Printing soaking device

A thermal device and printing technology, which is applied in printing, printing machines, transfer printing, etc., can solve the problems of uneven heating of clothes, affect the printing effect, and the inability to adjust the temperature of clothes, so as to achieve uniform temperature and improve the effect of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

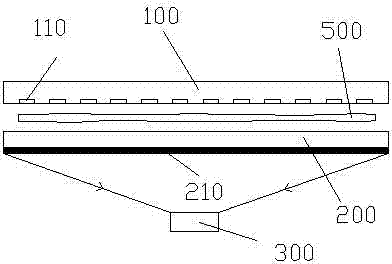

[0016] refer to figure 1 , in this embodiment, the printing heat soaking device includes a metal soaking plate 100 for heating the surface of the clothes 500, the heating surface of the metal soaking plate 100 is provided with a zoned heating structure, and the metal soaking plate 100 covers the Above the clothes 500, the clothes 500 are set on a printing platform, the printing platform is composed of a temperature-sensitive plate 200 corresponding to the metal vapor chamber, and the bottom of the temperature-sensitive plate 200 is coated with liquid crystal ink. layer 210, an imaging device 300 for monitoring the liquid crystal ink coating 210 is provided under the temperature sensing plate 200, and the imaging device 300 is connected to a control module (not shown) for data connection, and the control module controls the In the zoned heating structure, the control module converts the color of the liquid crystal ink coating 210 into temperature data, and controls the heating ...

Embodiment 2

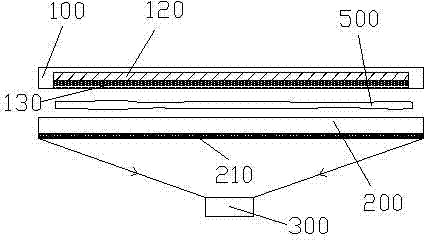

[0019] refer to figure 2 , only the district heating structure in the first embodiment is changed as follows: the metal vapor chamber 100 is provided with a thermal radiation heating source 120, and the thermal radiation heating source 120 is covered with a liquid crystal screen 130, and the liquid crystal screen 130 is electrically connected with the control module.

[0020] The liquid crystal screen 130 adopts a liquid crystal display mode similar to that of a common black and white screen computer, and the control module controls the display of the liquid crystal screen 130 to control the radiation intensity of the thermal radiation heating source 120 transmitted through the liquid crystal screen.

[0021] In the above printing heat soaking device, the heat radiation heating source 120 is a carbon crystal electric heating plate, which has the characteristics of small size and high thermal efficiency.

[0022] The principle of the above-mentioned embodiment 1 and embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com