Weaving sleeve pipe type fiber reinforce plastic (FRP) rib and preparation method thereof

A casing and pre-forming technology, which is used in mining equipment, earth-moving drilling, sheet pile walls, etc., can solve the problems of insufficient circumferential strength of FRP bars, and achieve the effect of good circumferential performance indicators and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further elaborated and illustrated below in conjunction with specific embodiments.

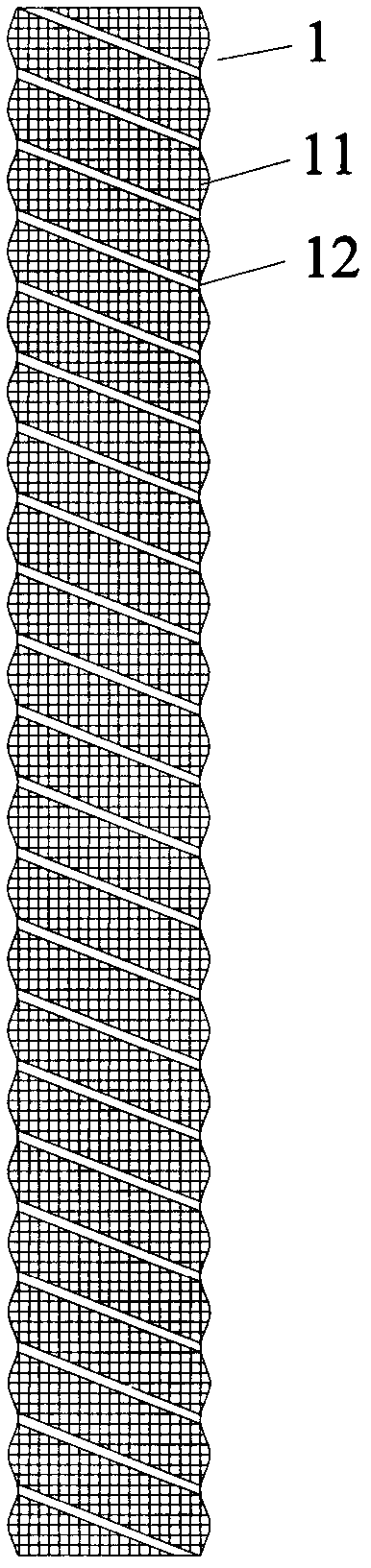

[0017] figure 1 It is a structural schematic diagram of a braided sleeve-type FRP tendon 1 according to an embodiment of the present invention. The FRP tendon 1 is in the shape of a rod, and there are protrusions 11 on the surface of the FRP tendon 1, which are distributed on the surface of the FRP tendon 1 in the form of a pattern. , the pattern is plain weave, twill weave or satin weave; the FRP tendon 1 also has a helical structure 12, and the helical structure is arranged transversely on the FRP tendon 1 and is continuous.

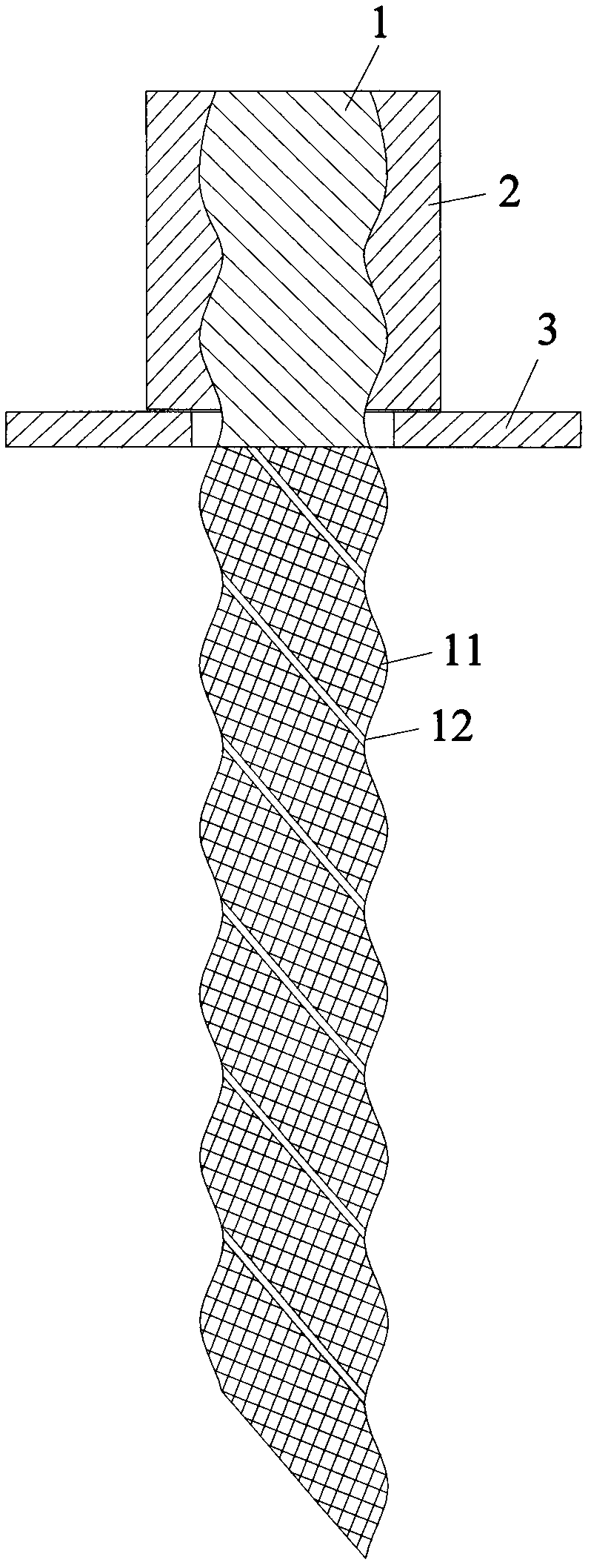

[0018] figure 2 It is a structural schematic view of another embodiment of a braided sleeve type FRP tendon of the present invention when it is applied, wherein it includes an FRP tendon 1, a nut 2 and a backing plate 3, and one end of the FRP tendon 1 has a sharp angle, so that The FRP bar is convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com