Energy saving type combination upright post

An energy-saving, column technology, applied in building components, walls, buildings, etc., can solve the problems of inconvenient installation, complex on-site management, high cost, and achieve the effects of easy installation, high safety, and strong plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

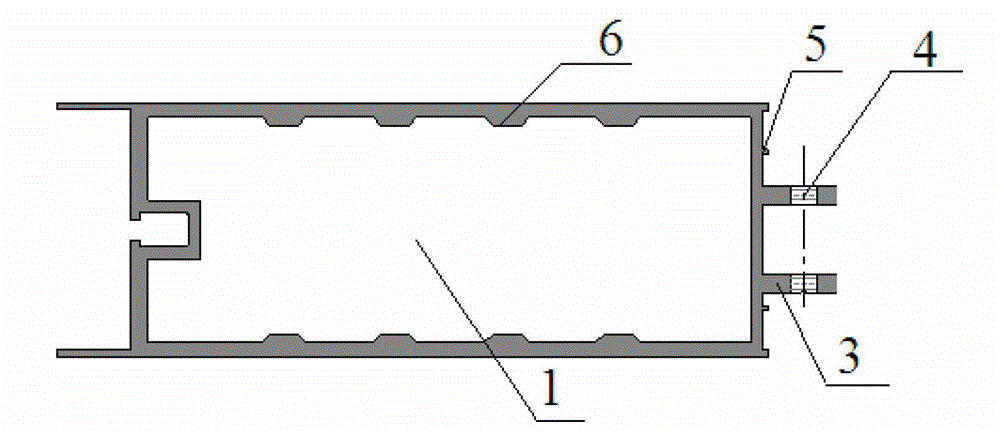

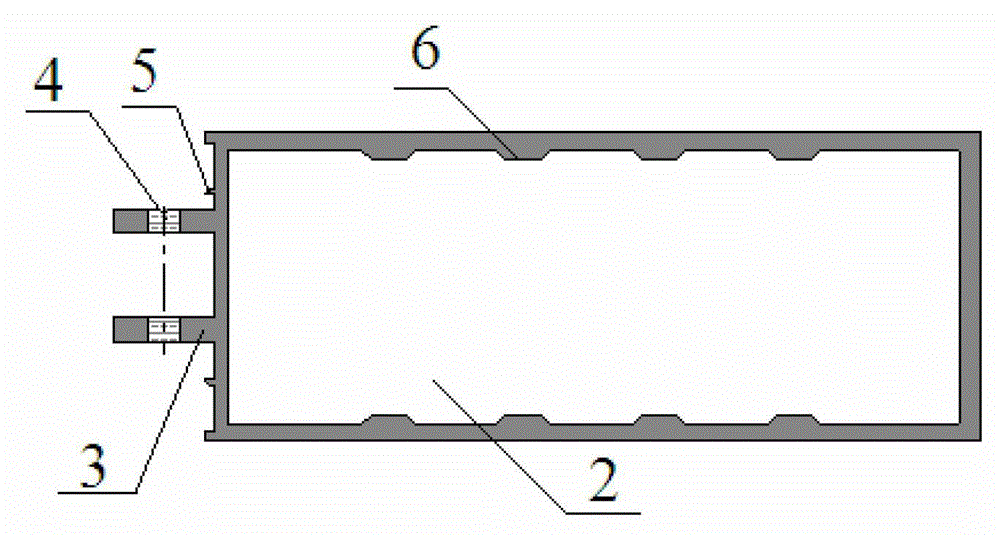

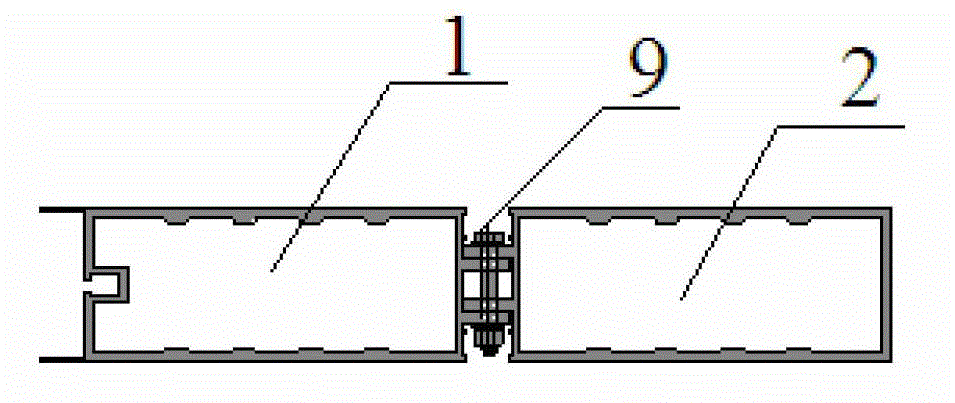

[0022] An energy-saving combined column, such as image 3 and Figure 5 As shown, the energy-saving combined column includes a head column 1, a tail column 2 and two buckle parts 7, and the structures of the head column 1 and the tail column 2 are as follows: Figure 1 ~ Figure 2 As shown, one side of the first column 1 is provided with two protruding horizontal plates 3, and one side of the tail column 2 is provided with two protruding horizontal plates 3, and these four horizontal plates 3 are interlaced so that the first column 1 and the The side of the tail column 2 is butted, and the cross plate 3 is provided with a bolt through hole 4, and the bolt 9 penetrates the bolt through hole 4 to connect the head column 1 with the cross plate 3 of the tail column 2. The structures of the two buckle parts 7 are as follows: Figure 4 As shown, the two buckle parts 7 are semi-frame structures, and both sides of the two buckle parts are provided with buckle protrusions 8 . The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com