Polycarboxylic superplasticizer and application thereof

A technology of superplasticizer and polycarboxylic acid, which is applied in the field of polycarboxylic acid cement concrete dispersant, can solve the problems of increasing concrete cost, reducing concrete flow capacity, reducing the effect, etc., and reducing the impact of sulfate ions on it. Effect, slump loss good, slump loss mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

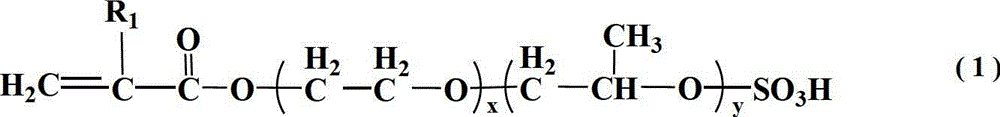

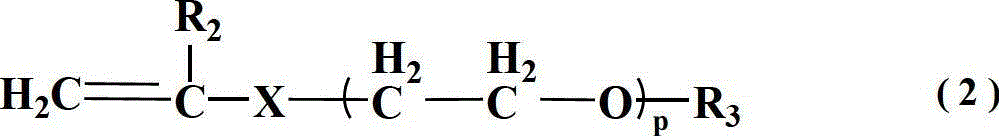

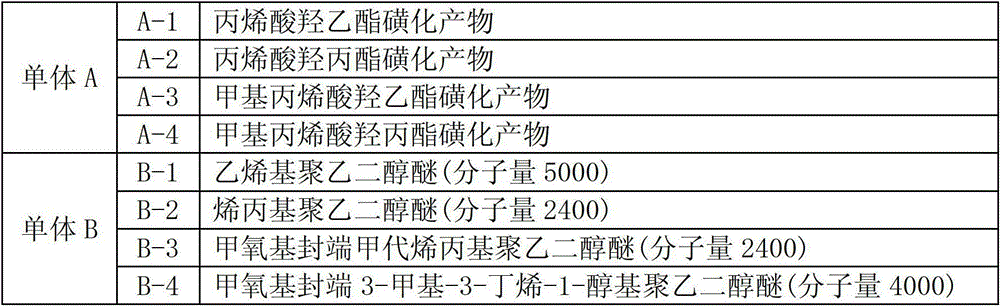

Method used

Image

Examples

Embodiment 1

[0042] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, add 250 g of deionized water and 400 g of B-1 (0.08 mol) at the same time, purging the reaction vessel with nitrogen while stirring, and raising the temperature Dissolve at 30°C, then add 10 g of hydrogen peroxide (mass concentration: 30%), and stir evenly. Then 155.2g A-1 (0.8mol), 1.6g mercaptoacetic acid, 1.84g 2-mercaptopropionic acid, and 70g of water are mixed, stirred to make a uniform monomer aqueous solution, which is added dropwise to the reactor, and the dropwise addition time is 2h, and at the same time, add 40g of aqueous solution containing 7g of L-ascorbic acid dropwise, and the dropping time is about 2h. After the dropwise addition, keep warm for 2h, then add 10g of aqueous solution containing 0.7g of L-ascorbic acid to the reaction bottle, and continue to keep warm for 1h , cooled to room temperature, and neutralized to pH 7.0 by adding alkali to obt...

Embodiment 2

[0044] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, add 400 g of deionized water and 240 g of B-2 (0.1 mol) at the same time, purging the reaction vessel with nitrogen while stirring, and raising the temperature Dissolve at 60°C, then add 0.4 g of hydrogen peroxide (mass concentration: 30%), and stir evenly. Then mix 48.5gA-1 (0.25mol), 0.74g 3-mercaptopropionic acid, and 100g water, stir to form a uniform monomer aqueous solution, and drop it into the reactor for 4 hours. 100g of an aqueous solution containing 0.225g of L-ascorbic acid was added for about 4 hours. After the addition, the reaction was incubated for 2 hours, and then 10 g of an aqueous solution containing 0.025g of L-ascorbic acid was added to the reaction bottle, and the temperature was continued for 1 hour, and cooled to room temperature. Add alkali to neutralize to pH 6.8 to obtain a light yellow transparent liquid with a solid content of 31.4% and ...

Embodiment 3

[0046] In the glass reactor equipped with thermometer, stirrer, dropping funnel and nitrogen gas introduction tube, add 440g deionized water, add 360g B-2 (0.15mol) at the same time, purging reaction vessel with nitrogen while stirring, and heat up Dissolve at 70°C, then add 4.08g of hydrogen peroxide (mass concentration: 30%), and stir evenly. Then 156g of A-2 (0.75mol), 0.96g of 2-mercaptopropionic acid, and 200g of water were mixed, stirred to form a uniform monomer aqueous solution, which was added dropwise to the reactor for 6 hours, and 100g of The aqueous solution containing 3.76g sodium formaldehyde sulfoxylate, the time of dropping is about 6h, after the dropwise addition is completed, keep warm for 2h, then add 10g aqueous solution containing 0.4g sodium formaldehyde sulfoxylate to the reaction bottle, and continue to keep warm for 1h, cool Bring to room temperature, add alkali to neutralize to pH 7.5, and obtain a light yellow transparent liquid with a solid content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com