High-heat-dissipation-rate foil type axial thrust bearing, combined bearing and heat management method

A high-speed foil type and thrust bearing technology, applied in the direction of shafts and bearings, bearings, bearing components, etc., can solve the problem of reducing the maximum load capacity of foil type aerodynamics, the incomplete formation of air film 405, and the small amount of cooling air, etc. problem, to achieve enhanced convective cooling heat transfer effect, enhanced cooling heat transfer effect, and increased cooling gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

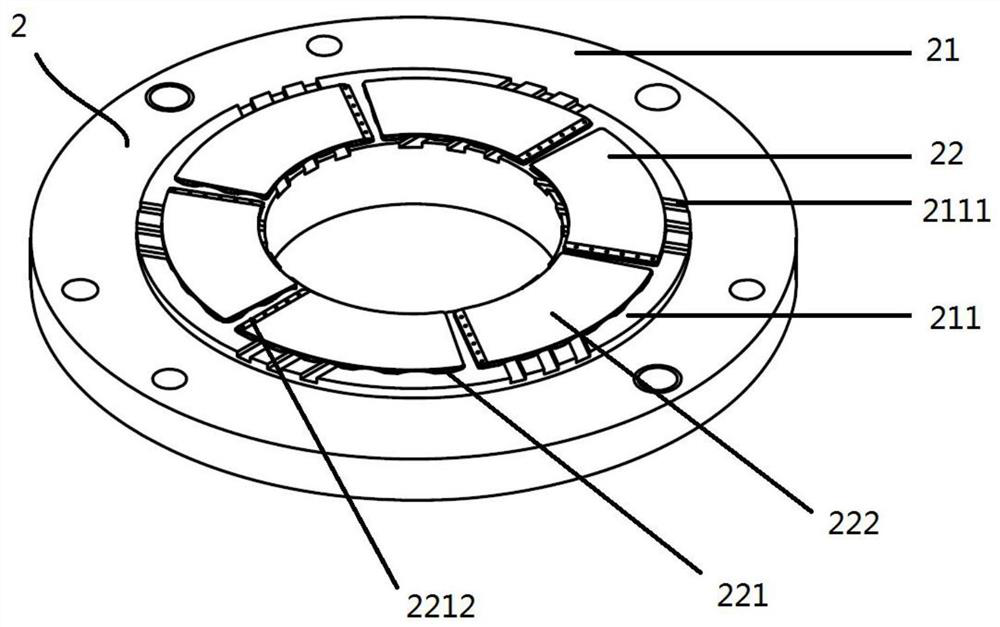

[0053] Such as Figure 3-8 As shown, a foil-type axial thrust bearing 2 with high heat dissipation rate includes a base body 21 and six fan-shaped annular foil groups 22. The end face of the base body 21 is coaxially provided with an annular boss 211, and the six said The fan ring foil groups 22 are arranged on the end surface of the ring boss 211 symmetrically and non-overlappingly to the center of the circumference; and there are radial gaps between the side edges of adjacent fan ring foil groups. Each of the fan-shaped ring-shaped foil sets 22 includes a smooth foil 222 and a corrugated elastic foil 221, and the corrugated elastic foil 221 and the smooth foil 222 are both fan-shaped and stacked in sequence and welded to the ring. The upper surface of the boss 211, that is, the corrugated elastic foil 221 is interposed between the boss 211 and the smooth foil 222; and corresponds to the corrugated upper convex portion 2211 of the corrugated elastic foil 221, The upper surfa...

Embodiment 2

[0058] A high heat dissipation rate foil type composite bearing 3, such as Figure 9-13 As shown, it includes a high heat dissipation rate foil type radial bearing 4 and the above-mentioned high heat dissipation rate foil type axial thrust bearing 2, and the non-working end surface of the high heat dissipation rate foil type axial thrust bearing 2 (without One side of the fan ring foil group 22 is fixed) and the end surface of the bearing shell 41 side of the high heat dissipation rate foil radial bearing 4 is coaxially connected, or the high heat dissipation rate foil type axial thrust The non-working end face side of the bearing 2 extends outward in the axial direction to form a bearing shell 41 of the foil radial bearing 4 .

