Water stopping device for water inrush borehole drilling

A technology of water-stop device and water-stop casing, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc. Long curing time and other problems, to achieve the effect of saving construction materials, short setting time, and reducing the difficulty of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

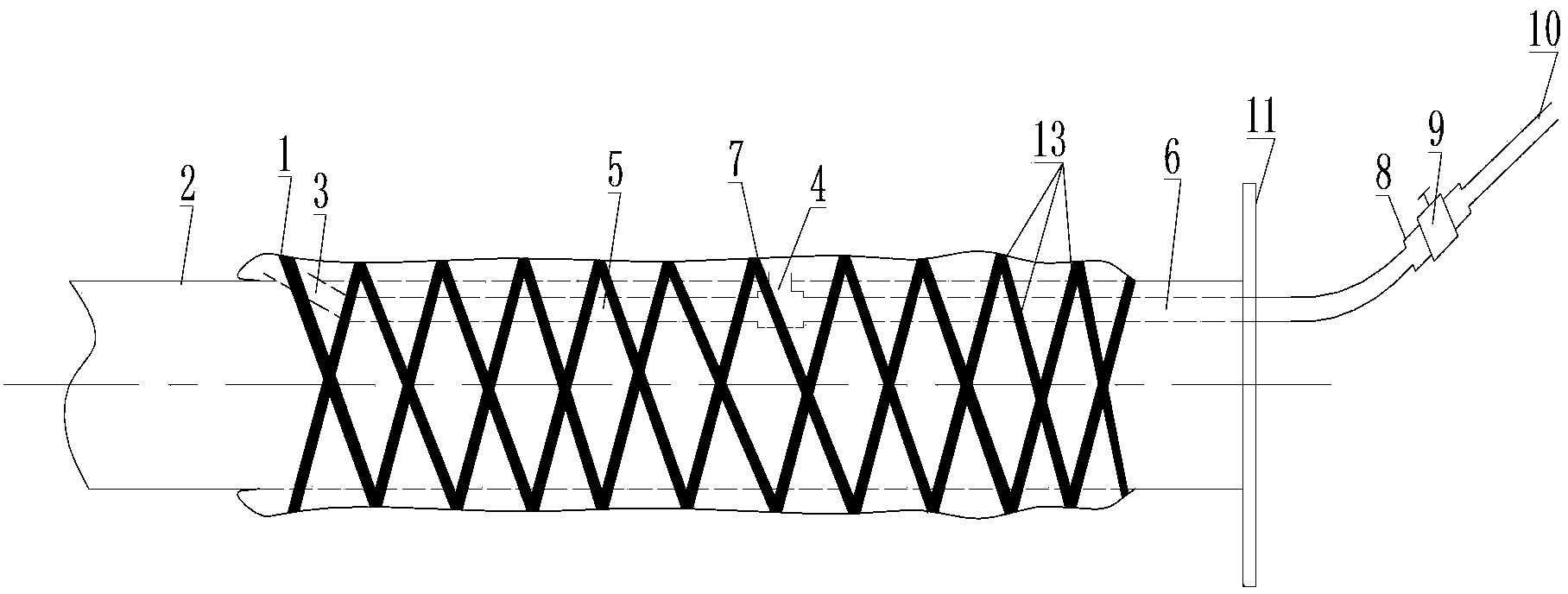

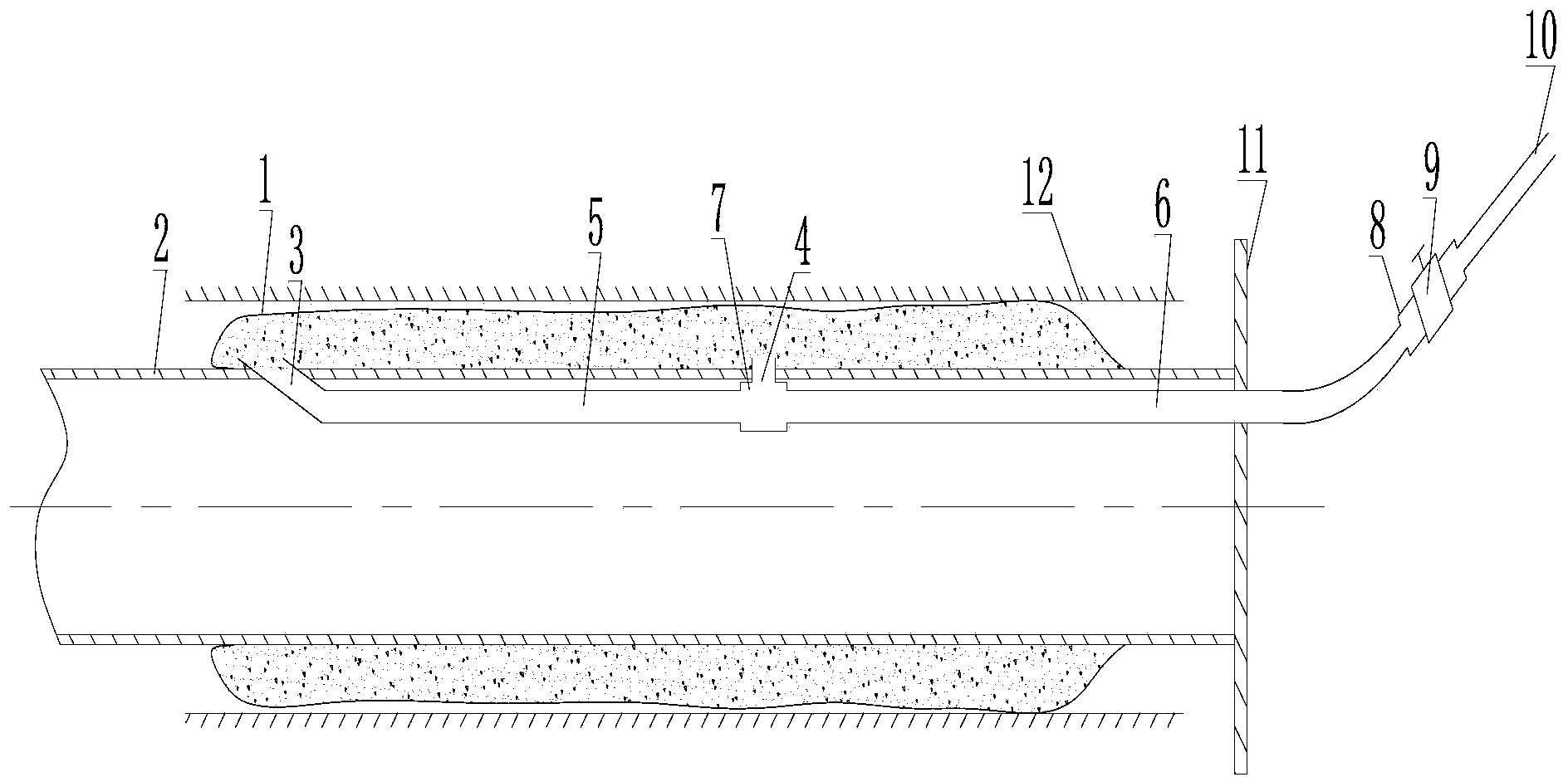

[0027] A water-inrush drilling water-stopping device, comprising a water-stop casing 2 and a small grouting pipeline 10, the walls of the water-stop casing 2 near both ends are respectively provided with a slurry outlet I3 and a slurry outlet II4, the The round holes of the grout outlet I3 and the grout outlet II4 are on the same straight line in the axial direction, the grout outlet I3 and the grout outlet II4 are connected with the small grouting pipe, and the small grouting pipe is arranged in the water-stop casing, and the small grouting pipe and the small grouting pipe are connected to each other. The grouting pipeline 10 is connected, the small grouting pipeline 10 is connected with the grouting pump, and the periphery of the water-stop casing 2 is provided with a cylindrical mold bag 1 after processing, and the inner diameter of the mold bag 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com