Smelting method of high-strength IF steel

A smelting method and high-strength technology, applied in the field of low-cost and high-efficiency production of high-cleanliness and high-strength IF steel, can solve problems such as the inability to meet the cleanliness of molten steel and the matching of production rhythms at the same time, shorten the RH refining cycle, reduce OB oxygen blowing, and reduce The effect of smelting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

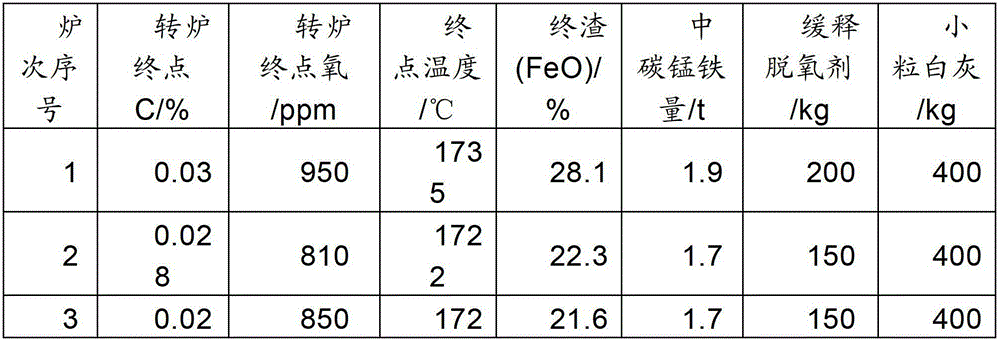

[0023] In the following, the smelting method of the high-strength IF steel provided by the embodiment of the present invention will be further explained in combination with 6 furnaces of molten steel in a certain steelmaking plant.

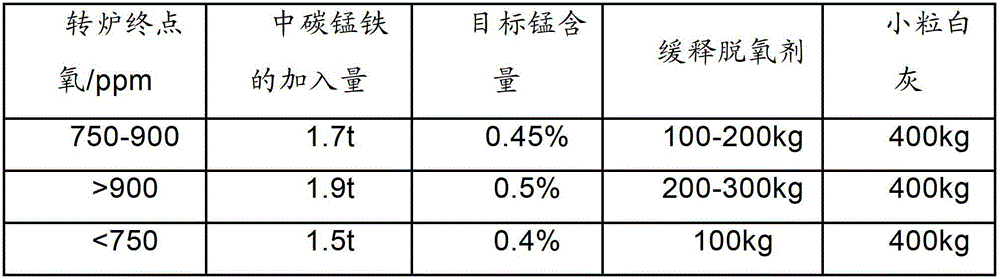

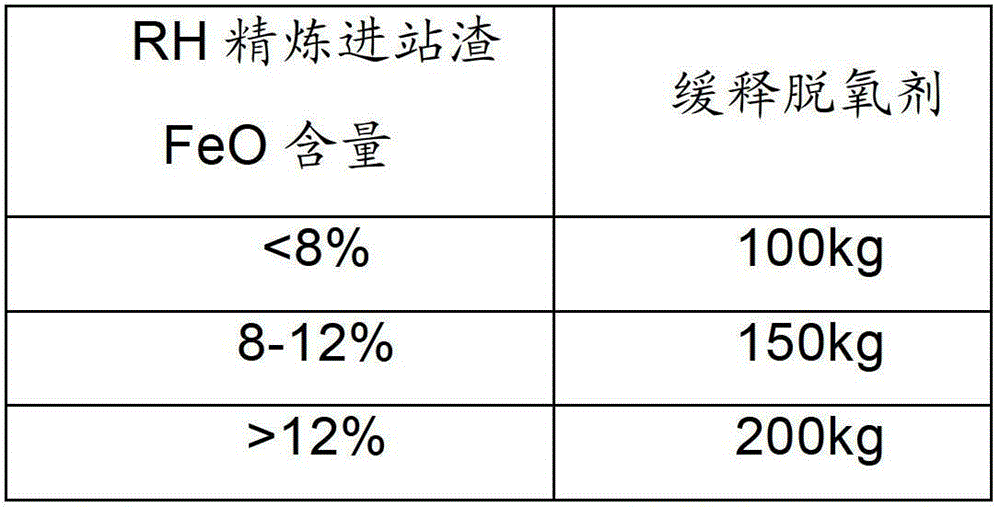

[0024] In the smelting method of high-strength IF steel provided by the present invention, the target composition of the smelted steel is: [%C]<0.003, [%Mn]: 1.5-1.7, [%P]: 0.07-0.09, [%S]<0.015 , [%Nb]: 0.015~0.030, [%Ti]: 0.015~0.025, [%B]: 0.0005~0.0015, [%N]<0.004, this smelting method includes: adding desulfurized molten iron into dephosphorization and decarburization double Combined with the converter for smelting, the temperature and composition of the end point of the converter and the amount of slag alloy added during the tapping process are controlled. The amount of slag alloy added is shown in Table 3. The order of adding slag and alloy is small-grained lime, medium-carbon ferromanganese and slow-release deoxidizer. Small-grain lime an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com