Water reducing agent for fabricated concrete member and preparation method of water reducing agent

A water-reducing agent and concrete technology, which is applied in the field of water-reducing agent and its preparation for prefabricated concrete components, can solve the problems of poor material discharge in the blanking process, affecting the construction progress, delamination and segregation, etc., so as to improve the cohesion effect, The effect of improving the slow release effect and improving the slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

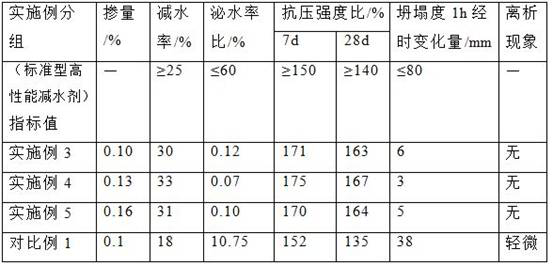

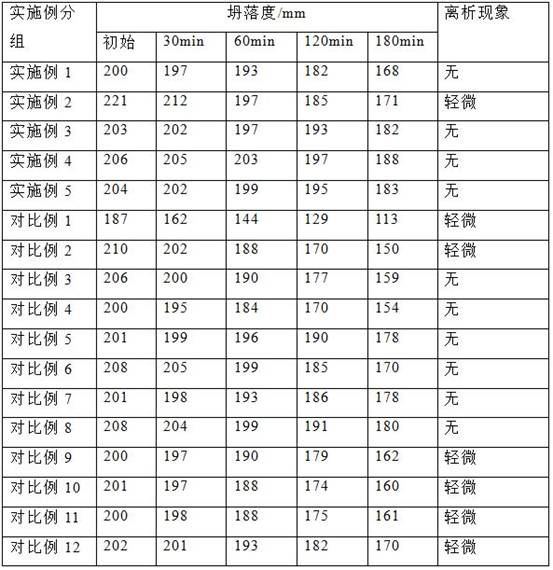

Examples

Embodiment 1

[0036] This embodiment provides a water reducing agent for assembling a concrete member, the preparation of the water reduction agent comprises allyl polyoxyethylene ether (molecular weight of 400-2400), soy acid anhydride, ethyl acrylate, 6 - Acrylaminoic acid, glycol butter, its molar ratio of 1: 0.08: 0.15: 0.1: 0.2.

[0037] The preparation method of the above water repellent includes the following steps:

[0038] (1) Heat 6-acrylalaine heating to 100 ° C, then mixing concentrated sulfuric acid is uniform, and the addition of concentrated sulfuric acid is 1% of the total reactant, then adding glycol butyl butyl butter, stirring at 110 ° C. The esterification reaction was carried out under conditions, the reaction time was 5 h, and the product was obtained;

[0039] (2) 50% of the allyl polyoxyethylene ether, soy acid anhydride, and deionized water (added amount is polyoxyethylene ether, and the total mass of both soy acid anhydride) is added to the reactor, and then the temper...

Embodiment 2

[0042]Based on the first embodiment, the present embodiment also provides a method for using a water reduction agent for assembling a concrete member, and a uniform, water reduction agent, and dispersant are mixed with the dispersant. The amount is 0.1%, 0.8%, and then the gelation material and aggregate are added, and then the mixing water is added to stir well, it can be discharged.

[0043] The active ingredient of the dispersant is amphoteric polymer, and the preparation of the amphoteric polymer comprises vinyl ether, 3-carboxy-N, N, N-trimethyl-2-propylene-1-ammonium chloride, N, N, N- Trimethyl-9-octadene-1-ammonium chloride, oleic acid, its molar ratio of 1: 0.1: 0.3: 0.4.

[0044] The preparation method of the above-mentioned amphoteric polymer includes the steps of:

[0045] S1, 3-carboxy-N, N, N-trimethyl-2-propylene-1-ammonium chloride is mixed with deionized water, formulated into a solution of 30% mass concentration, n, n, n- Trimethyl-9-octadene-1-ammonium chloride ...

Embodiment 3

[0050] Based on the example 2, the present embodiment also provides a method of preparing a dispersant in a method of use of the above-mentioned water repellent, and the specific step is: taking the prepared amphoteric polymer solution, concentrated under reduced pressure, and then The vacuum is dried under 40 ° C to dry the water content ≤ 2%, and the solid powder is obtained; the obtained solid powder and the starch, the porous ceramic powder is mixed in a mass ratio of 1: 0.4: 10, and is dispersed in a 1000R / min dispersion. Then, the sodium alginate material (3% injection amount) is sprayed, and then the powder is obtained after drying.

[0051] Sodium alginate materials include 10 parts of sodium alginate, 2 partial talc, 3 parts of phospholipids, 120 denominates.

[0052] The rest is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com