air groove 411 can expand the area of the cooling air flow channel and increase the flow rate of ...

Embodiment 2

[0055] A high heat dissipation rate foil type composite bearing 3, such as Figure 8-12 As shown, it includes a foil type axial thrust bearing 2 and the above-mentioned high heat dissipation rate foil type radial bearing 4, the working end surface of the foil type axial thrust bearing 2 is in contact with the high heat dissipation rate foil type radial bearing The end face of one side of the bearing shell 41 of the bearing 4 is coaxially connected, or the end face of one side of the bearing shell 41 of the high heat dissipation foil type radial bearing 4 extends outward to form the work of the foil type axial thrust bearing End face 21. Because the combination bearing 3 has the cooling air groove 411 of the foil type radial bearing 4 with a high heat dissipation rate, it can reduce the temperature rise of the rotating shaft, smooth foil and corrugated elastic foil due to the aerodynamic heat of the gas film, and can also reduce the temperature of the rotating shaft. , Axial t...

Embodiment 3

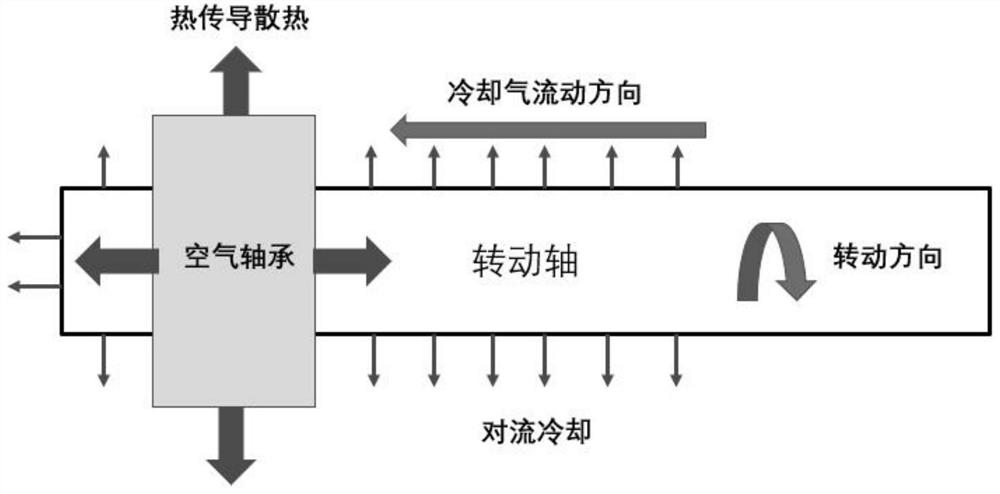

[0062] A heat management method for high heat dissipation rate foil bearings, comprising the above-mentioned high heat dissipation rate foil type radial bearing 4 and high heat dissipation rate foil type The combined bearing 3 is assembled between the rotor 5 and the motor casing 1, and its application in the air compressor for fuel cells is as Figure 13 As shown, the end of the rotor 5 close to the impeller 7 and the volute 8 is provided with a thrust plate 51 .

[0063]On the right side of the thrust plate 51 (the side where the impeller 7 and the volute 8 are located) assemble a foil shaft with the same structure as the working end surface of the foil axial thrust bearing of the high heat dissipation rate foil composite bearing 3 To the thrust bearing 2, the high heat dissipation rate foil type combined bearing 3 is assembled on the left side of the thrust plate 51, and the working end faces of the foil type axial thrust bearings all face the thrust plate 51 layout. Fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com