Timing temperature control device for biogas

A technology of temperature control device and biogas, which is applied in the direction of temperature control by electric method, auxiliary controller with auxiliary heating device, etc., can solve the problems of high operating cost, difficult control of heating energy, and uncontrollable heating time, etc., to achieve The effect of increasing gas production rate and saving fermentation raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

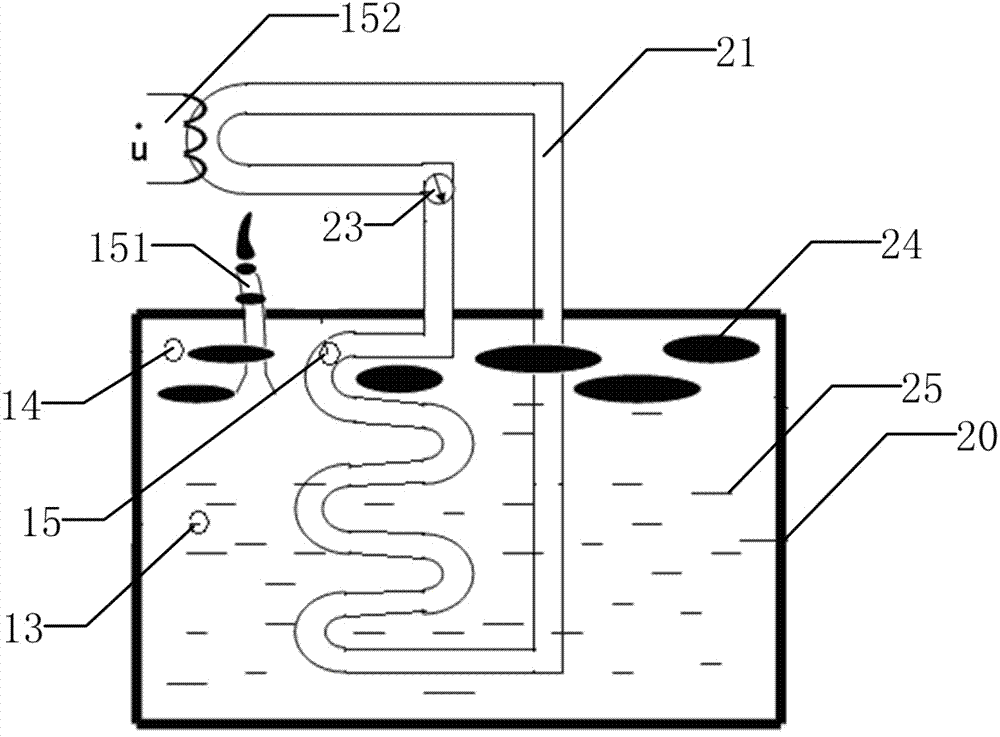

[0034] The following describes in detail the implementation of a biogas timing temperature control device of the present invention with reference to the accompanying drawings.

