Drive circuit and applicative piezoelectric actuating pump thereof

A drive circuit, piezoelectric actuation technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Inability to effectively reduce the size of the circuit board and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A typical embodiment embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention is capable of various changes in different aspects without departing from the scope of the present invention, and that the description and drawings are illustrative in nature rather than limiting the present invention.

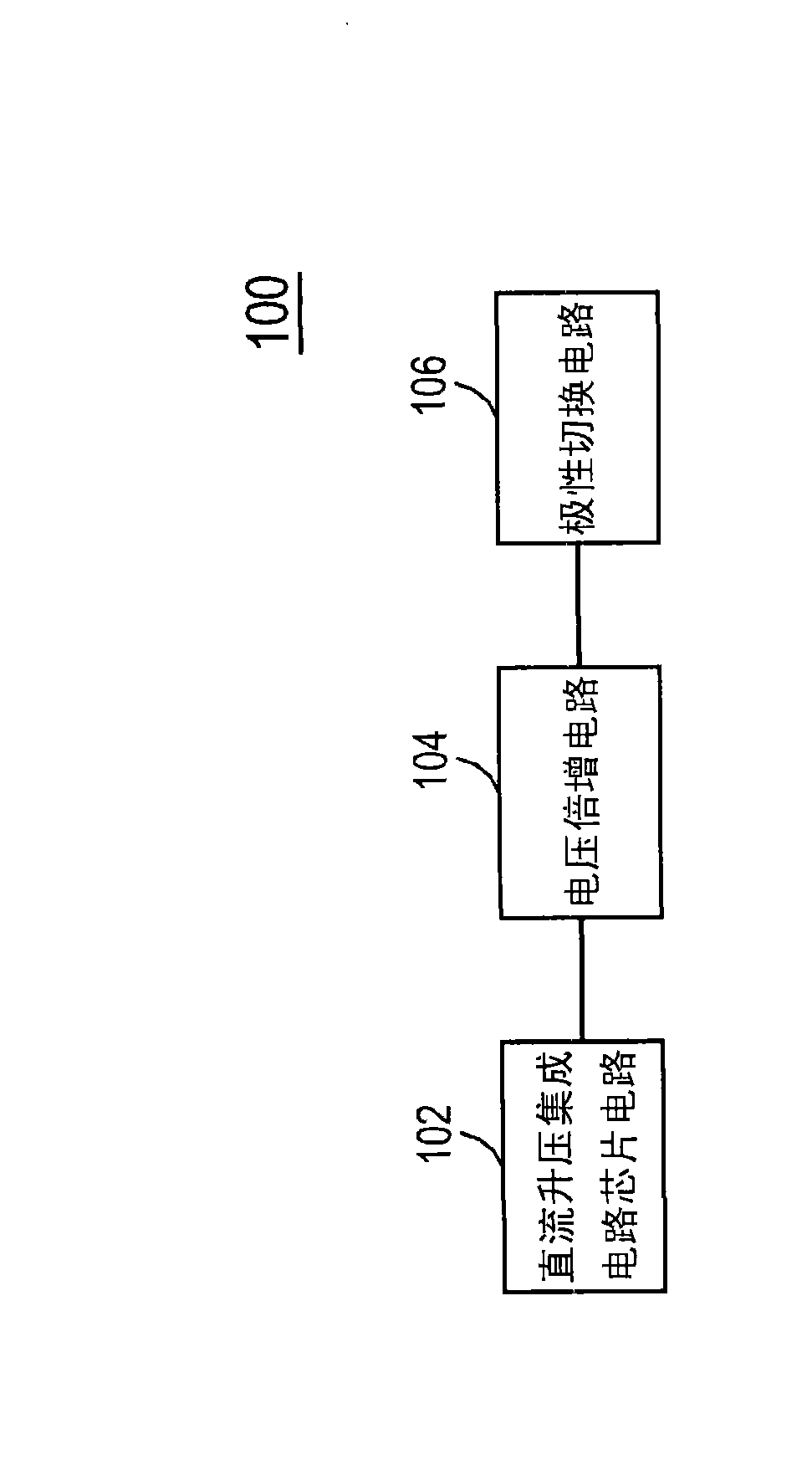

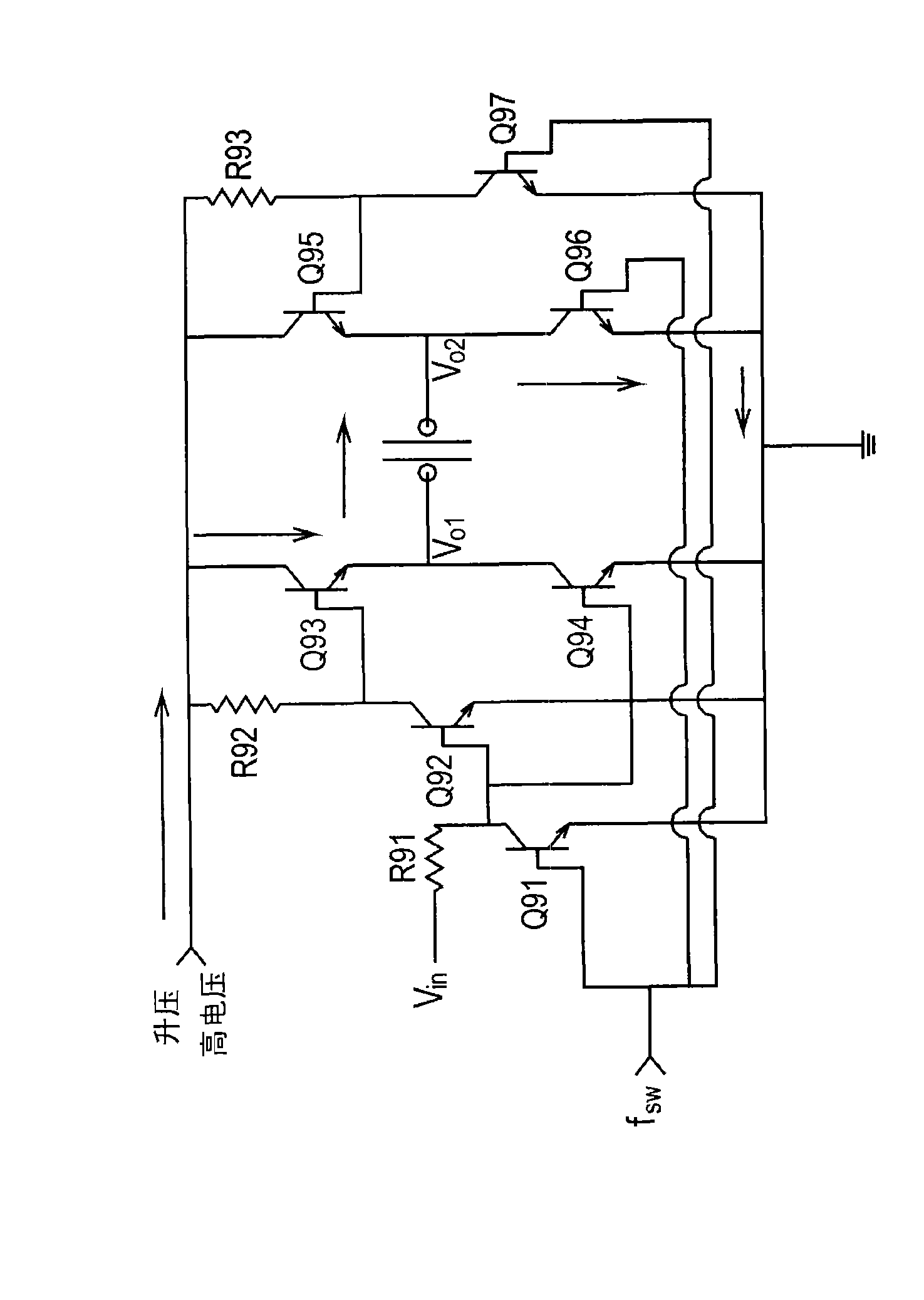

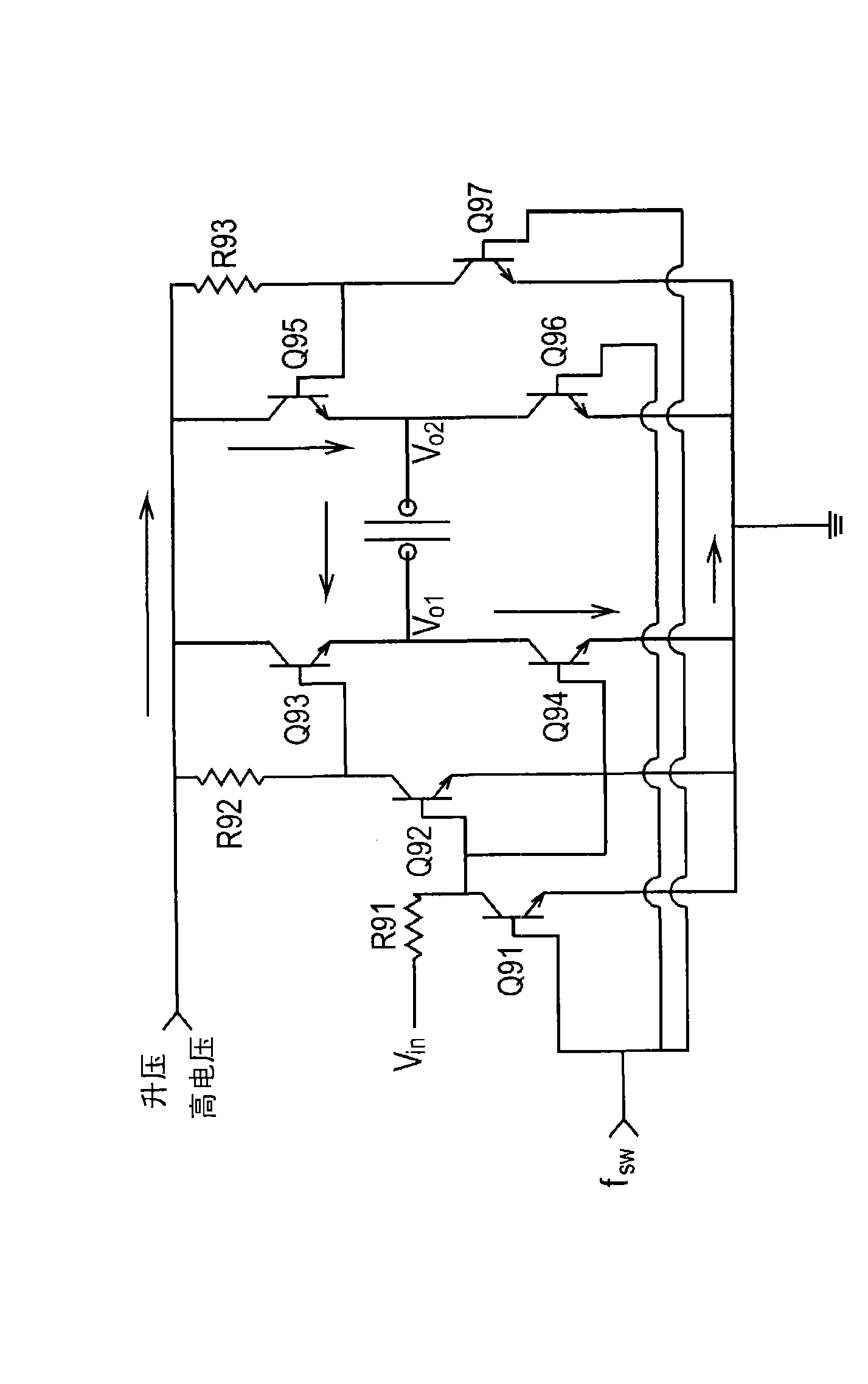

[0046] see Figure 3A , which is a structural schematic diagram of a piezoelectric actuated pump in a preferred embodiment of the present invention. As shown in the figure, the piezoelectric actuated pump 3 of the present invention is mainly composed of a mechanism body 301 and a drive circuit 300. The drive circuit 300 and the mechanism The main body 301 is connected to mainly use the electric driving circuit 300 to receive an input DC low voltage and convert it into output AC voltages Vo1 and Vo2 to drive the mechanism main body 301 to operate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com