Method for processing sylvite salt mine with high mud content

A technology of potash rock salt mine and processing method, applied in the direction of alkali metal chloride and the like, can solve the difficult processing of high mud-containing potassium rock salt mine, can not solve the problems of desliming gravel, potassium chloride separation, etc. The effect of recycling, low processing cost, and reduced processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

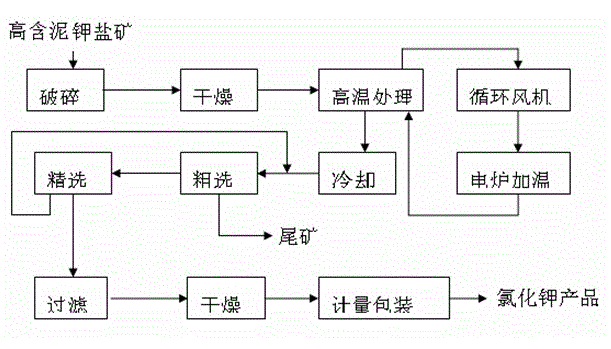

Embodiment 1

[0028] A processing method of high-mud potash rock salt ore is characterized in that the following steps are performed:

[0029] 1) Send the high-mud potassium salt ore crushed to a particle size of 0.15-0.3mm and dried in a vibrating fluidized bed at 200°C for 10 minutes into a fluidized roasting furnace, roast at 600°C for 20 minutes, cool to room temperature, and roast At the same time, the gas from the fluidized roaster is collected by the dust collector, sent to the electric heater by a high-temperature fan to increase the temperature, and then returned to the fluidized roaster to heat the ore powder to realize circulating air supply;

[0030] 2) The roasted material in step 1) is subjected to conventional rough flotation to obtain overflow and underflow, and the underflow is sent to the tailings dam;

[0031] 3) The overflow in step 2) is subjected to conventional fine flotation to obtain overflow and underflow, and the underflow returns to the rough flotation in step 2)...

Embodiment 2

[0034] A processing method of high-mud potash rock salt ore is characterized in that the following steps are performed:

[0035] 1) Send the high-mud potash rock salt ore crushed to a particle size of 0.15-0.3mm and dried in a vibrating fluidized bed at 300°C for 5 minutes into a fluidized roasting furnace, roast at 250°C for 90 minutes, and cool to room temperature to obtain Roasting material, at the same time, the gas from the fluidized roaster is collected by the dust collector, sent to the electric heater by a high-temperature fan to increase the temperature, and then returned to the fluidized roaster to heat the ore powder to realize circulating air supply;

[0036] 2) The roasted material in step 1) is subjected to conventional rough flotation to obtain overflow and underflow, and the underflow is sent to the tailings dam;

[0037] 3) The overflow in step 2) is subjected to conventional fine flotation to obtain overflow and underflow, and the underflow returns to the rou...

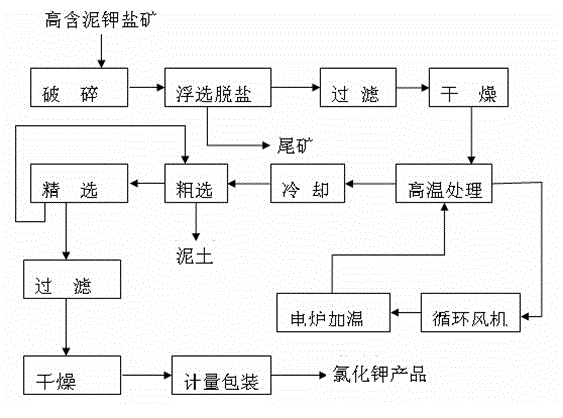

Embodiment 3

[0040] A processing method of high-mud potash rock salt ore is characterized in that the following steps are performed:

[0041] A) Perform conventional flotation desalination on high-mud potassium halite mines crushed to a particle size of 0.15-0.3 mm to obtain overflow and underflow containing sodium chloride, which will be sent to the sodium-salt dam, and sodium salt will be extracted through subsequent conventional processes ;

[0042] B) After the overflow of step A) is conventionally filtered and dried, it is sent to a fluidized roaster, roasted at 400°C for 40 minutes, cooled to room temperature, and the roasted material is obtained. At the same time, the gas from the fluidized roaster is dedusted. After the dust is collected by the dust collector, it is sent to the electric heater by a high-temperature fan to increase the temperature, and then returns to the boiling roaster to heat the ore powder to realize circulating air supply;

[0043] C) The roasted material in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com