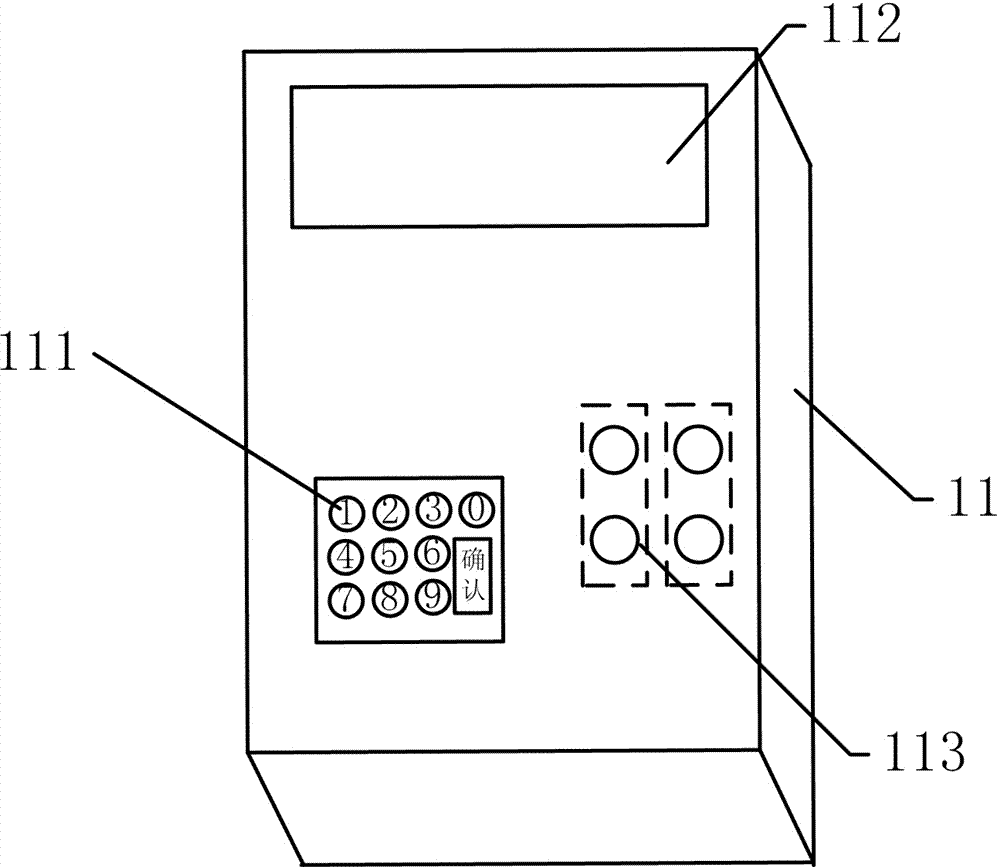

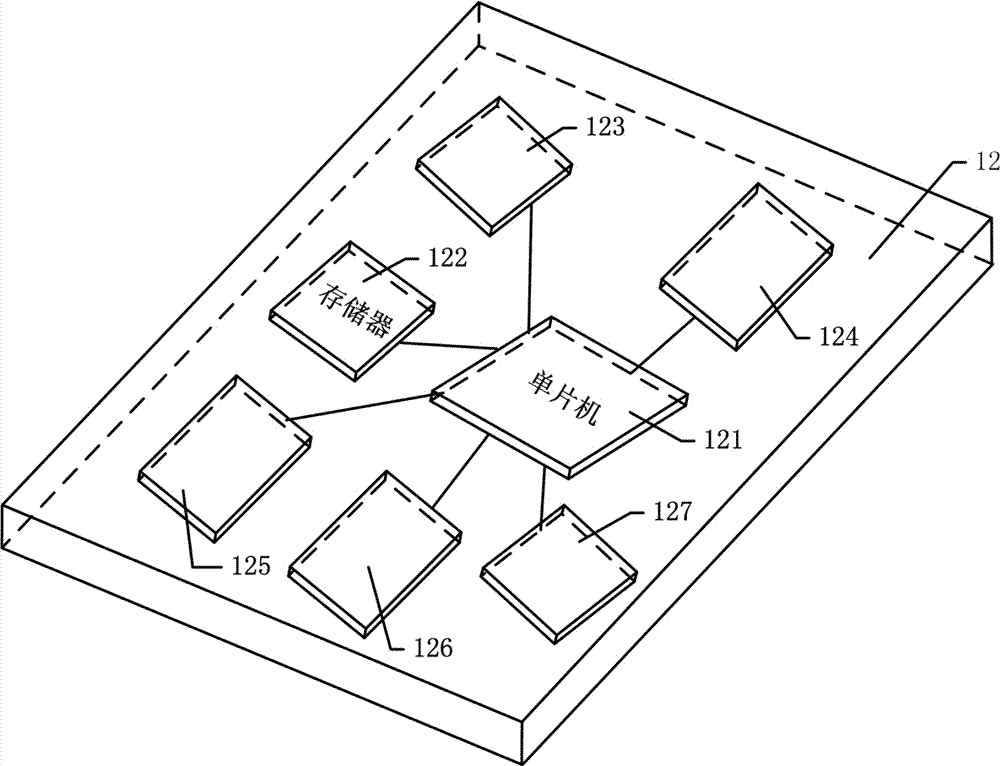

[0035] See Figure 1 ~ Figure 4 , A biogas timing temperature control device, including a box body 11 and a circuit board 12. A circuit board 12 is provided in the box 11. The circuit board 12 includes a single-chip computer 121, a memory 122, a timer (not shown), a first temperature sensor control circuit 123, a concentration sensor control circuit 124, a heating device control circuit 125, a water pump control circuit 126, and a second temperature sensor Control circuit 127.

[0036] The box body 11 includes a button group 111, which is arranged on the surface of the box body 11, and the button group 111 is connected to the single-chip microcomputer 121 for inputting time and its corresponding temperature. According to the defined different time corresponding to different relationship tables, the relev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com