Dynamic polycarboxylic acid cement dispersing agent, preparation method and application thereof

A technology of cement dispersant and polycarboxylic acid, which is applied in the field of concrete admixture, can solve the problems of inaccurate control of the initial fluidity and later fluidity of concrete, insufficient number of superplasticizer molecules, and increase of concrete cost, so as to reduce the cost of concrete Cost, slump loss increase mitigation, and the effect of improving water reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

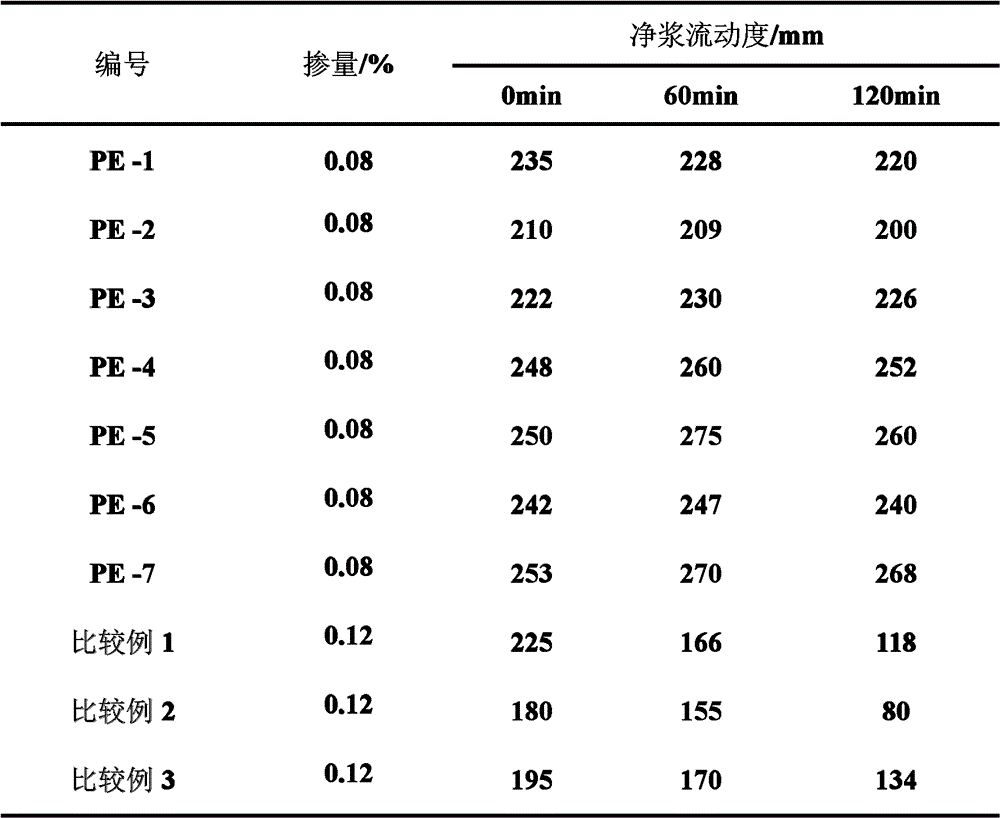

Embodiment 1

[0043] In the glass reactor equipped with thermometer, stirrer, dropping funnel and nitrogen inlet pipe, add 350g deionized water, add 560gA-1 (0.08mol) simultaneously, purging reaction vessel with nitrogen while stirring, and be warming up to Dissolve at 30°C, then add 5g of hydrogen peroxide (effective concentration: 30%), and stir evenly. Then mix 182.4g B-1 (0.8mol), 1.8g mercaptoacetic acid, 2.07g 3-mercaptopropionic acid, and 70g water, stir to form a uniform monomer aqueous solution, and drop it into the reactor for 2 hours. , and dropwise add 55g of the aqueous solution containing 7g L-ascorbic acid at the same time, the time of dropping is about 2h, after the dropwise addition is completed, the insulation reaction is 2h, then add 10g of the aqueous solution containing 0.7g L-ascorbic acid in the reaction bottle, and continue to insulate for 1h, Cool to room temperature, add alkali to neutralize to pH 7.0, and obtain an orange-yellow transparent liquid with a solid con...

Embodiment 2

[0045] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, add 250 g of deionized water and 500 g of A-2 (0.5 mol) at the same time, purging the reaction vessel with nitrogen while stirring, and raising the temperature Dissolve at 50°C, then add 2 g of hydrogen peroxide (effective concentration: 30%), and stir evenly. Then 225g of B-2 (1.25mol), 3.7g of 3-mercaptopropionic acid, and 100g of water were mixed together, stirred to form a uniform monomer aqueous solution, which was added dropwise to the reactor for 6 hours, and 100g of The aqueous solution containing 0.6g sodium formaldehyde sulfoxylate, the time of dropping is about 6h, after the dropwise addition is completed, keep warm for 2h, then add 30g aqueous solution containing 0.07g sodium formaldehyde sulfoxylate to the reaction bottle, and continue to keep warm for 1h, cool Bring to room temperature, add alkali to neutralize to a pH value of 7.7, and obtain an orange...

Embodiment 3

[0047] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen inlet tube, add 730g of deionized water, and simultaneously add 300g of A-2 (0.3mol) and 480g of A-3 (0.2mol), while stirring The reaction vessel was purged with nitrogen, and the temperature was raised to 60° C. to dissolve, then 1.2 g of hydrogen peroxide (effective concentration: 30%) was added, and stirred evenly. Then 270g of B-3 (1.5mol), 4.6g of mercaptoacetic acid, and 200g of water were mixed, stirred to form a uniform monomer aqueous solution, which was added dropwise to the reactor for 5 hours, and 100g of 0.9 The aqueous solution of g L-ascorbic acid, the dropping time is about 5h, after the dropwise addition, keep warm for 2h, then add 20g aqueous solution containing 0.1g L-ascorbic acid to the reaction bottle, keep warm for 1h, cool to room temperature, add alkali And until the pH value is 6.8, an orange-yellow transparent liquid with a solid content of 48.6% and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com