Light-emitting diode (LED) lamp bulb

A technology of LED light bulbs and LED light sources, applied in the field of light bulbs, can solve the problems of high production cost and low light utilization rate, and achieve the effects of low production cost, high light utilization rate and good temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

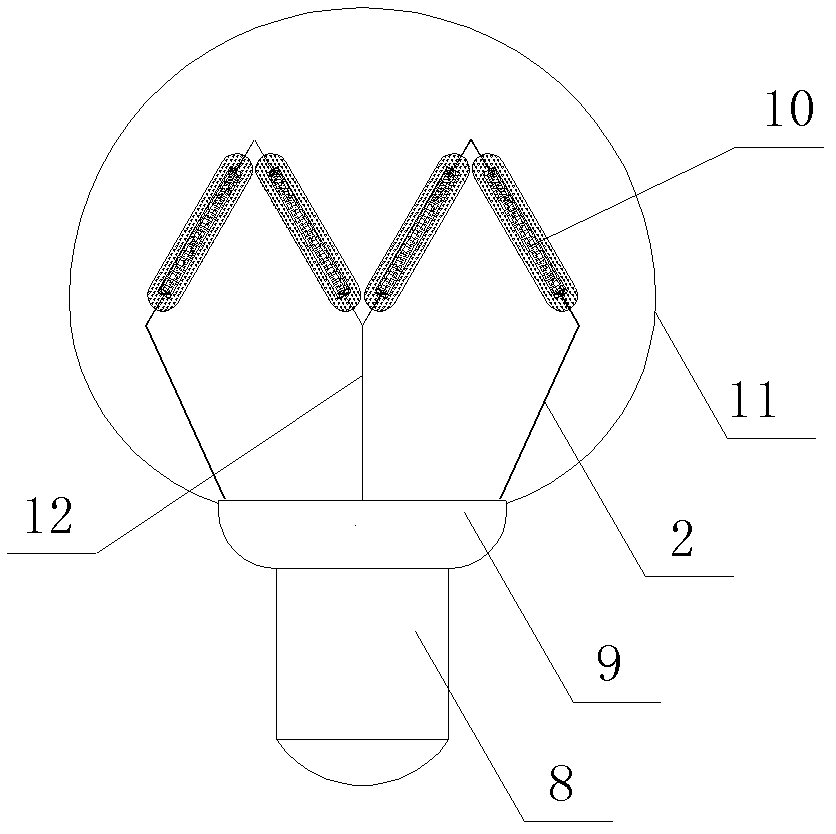

[0021] Such as figure 1 , image 3 with Figure 4 The shown LED light bulb includes a lamp holder 8, a lamp housing 9, at least two wires 2, a constant current power supply, a lampshade 11 and a plurality of LED light sources 10, the lamp housing 9 is installed on the lamp holder 8, and the lampshade 11 is installed on the lamp housing 9, the wire 2 is connected to the lamp holder 8 through a constant current power supply, and the wire 2 is used for connecting the LED light source 10 and the lamp holder 8 and also supports the LED light source 10. The LED light source 10 between the two wires 2 is located in the inner cavity of the lampshade 11, and the best position of the LED light source 10 is at the center of the inner cavity of the lampshade 11, which has high luminous efficiency.