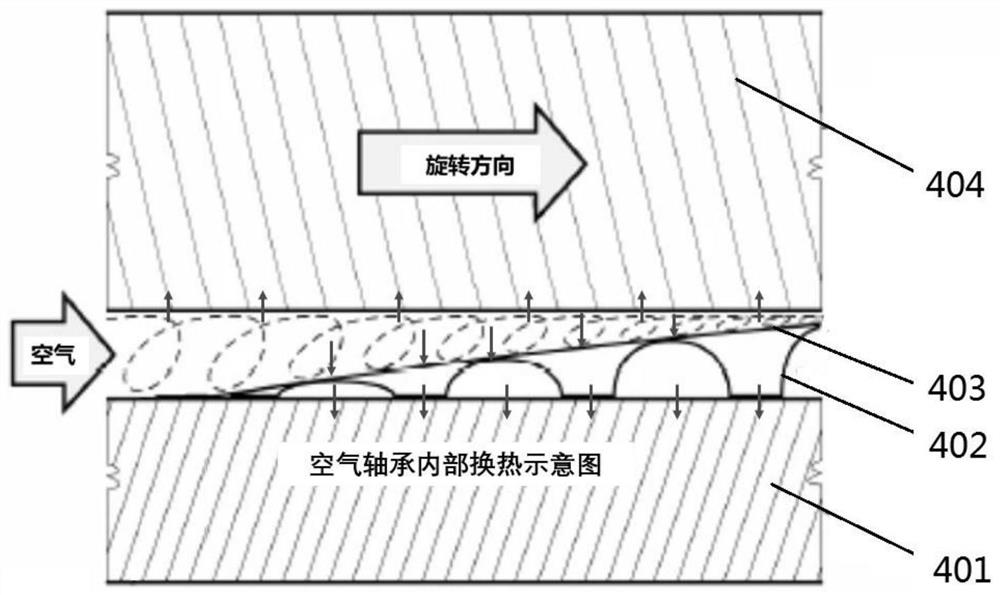

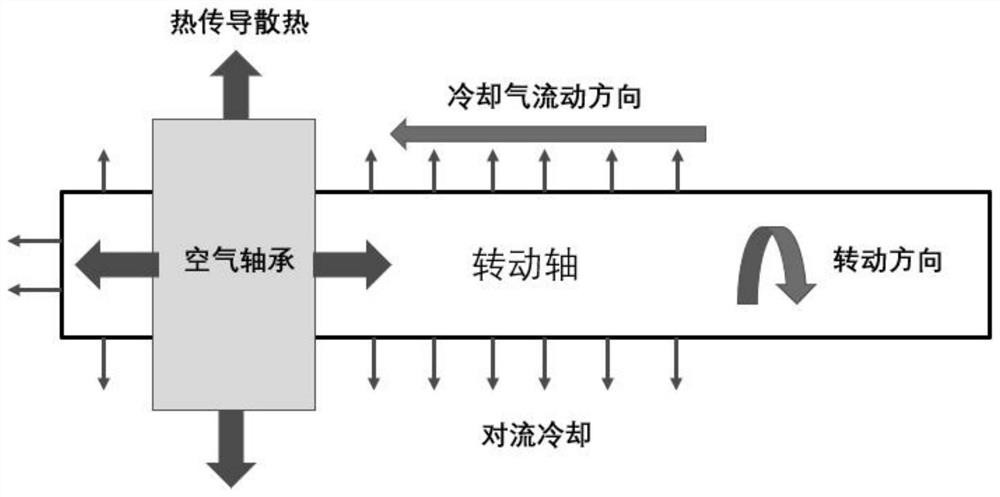

[0059] As a preference, the inner surface of the high heat dissipation foil radial bearing 4 is coaxial and is provided with an axial corrugated elastic foil 42 and an axial smooth foil 43 sequentially along its radial direction, and the axial smooth ...

Embodiment 3

[0065]In the fuel cell air compressor, micro gas turbine, or oil-free fan, the above-mentioned high heat dissipation rate foil type axial thrust bearing 4 and high heat dissipation rate foil type combined bearing 3 are assembled to the rotor 5 and the motor casing Between body 1, the application in air compressors for fuel cells such as Figure 14 As shown, the end of the rotor 5 close to the impeller 7 and the volute 8 is provided with a thrust plate 51 .

[0066] On the right side of the thrust plate 51 (the side where the impeller 7 and the volute 8 are located) assemble a described high heat dissipation rate foil type axial thrust bearing 2, and assemble the high heat dissipation on the left side of the thrust plate 51 Foil type combined bearing 3 with high heat dissipation rate, and the working end faces of the high heat dissipation rate foil type axial thrust bearing and the high heat dissipation rate foil type combined bearing 3 are arranged facing the thrust plate 51 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com