Energy-saving gas cooker with rotary heat exchange device

A technology of heat exchange device and gas cooker, which is applied in the directions of heating fuel, gaseous heating fuel, combustion method, etc., to achieve a healthy working environment, improve thermal efficiency, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

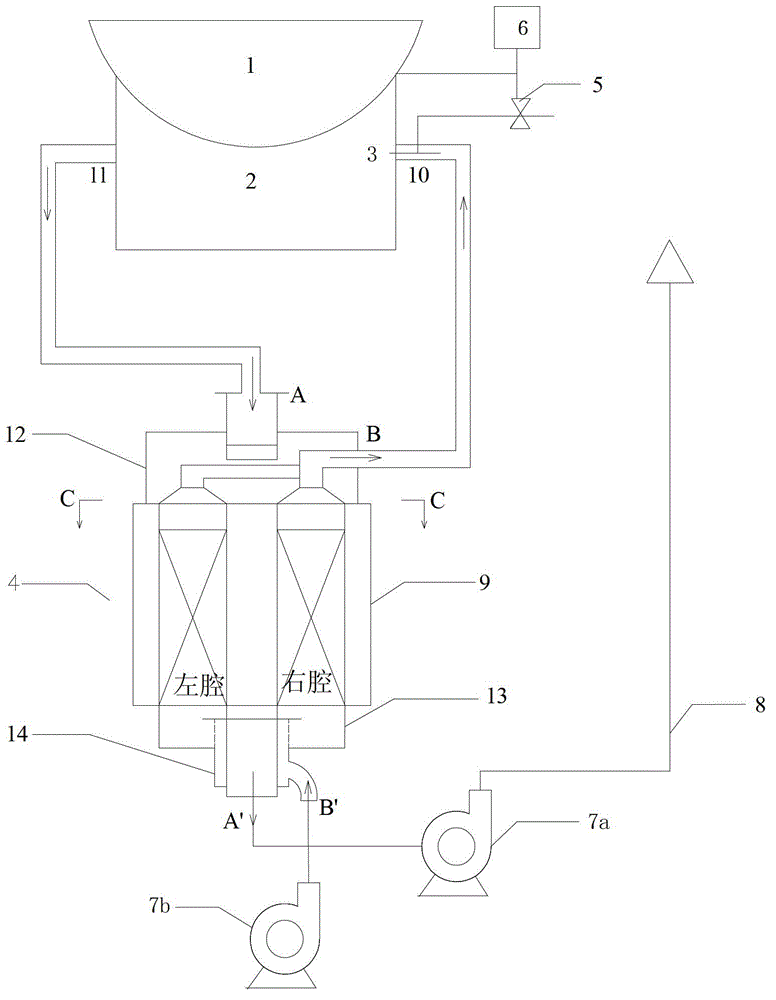

[0014] The high-efficiency and energy-saving gas cooker with rotary heat exchange device of the present invention, its preferred specific implementation is as follows figure 1 As shown, the system includes a pot 1, a furnace body 2, a burner 3, a regenerator rotary heat exchange device 4, a gas flow control valve 5, a temperature control device 6, an induced draft fan 7a, a blower 7b, and a flue exhaust duct 8.

[0015] The cooker is directly connected with the furnace body to make the whole cooker fully enclosed.

[0016] The interior of the furnace body constitutes a combustion chamber, a burner is provided on the right side of the furnace body wall, and a high-temperature flue gas outlet is provided on the left side.

[0017] The burner is provided with a high-temperature air inlet and a gas inlet.

[0018] The burner is connected with the regenerator rotating heat exchange device through the high-temperature air inlet.

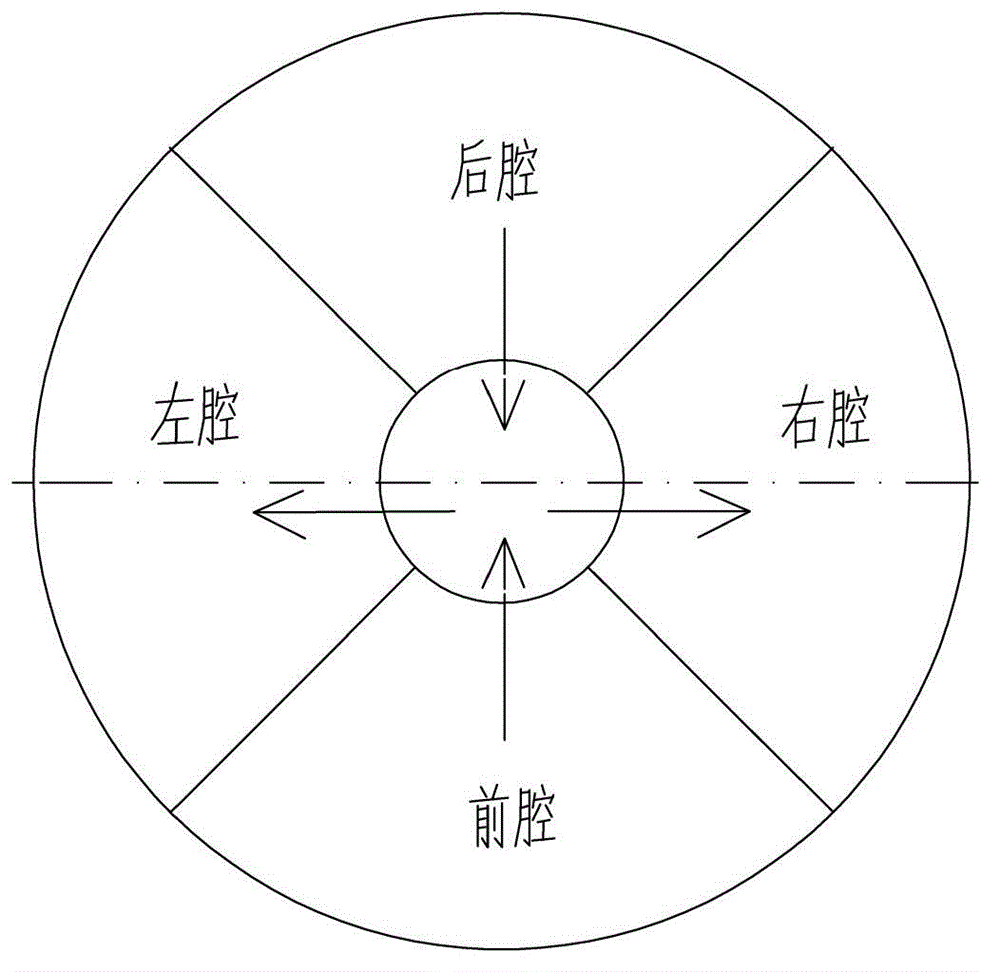

[0019] The regenerator rotary heat exchange device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com