Step type excavating method for large unloading loose rocky side slope

A rocky slope and construction method technology, which is applied in excavation, infrastructure engineering, climate change adaptation, etc., can solve problems such as poor slope forming quality, easy drill drop, and reduced slope stability, so as to improve the formation Quality and construction efficiency, ensuring integrity and stability, and preventing collapse accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

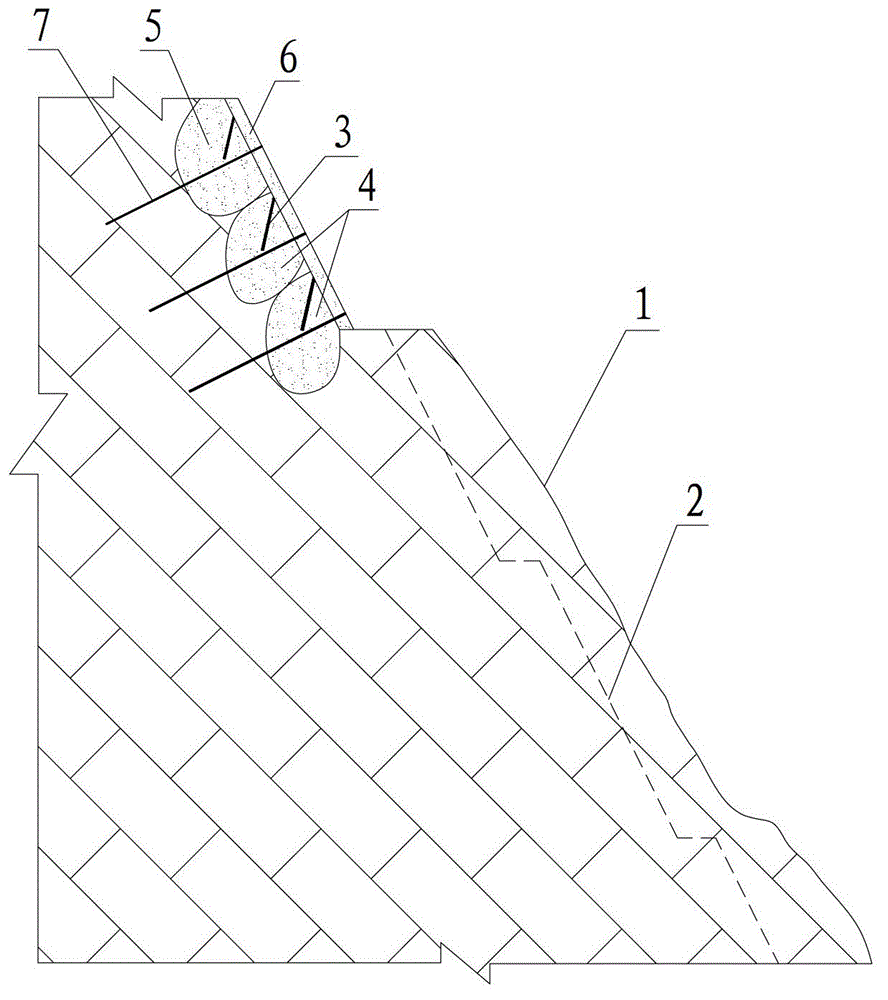

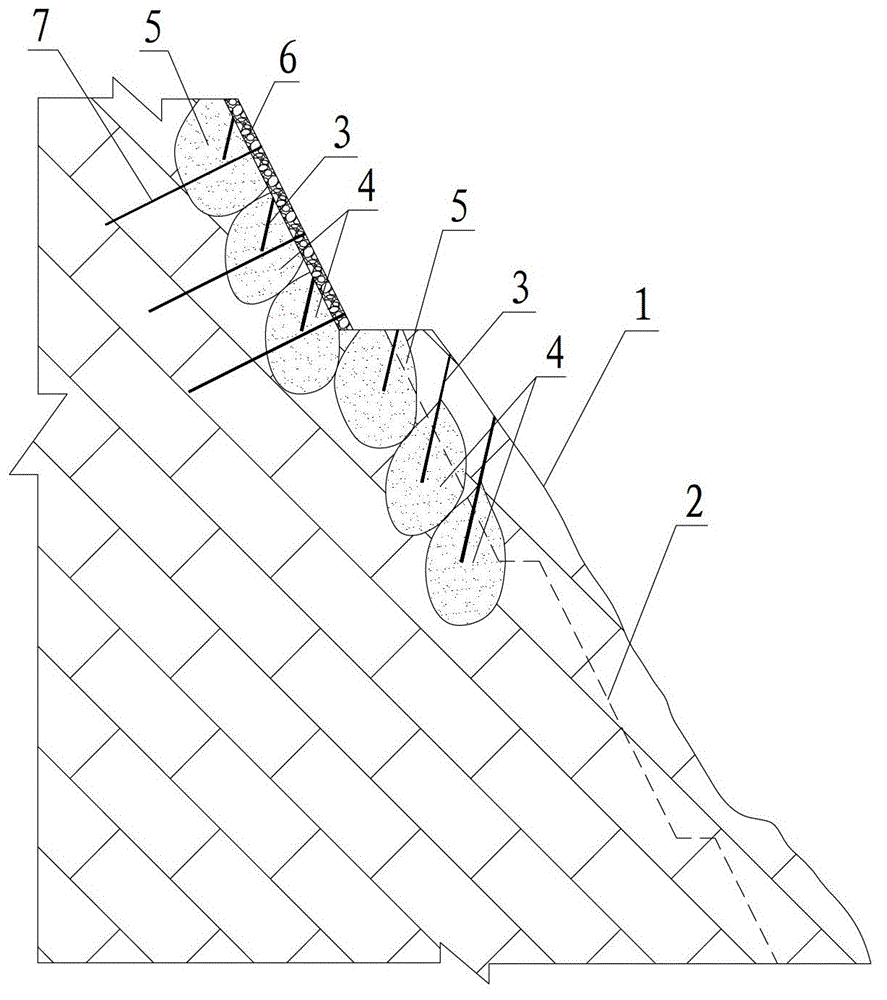

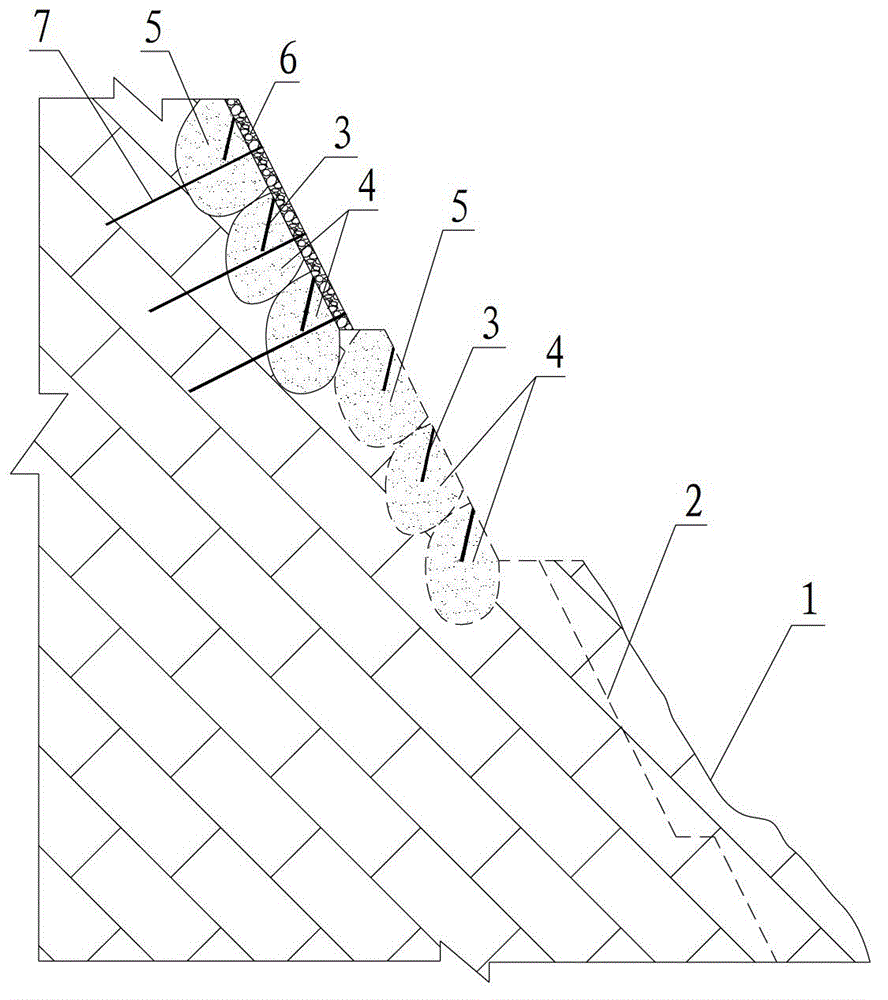

[0028] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown is an existing pre-blasting excavation technology provided by the present invention to excavate a large unloaded loose rock slope, which can effectively improve the surface rock mass of the large unloaded loose rock slope. Integrity and stability, and at the same time, it can prevent the slope surface rock mass from collapsing due to pre-blasting construction, which is a stepped excavation construction method for large unloading and loose rock slopes. The step-type excavation construction method includes the following steps,

[0029] 1) Drilling grouting holes, from the natural slope line 1 of the uppermost slope step to be excavated to the design excavation contour line 2 of the slope, the inclined drilling depth exceeds the grouting hole 3 of the design excavation contour line 2 ;

[0030] 2) Protective grouting, pouring protective grout from the grouting hole 3 to the rock body within the designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com