Ballast-installation and track-regulation measurement quick positioning method for ballast track engineering

A positioning method and track technology, which can be applied to tracks, measuring instruments, track maintenance, etc., can solve the problems of many steps and restricting the efficiency of measuring and positioning work, simplifying the working steps, reducing the probability of measurement errors and human errors, and achieving high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

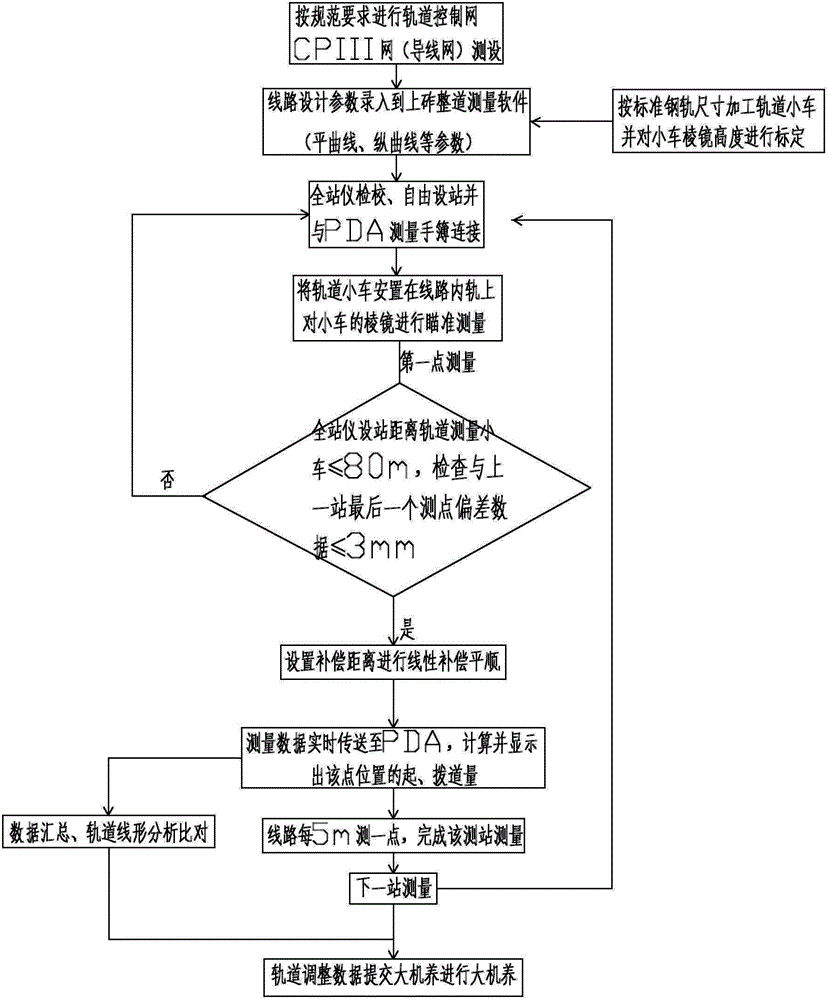

[0033] The ballasted track project proposed by the present invention requires supporting hardware and software support when it is implemented on the spot. The hardware part mainly includes: track trolley, total station, PDA measuring hand book and data connection line etc. The rail trolley is a trolley with a prism that can walk on the rail according to the geometric dimensions of the national railway construction standard rail. It uses the groove surface of the two pulleys and the convex surface of the rail to make the pulley and the rail fit precisely to eliminate measurement errors. It can be pushed and walked freely and smoothly on the railway rails. The prism is mounted on the frame support of the track trolley.

[0034] The software part is: "Survey of whole track on ballast" software, which is a special software that can be connected with the total station through the data communication port of the total station to realize data sharing and linear calculation.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com