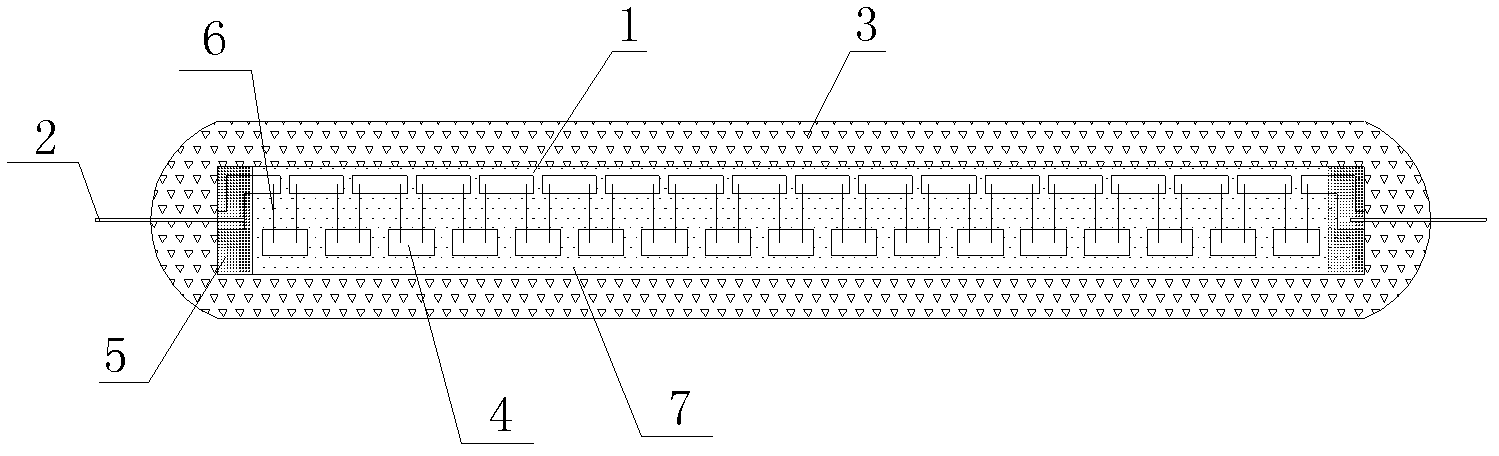

[0022] The LED light source is composed of chip 4, insulating glue 3, fluorescent powder 7, gold wire 6, wire 2, adhesive 5 and flexible PCB board 1. Phosphor powder 7 is coated on the chip...

Embodiment 2

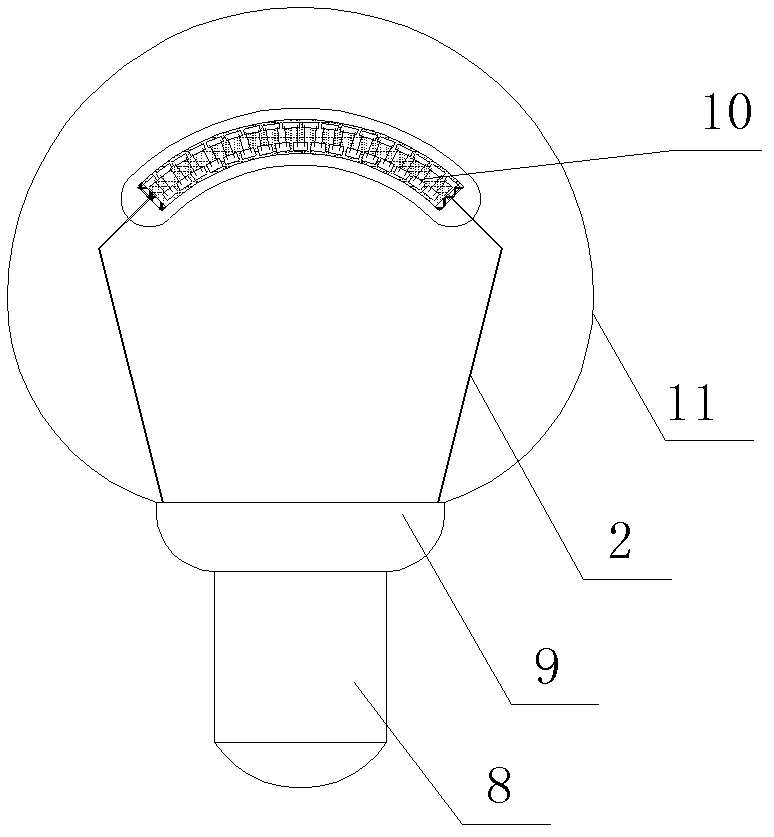

[0025] Such as figure 2 , image 3 with Figure 4 In the shown LED light bulb, except for the shape of the flexible PCB board 1 and the arrangement shape of the LED light sources 10, the number of the LED light sources 10 can be single or multiple, and the other structures are the same as those of the first embodiment.

[0026] The flexible PCB board 1 is bent in an arc shape, that is, the LED light source 10 is bent in an arc shape, which is convenient to be made into various shapes and improves luminous efficiency. Compared with Embodiment 1, where two adjacent LED light sources 10 are arranged in a V-shaped structure The number of light sources 10 used can be reduced. The flexible PCB 1 can be bent into an arc but cannot be used at an angle. After the angle is bent, the chip 4 on the flexible PCB 1 is likely to warp and cause the gold wire 6 to break, and the flexible PCB 1 is also easy to break.

[0027] The above-mentioned two embodiments are only preferred implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com