Crystal zirconium jewel ornament

A technology for zirconium gemstones and ornaments, applied in the field of crystal zirconium gemstone ornaments, can solve the problems of affecting the decorative effect, waste of raw materials, stupidity, etc., and achieve the effects of improving the decorative function of ornaments, saving raw materials and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

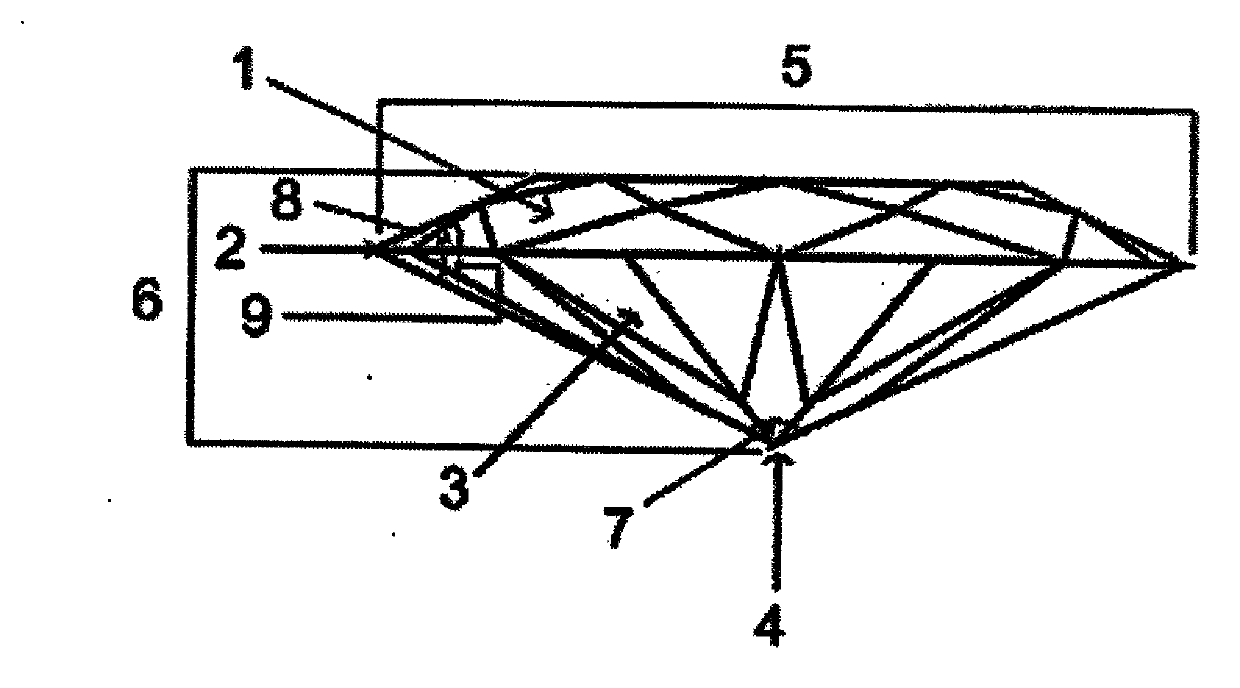

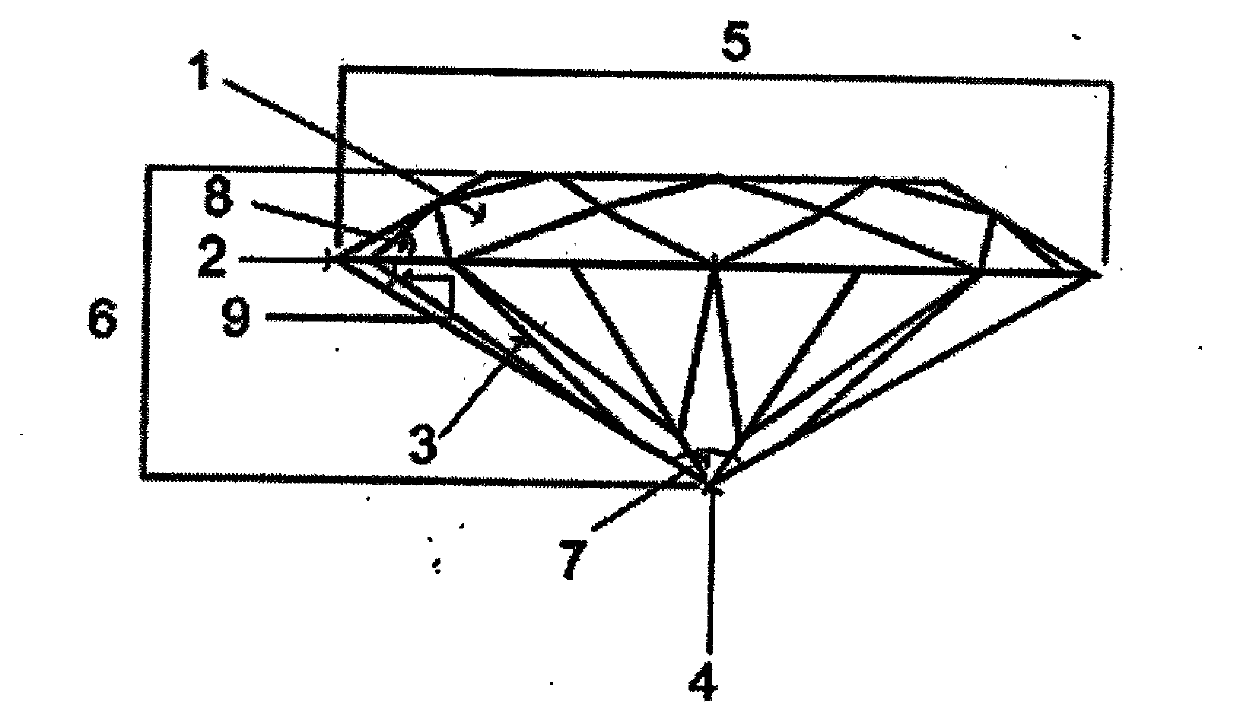

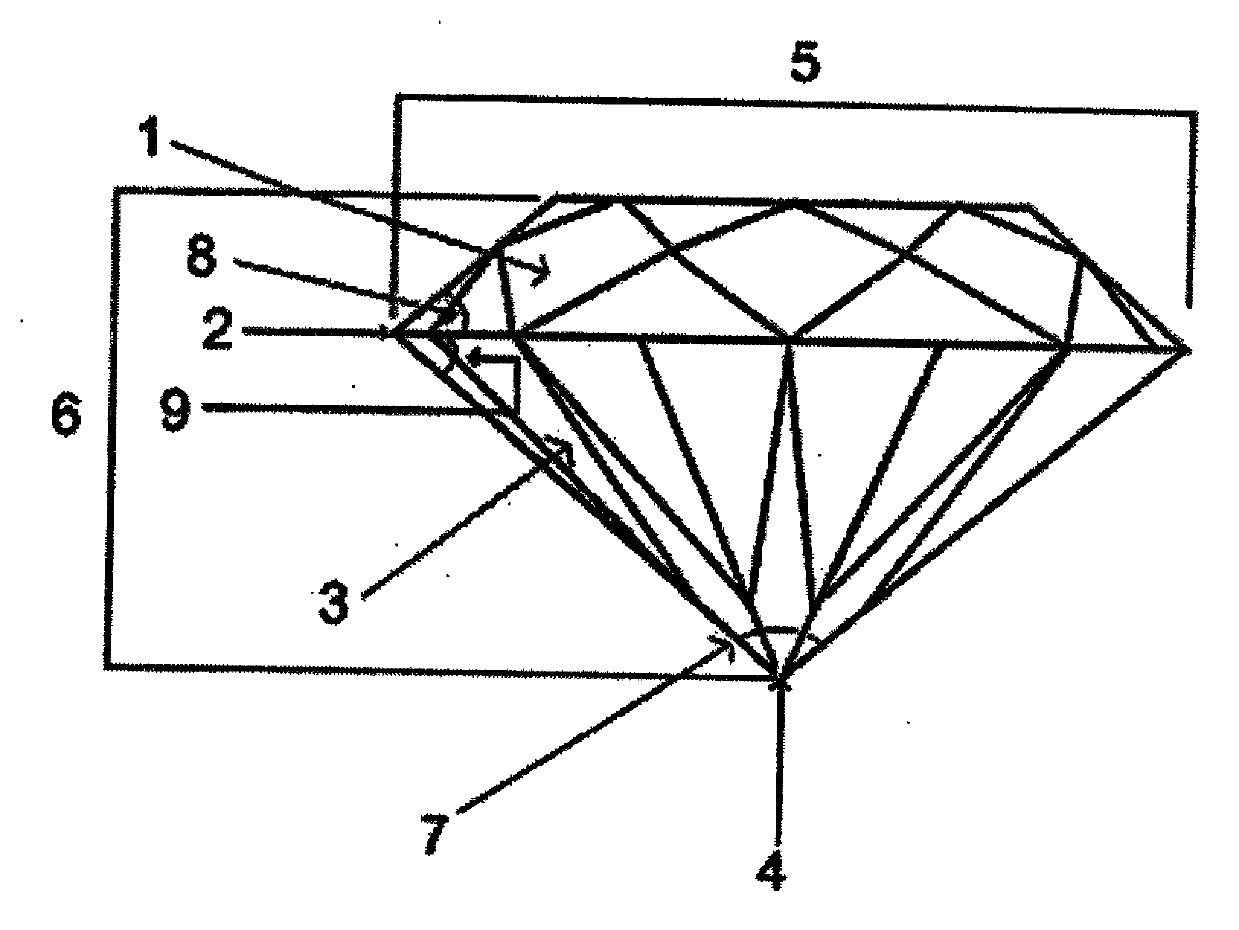

[0017] Referring to the accompanying drawings, take the round crystal zircon gemstone decoration with an average waist diameter of 10mm as an example. Take the white synthetic cubic zirconia raw material as the material, use a stone cutter to cut out the rough stone with an average waist diameter of 10.5mm, and the percentage of the vertical distance between the top of the crown table and the bottom to the average waist diameter is 50%, that is, 5.25mm, and use a shaping machine The rough stone is shaped into a rough stone with an average waist diameter of 10.15mm, and the percentage of the vertical distance between the table top of the crown 1 and the apex 4 to the average waist diameter remains unchanged, which is still 50%, that is, 5.25mm. The rough stone is polished with a polishing machine. For a round stone with an average waist diameter of 10.0mm, use an octagonal machine to polish the round stone into a percentage of the vertical distance between the top of the crown a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com