An electromagnetic ultrasonic transducer for automatic detection of steel bar surface

An automatic detection and electromagnetic ultrasonic technology, which is applied in the direction of ultrasonic/sonic/infrasonic generation, can solve the problems of slow detection speed of magnetic particle inspection, poor detection sensitivity of sub-surface defects, and inability to meet the needs of inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

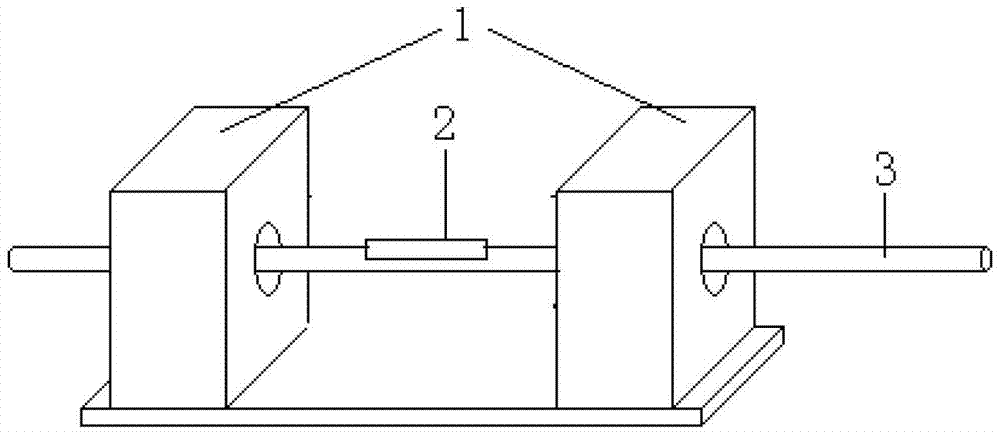

[0025] Figure 1 ~ Figure 4 It is a specific embodiment of the present invention.

[0026] The electromagnetic ultrasonic transducer of the present invention includes a detection coil, a magnetization device and a workpiece to be inspected. like figure 1 shown.

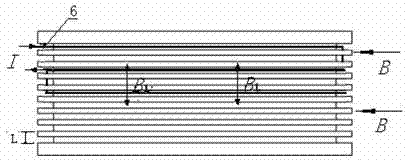

[0027] The magnetizing device 1 among the present invention is made up of two groups of completely identical coils and casing, as figure 2 shown. The coil 4 is made of enameled wire, and the two sets of coils are connected in series. When a direct current is passed through it, an axially distributed stable magnetic field B can be generated in the rod to be detected. The shell 5 of the magnetizing device is made of ferromagnetic material, so that the magnetic field generated by the coil 4 is limited in the magnetic circuit formed by the shell of the magnetizing device and the bar to be detected, so that the bar can be magnetized to the greatest extent.

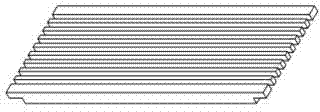

[0028] The detection coil 2 in the present invention is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com