Starting method of modular multi-level flexible direct-current transmission converter

A flexible DC power transmission, modular multi-level technology, applied in output power conversion devices, electrical components, etc., can solve the problem of intensifying the internal dependence of valve control system hardware, high control system resource consumption, and poor operability, etc. problems, to achieve the effect of simplifying the starting method, reducing requirements, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further introduced below.

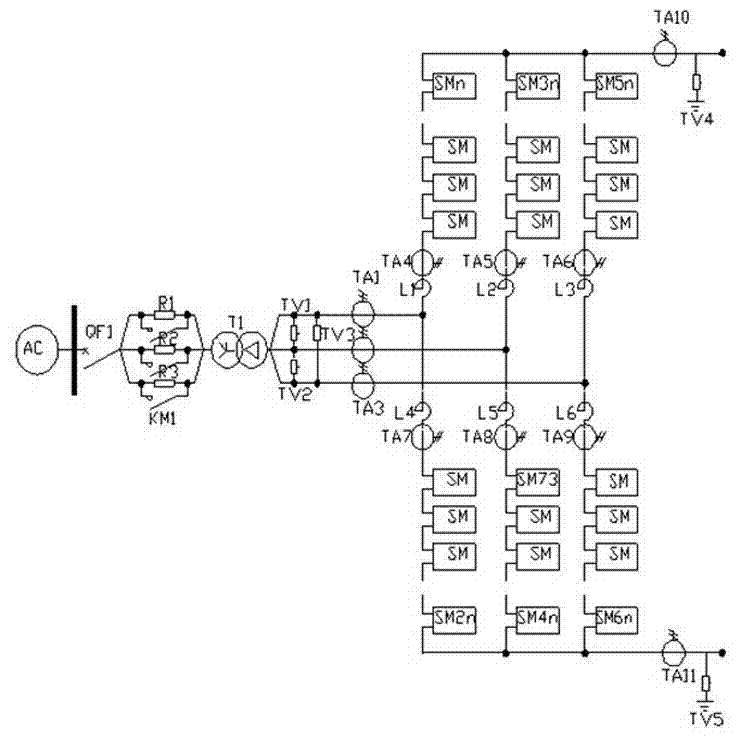

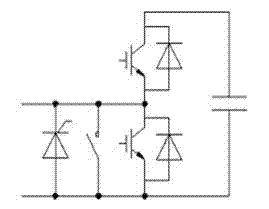

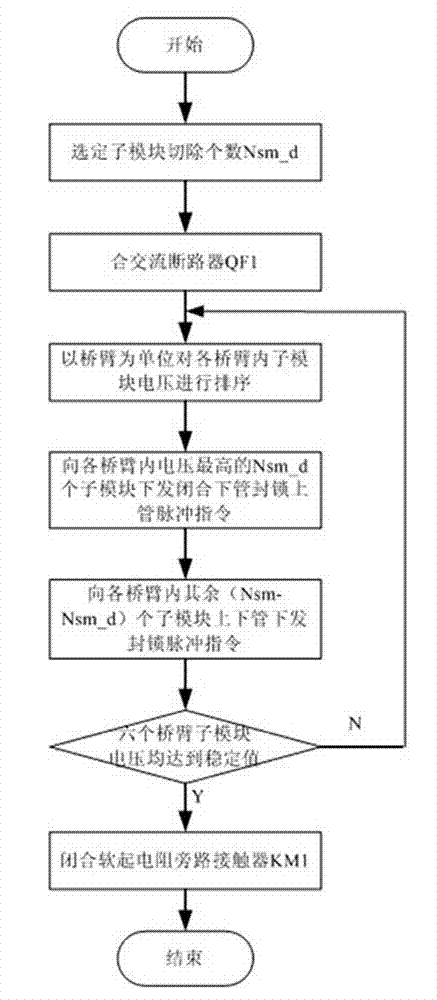

[0026] The basic topology of the modular multilevel flexible HVDC converter is as follows: figure 1 as shown, figure 2 It is a schematic diagram of the sub-module structure. The modular multi-level flexible DC transmission converter is composed of three-phase six bridges. Each phase bridge is composed of two bridge arms. Each bridge arm is cascaded by bridge arm reactors and several sub-modules. made. The number of submodules contained in a single bridge arm is represented by Nsm. The sub-module is the basic unit of the converter, and the topology of the sub-module is as follows: figure 2 As shown, it includes a DC capacitor, an upper IGBT connected in series with the DC capacitor, and a lower IGBT connected in parallel with the DC capacitor. There are diodes in the upper and lower IGBT tubes connected in antiphase and parallel with them, and the sub-module also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com