Online detection method for energy-saving environment-friendly laterite-nickel ore smelting shaft furnace smelting slag

A laterite nickel ore and detection method technology, which is applied in the direction of measuring devices, instruments, and analytical materials, can solve problems such as inability to adjust furnace charge formula, poor representativeness, and large errors, and achieve improved production technology, strong representativeness, and small overall errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

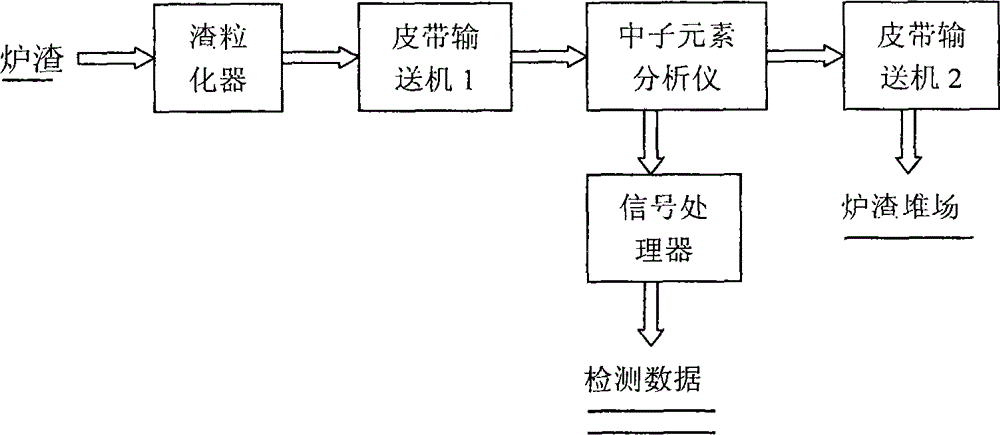

[0013] 1. Before removing the slag, check the water system, belt conveyor, neutron element analyzer system, jog operation status, if there is no abnormal problem, start the system operation, and start slag removal.

[0014] 2. The slag is taken out from the energy-saving and environment-friendly shaft furnace of the laterite nickel mine, automatically enters the granulator, undergoes forced rapid cooling, and rolls down on the belt conveyor. After cooling, the slag is controlled below 100°C.

[0015] 3. The belt conveyor sends the charge to the neutron element analyzer for analysis. Before entering the element analysis, the temperature of the slag is controlled below 60°C.

[0016] 4. The analyzer detects and analyzes according to the program, and transmits the data to the relevant receiving department.

[0017] 5. The detected slag is transported to the designated storage yard through the belt conveyor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com