Pulping process for commercial soybean milk machine

A soymilk maker and commercial technology, applied in the field of pulping of soymilk maker, can solve the problems of time-consuming, protein denaturation, poor filtering effect, etc., and achieve the effects of saving a lot of time, reducing labor intensity, and improving pulping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

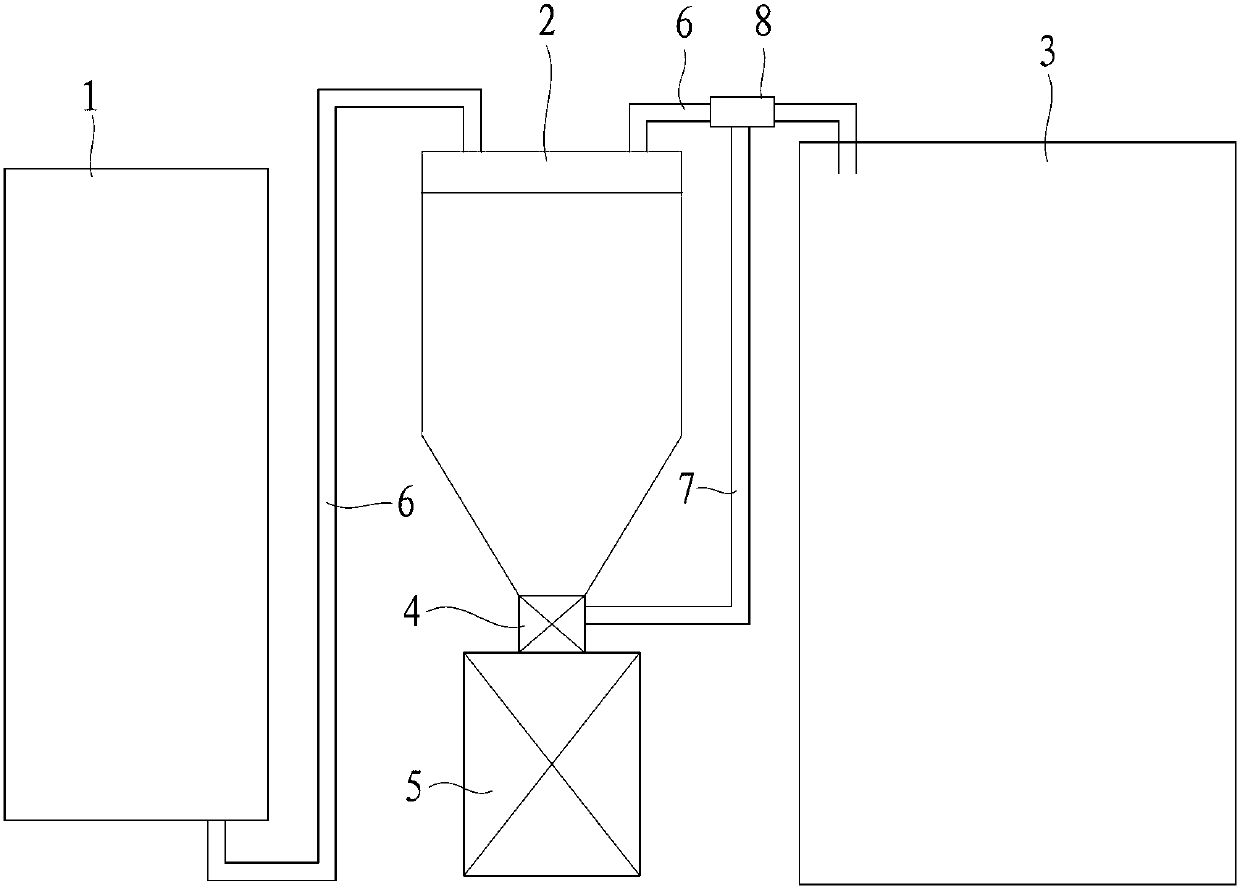

[0031] refer to figure 1 , the pulping method of a commercial soymilk machine in this embodiment, wherein the commercial soymilk machine includes a water tank 1, a hopper 2, a refining component 4, a pulp bucket 3 and a motor 5 that drives the refining component 4, specifically: the refining component 4 is set At the lower part of the hopper 2, the output shaft of the motor 5 can drive the refining part 4 to rotate forward or reversely, and a water delivery pipe 6 is provided between the water tank 1 and the hopper 2; The pulp pipe 7, and the drain pipe and the pulp discharge pipe are connected to the pulp bucket 3 through a three-way control valve 8.

