Half-thread spongy bone hollow screw

A technology of hollow screw and loose thread, applied in the direction of internal bone synthesis, fixer, fastening device, etc., can solve the problem that hollow screw cannot meet the clinical needs, achieve good holding force and stability, easy to use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to understand the technical solution of the present invention in more detail, the present invention will be specifically described below in conjunction with the accompanying drawings.

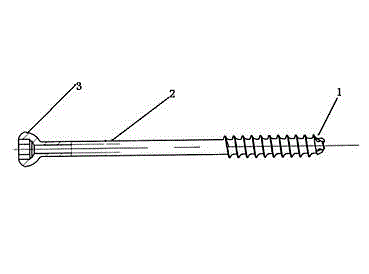

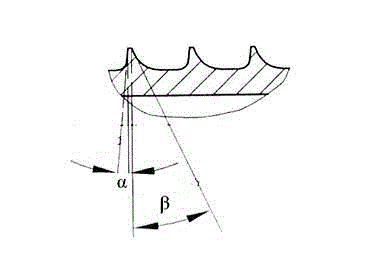

[0010] Such as figure 1 , 2 As shown, the half-thread cancellous bone hollow screw of the present invention includes a nail head 1, a nail shaft 2 and a nail tail 3, and the length of the half-thread cancellous bone hollow screw is 35-140mm. The nail shank 2 is a hollow titanium alloy shank with a through hole with a diameter of 2.2 mm inside. The nail shank 2 includes a threaded section with a length of 32 mm at the front end and a non-threaded section at the tail end. The diameter of the non-threaded section is 3.6 mm. The major thread diameter of the thread segment is 5.5mm, the minor thread diameter is 3.5mm, the pitch is 1.75mm, the thread thickness is 0.1mm, and the working angle α of the tooth profile is 5 0 , tooth profile non-working angle β is 25 0 , The chamfering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com