Assembly method of bridge-building machine at exit of tunnel connected with bridge

A bridge building machine and exit technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as huge temporary earthwork volume, save earthwork volume and shorten the installation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

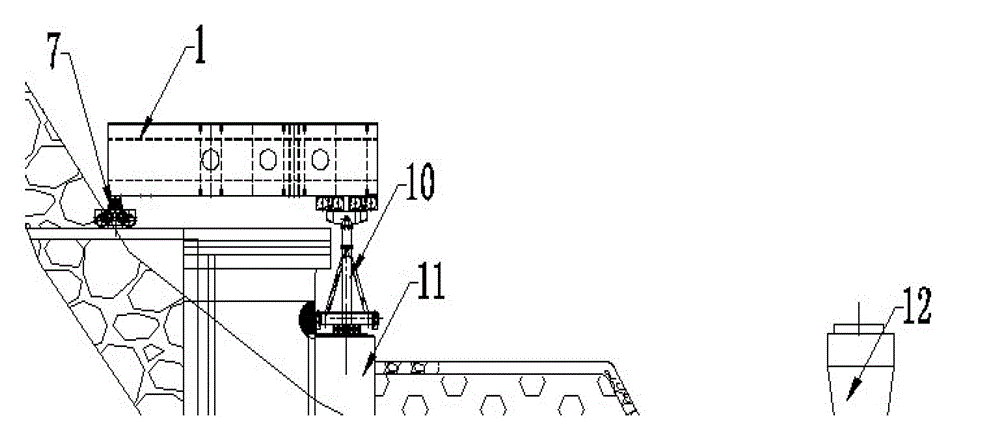

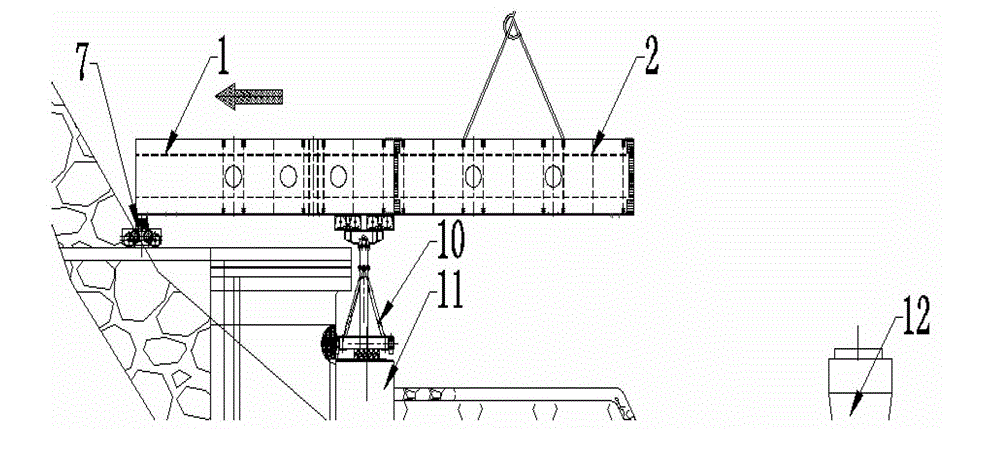

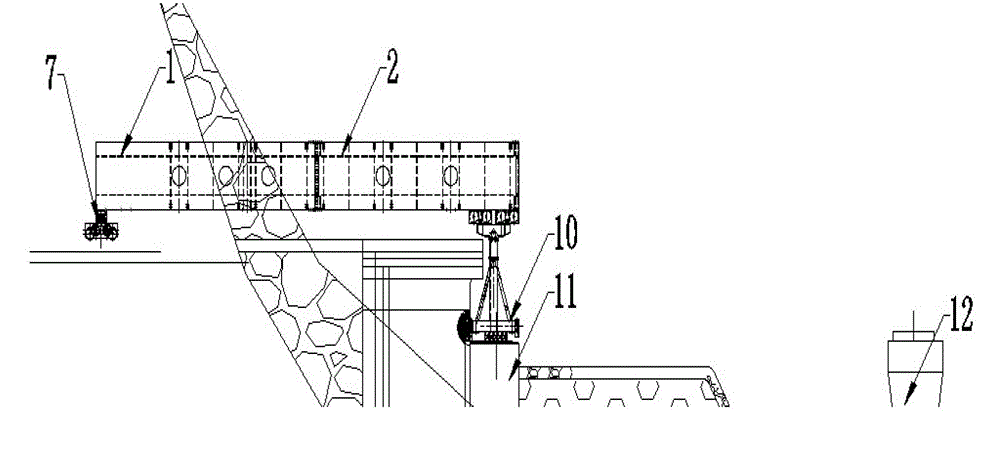

[0031] A method for assembling a bridge building machine at the exit of a tunnel connected by bridges and tunnels, comprising the following steps:

[0032] (1) Reserve the work site on the left and right sides of the 0# platform and the 1# pier and roll it flat. The range is about 10 meters wide on the left and right sides of the center line of the 0# platform and the 1# pier. Use mortar to level the bearing action point on the top of 1# pier;

[0033] (2) Install the slipping traveling wheel set at the bottom of the main beam of the second section and the main beam of the third section;

[0034] (3) Install the electric running motor mechanism of the rear outrigger of the first section of the main beam of the bridge building machine at the bottom of the inverted arch of the tunnel, install the front outrigger on the 0# platform, and use the car to lift the first section of the main beam and place it on the rear outrigger electric motor mechanism On the front outriggers of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com