Self-adaptive flexible airplane assembly device and method

An aircraft assembly and adaptive technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of reduced aircraft accuracy, long production preparation cycle, and many intermediate links, so as to enhance core competitiveness and provide economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

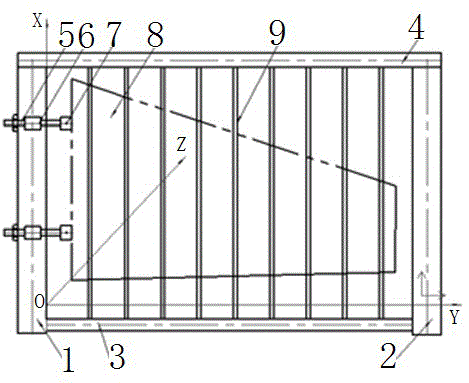

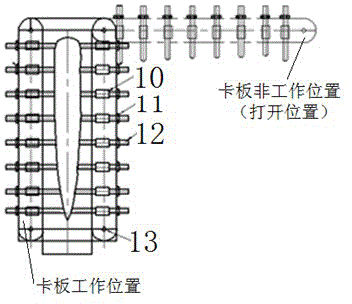

[0020] An adaptive flexible aircraft assembly device such as Figure 1 to Figure 2 As shown, it includes: the left column of the mold frame 1, the right column of the mold frame 2, the lower beam 3, the upper beam 4, the positioning device for the assembly joint of the structural parts (including the guide driving mechanism 5, the workpiece positioning mechanism 6, and the wing connecting mechanism 7), Aircraft structure 8, clamping plate 9, positioning column positioning mechanism 10, positioning column guiding drive mechanism 11, aircraft shape positioning column 12 and clamping plate positioning and rotating mechanism 13, and the horizontal plane YOZ formed by coordinate axes Y and Z, composed of coordinates A facade XOY formed by axes X and Y, a facade XOZ formed by coordinate axes X and Z; where:

[0021] On the facade XOY, set the left column 1 of the profile, the right column 2 of the profile, the lower beam 3, and the upper beam 4. The left and right columns are select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com