Novel flat type PECVD (Plasma Enhanced Chemical Vapor Deposition) equipment and gas channel connecting hole structure thereof

A flat-plate, hole-structured technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems affecting the stability of PECVD equipment, silicon nitride film stability, and unqualified silicon wafers, increasing equipment maintenance. cost and other issues, to achieve the effect of reducing equipment maintenance costs, prolonging equipment use time, and reducing chromatic aberration films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

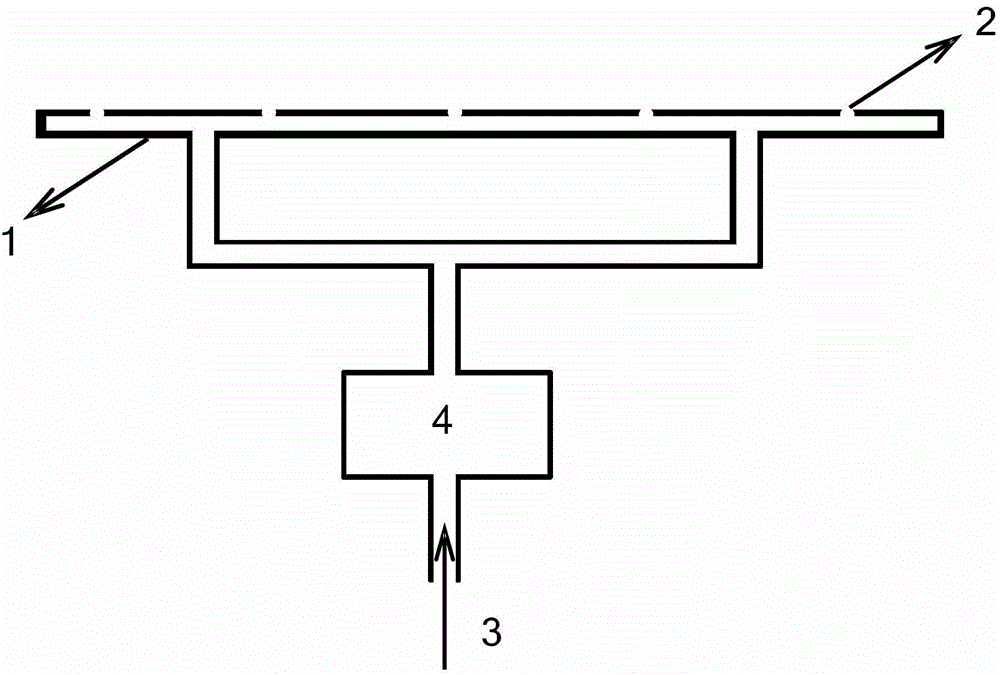

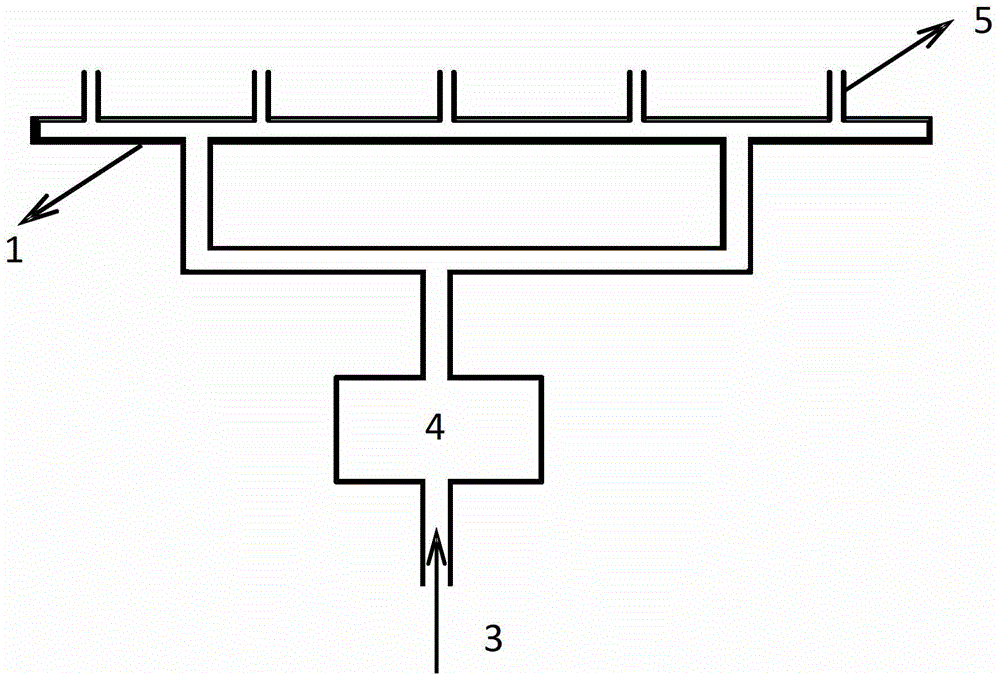

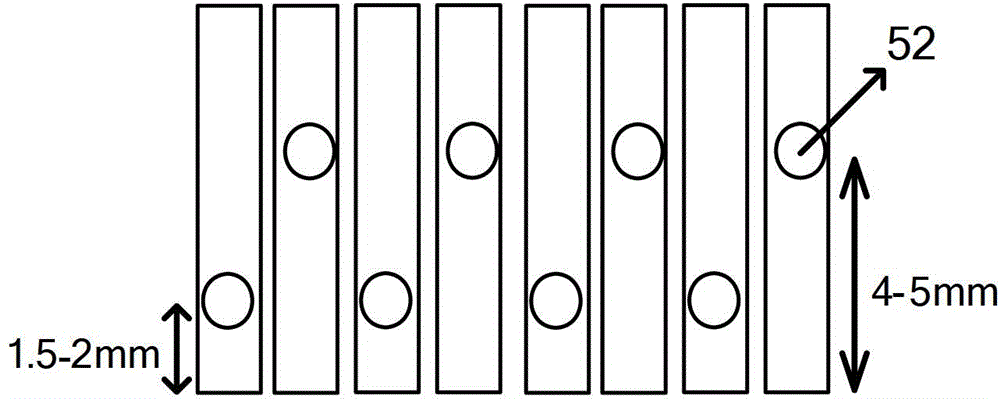

[0029] The core of the present invention is to disclose a novel flat plate type PECVD gas path connection hole structure, which reduces the probability of blockage of special pores during equipment operation and reduces the influence of special pores on the thickness of deposited silicon nitride film.

[0030] For ease of understanding, the technical terms involved in the present invention are now explained as follows:

[0031] PECVD: Plasma Enhanced Chemical Vapor Deposition (Plasma Enhanced Chemical Vapor Deposition) uses microwaves to ionize the gas containing the constituent atoms of the film to form plasma locally, and the plasma is chemically active and easy to react. desired film.

[0032] Special gas: SiH fed into flat PECVD 4 and NH 3 .

[0033] Inter-chip color difference: the film thickness and color difference between the coated sheets on the same graphite boat.

[0034] The following will clearly and completely describe the technical solutions in the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com