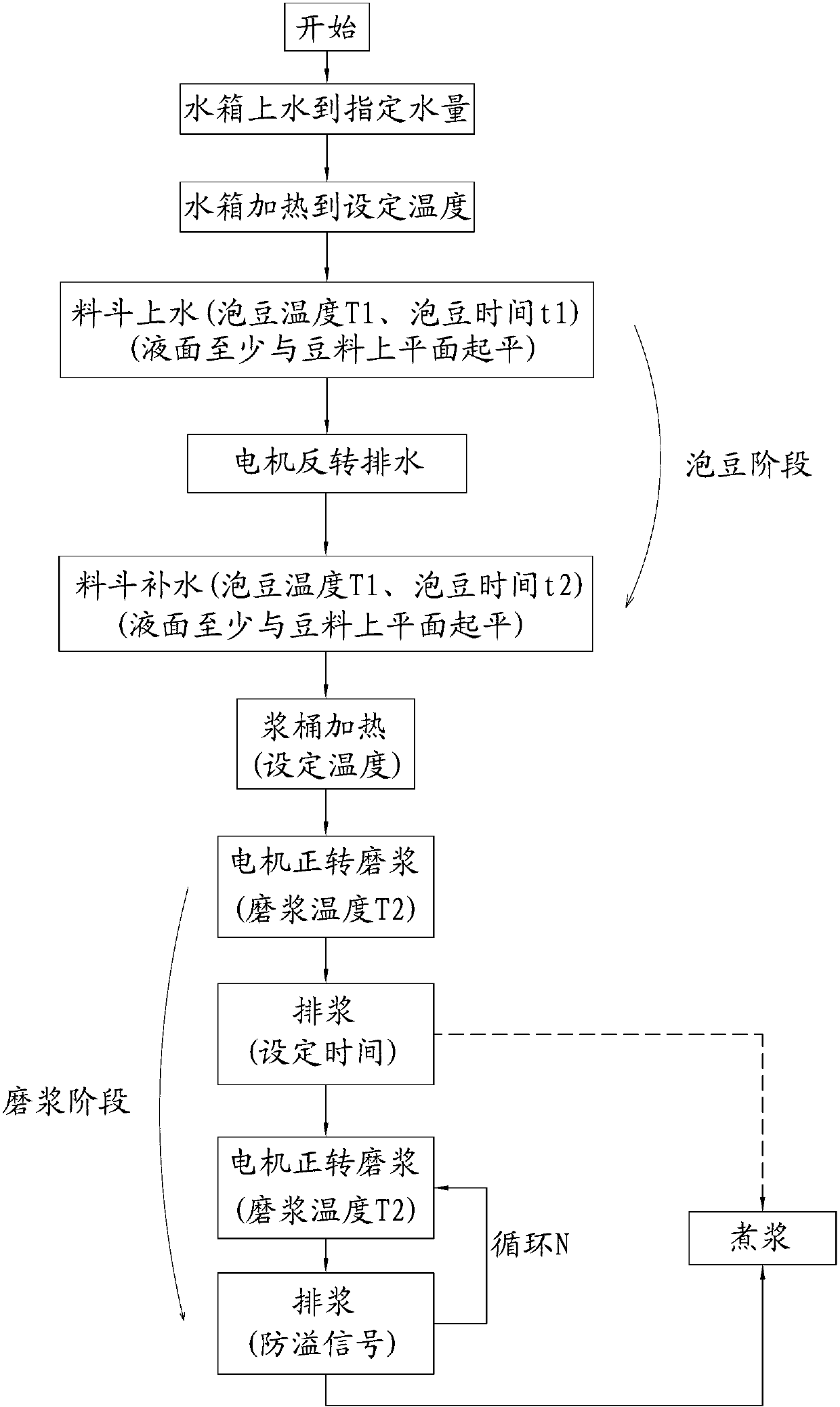

[0032] refer to figure 2 The pulping method using the commercial soybean milk machine of this embodiment includes the following stages (this embodiment takes dry soybean pulp as an example):

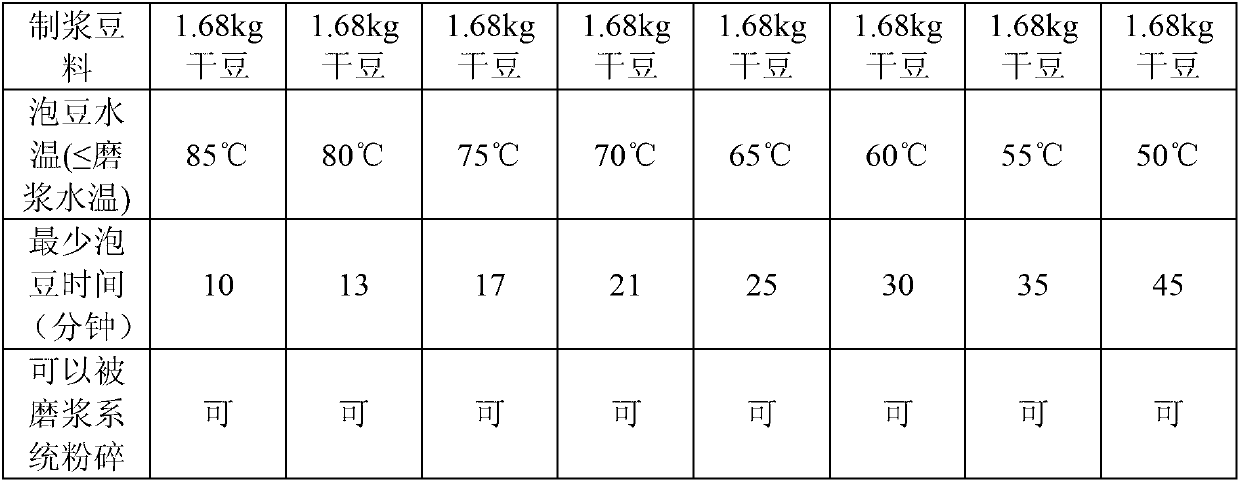

[0033] a. In the bean soaking stage, the water tank 1 is heated to the set temperature and then drains water into the hopper 2, and t...

Embodiment 2

[0060] The bean material for pulping in this example uses peeled beans. Considering the filtering effect, the bottom of the pulp tank, the pulverization performance, the concentration and the quality of soy milk, the water temperature of the soaked beans for pulping with peeled beans is set at 51°C-55°C , soaking time is 20 minutes. The specific implementation method will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com