Thin broadband sound-absorbing structure of composite multi-layer mechanical impedance plates

A technology of mechanical impedance and porous sound absorption, which can be used in sound-producing instruments, layered products, and layered products of hydraulic materials, etc., and can solve the problems of poor low-frequency sound absorption performance and narrow sound absorption frequency band.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

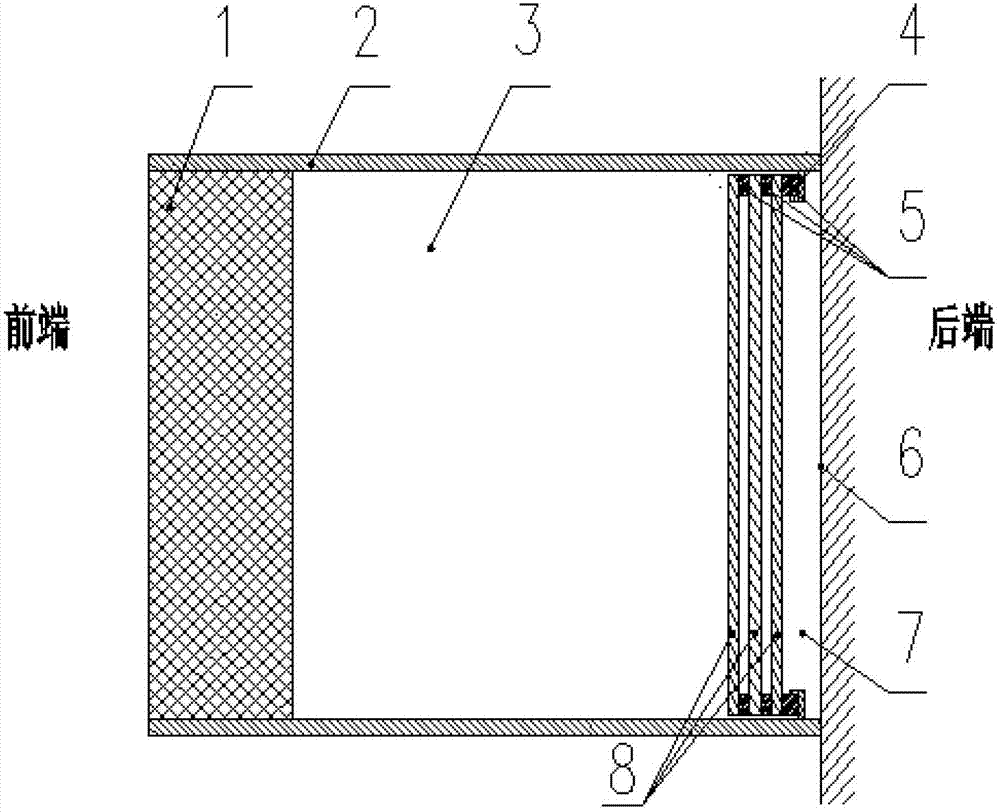

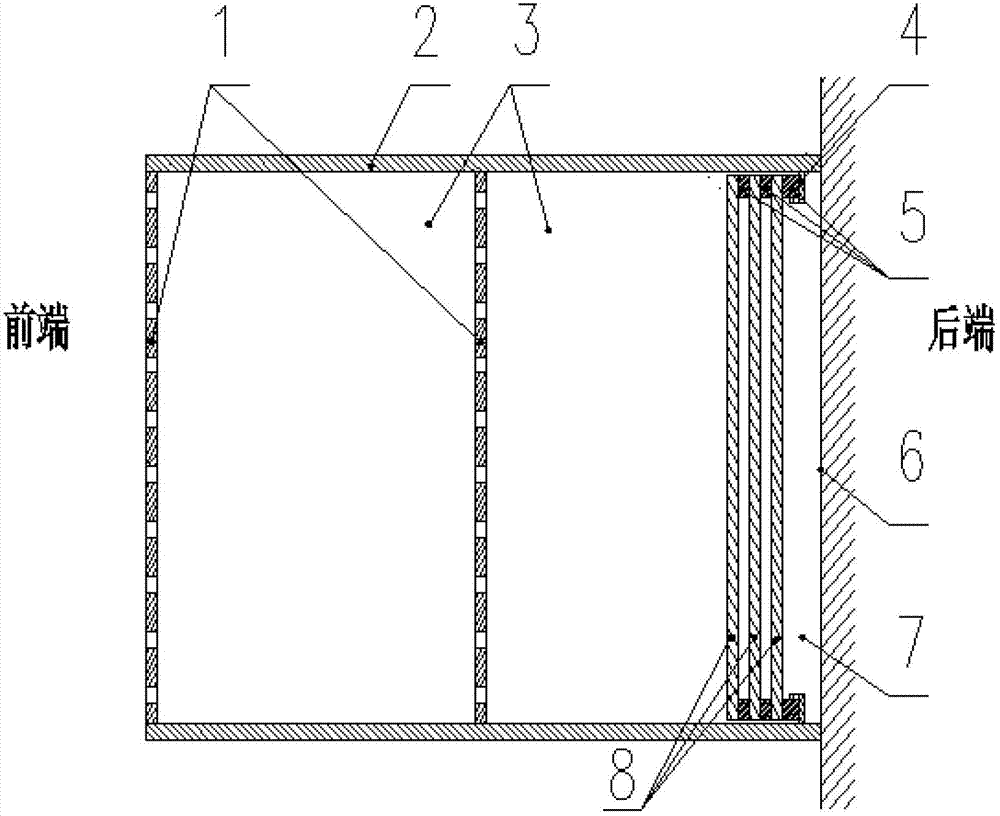

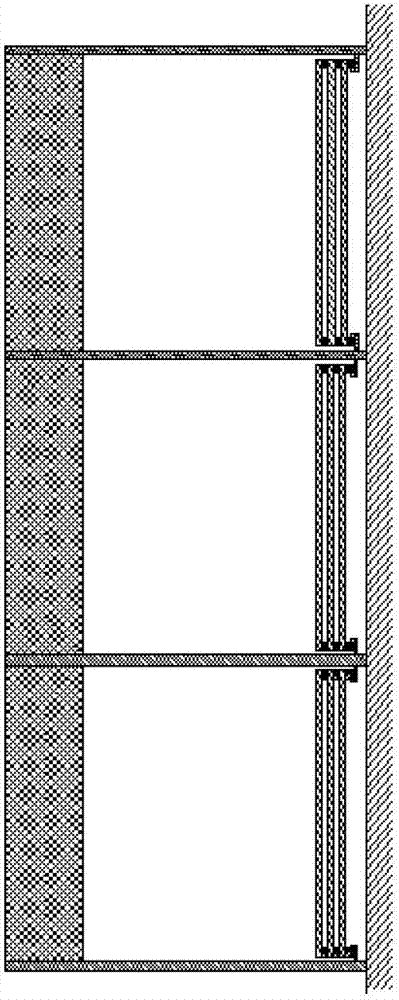

[0013] attached figure 1 It is the basic structure diagram of the present invention, among the figure 1. sound-absorbing material, can be glass wool, slag wool, rock wool, foamed plastics, asbestos fleece, felt etc., 2. bracket, 3. cavity, 4. pallet, 5. Viscoelastic ring, 6. Wall, 7. Cavity, 8 Backplate. Such as figure 1 As shown, the invented sound-absorbing structure is composed of bracket 2, sound-absorbing material (structure) 1 and multi-layer mechanical impedance plate, wherein the mechanical impedance plate is composed of back plate 8 and viscoelastic ring 5. The sound-absorbing material (structure) is installed on the inside of the front end of the support 2, wherein the surface of the porous sound-absorbing material can be laid with fabrics, perforated cover panels, films, cover nets and decorative wooden strips, etc. that do not affect the sound-absorbing performance of the sound-absorbing material. Armor. The mechanical impedance plate is installed on the inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| damping factor | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com