Winding device and method of tire bead wire drawing machine

A wire take-up device and bead wire technology, which is applied in the field of bead wire wire drawing machine wire take-up device, can solve problems such as easy failure of bearings, personal and equipment injuries, and inability to continue production, so as to achieve high-speed drawing and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

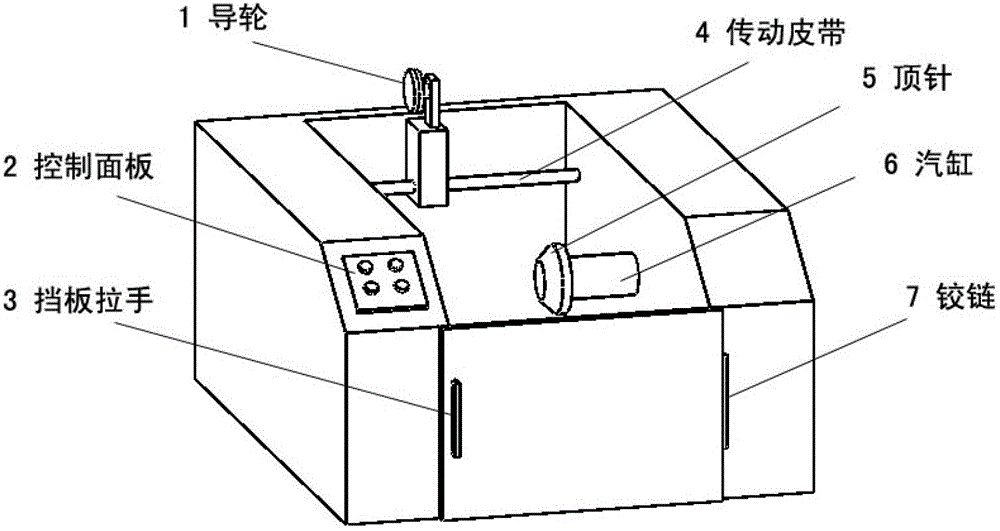

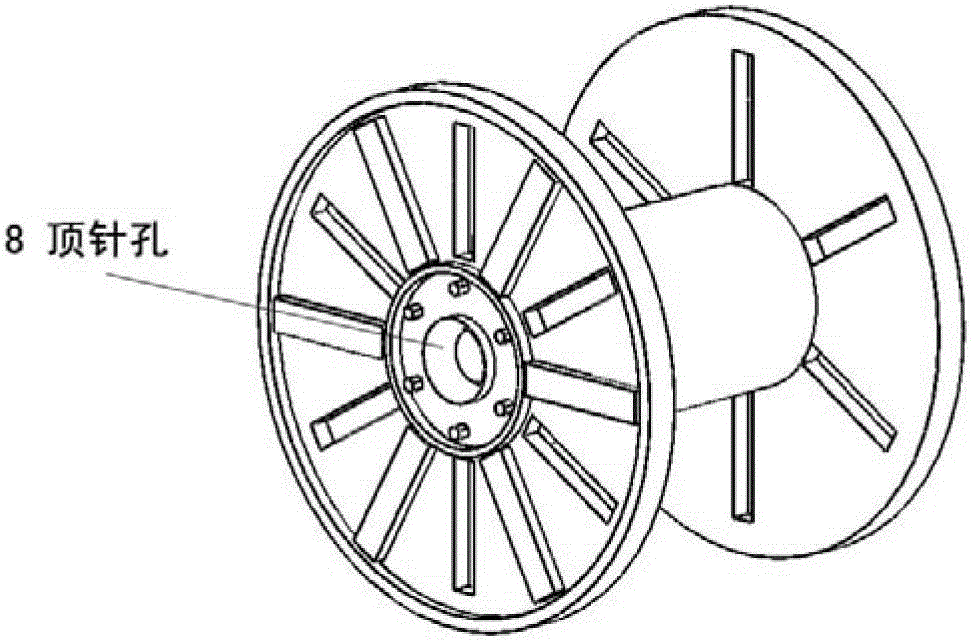

[0027] like Figure 1 to Figure 2 As shown, this patent is realized in this way: the figure 2 The I-shaped wheel shown in the present invention is placed figure 1 On the take-up device shown, the tightening device is controlled by the control panel 2, and the cylinder 6 pushes the thimble 5, so that the thimble 5 pushes into the thimble hole 8 of the I-shaped wheel. After the steel wire is drawn by the wire drawing machine, it enters the device through the guide wheel 1, and the wire arrangement signal detected by the programmable controller controls the servo motor to adjust the travel distance of the transmission belt 4 to complete the wire take-up and wire arrangement processing to prevent the wire Disordered threads are generated during the winding process, which will cause the subsequent process to be unable to use normally.

Embodiment 2

[0029] On the basis of the above-mentioned embodiments, the wire take-up device is also provided with a protective device. The hinge 7 is installed behind the base of the wire take-up device, and the baffle is closed by the baffle handle 3 before the operation process, so as to prevent the After the steel wire breaks caused by factors, the broken end of the steel wire will hurt the operator.

Embodiment 3

[0031] On the basis of the above embodiments, a wire take-up device for a bead wire drawing machine includes a placing part for vertically placing the I-shaped wheel, wherein the placing part is provided with a thimble 5 that is pushed into the thimble hole 8 of the I-shaped wheel A transmission belt 4 is arranged above the placement part, and a guide wheel 1 for controlling the entry of steel wires is arranged on the transmission belt 4 .

[0032] Preferably, further, it further includes a programmable controller installed in the wire take-up device to detect the wire-discharging signal and the wire-receiving signal.

[0033] Preferably, further, the control panel 2 is arranged on the left side of the wire take-up device.

[0034] Preferably, further, a hinge 7 including a hinge steel wire is installed behind the base of the wire take-up device.

[0035] Preferably, further, it also includes a baffle handle 3 arranged behind the abutment to close the baffle.

[0036] Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com