Self-made painting drying device

A technology for drying devices and paintings, applied in drying, drying machines, painting tools and other directions, can solve problems such as incomplete range, unstable drying degree, immature technology, etc., and achieve good drying effect and structure. Simple, heat-even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

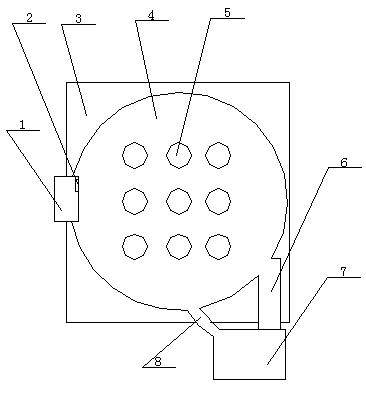

[0007] see figure 1 , the specific embodiment adopts the following technical scheme: it includes an observation window 1, a temperature detection and alarm device 2, a drying room 3, a drying ring 4, a drawing bracket 5, a hot air inlet 6, a heat sending machine 7 and a heat outlet 8; An observation window 1 is arranged on one side of the drying room 3, and a temperature detection and alarm device 2 is arranged on the observation window 1. A drying ring 4 is arranged in the drying room 3, and several painting brackets 5 are evenly arranged in the drying ring 4. The side is provided with a hot air inlet 6, the hot air inlet 6 and the heat sending machine 7, and the side of the hot air inlet 6 is provided with a heat outlet 8 connected with the heat sending machine 7.

[0008] This specific embodiment has simple structure, uniform heat, good drying effect, fast speed, and saves heat energy.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap