Wood product preservative

A technology for preservatives and wood products, applied in the direction of wood impregnation, wood impregnation, manufacturing tools, etc., can solve problems such as toxicity and unfavorable environmental protection, and achieve the effects of preventing precipitation, moderate price and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

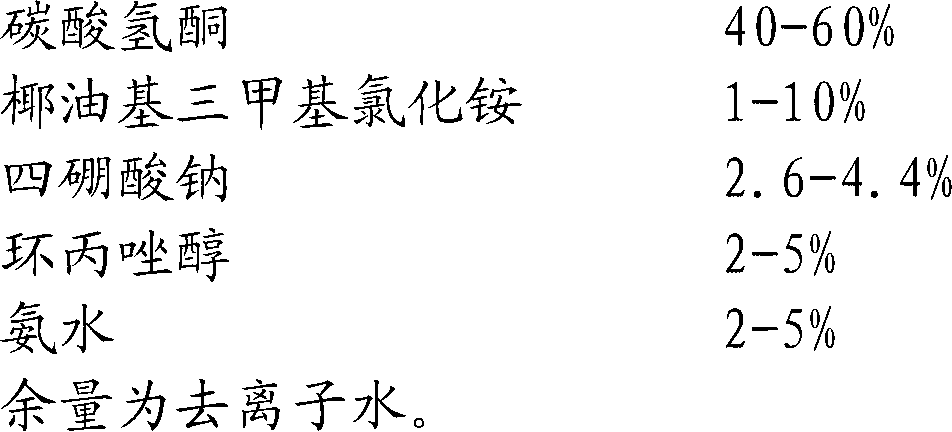

[0013] The wood product preservative of the present embodiment is made up of the following components by weight percentage

[0014]

[0015] The preparation method of the wood preservative of the present embodiment may further comprise the steps:

[0016] (1) Mix 1% cocotrimethylammonium chloride, 2.6% sodium tetraborate, 2% cyproconazole and a small amount of deionized water, heat the mixture to 100-110°C, and keep stirring until the tetraboric acid Sodium dissolves completely;

[0017] (2) After cooling to room temperature, add 40% bicarbonate and 2% ammonia water, and finally add deionized water to make the total weight percentage 100%;

[0018] (3) Stir until all components are completely dissolved.

Embodiment 2

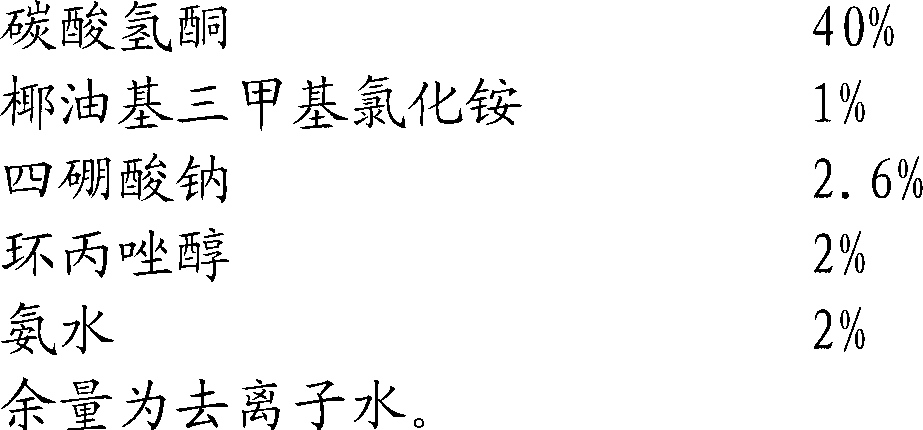

[0020] The wood product preservative of the present embodiment is made up of the component of following percentage by weight:

[0021]

[0022] The preparation method of the wood preservative of the present embodiment may further comprise the steps:

[0023] (1) Mix 3% cocotrimethylammonium chloride, 3.0% sodium tetraborate, 3.6% cyproconazole and a small amount of deionized water, heat the mixture to 100-110°C, and keep stirring until the tetraboric acid Sodium dissolves completely;

[0024] (2) After cooling to room temperature, add 46% bicarbonate and 3.5% ammonia water, and finally add deionized water to make the total weight percentage 100%;

[0025] (3) Stir until all components are completely dissolved.

Embodiment 3

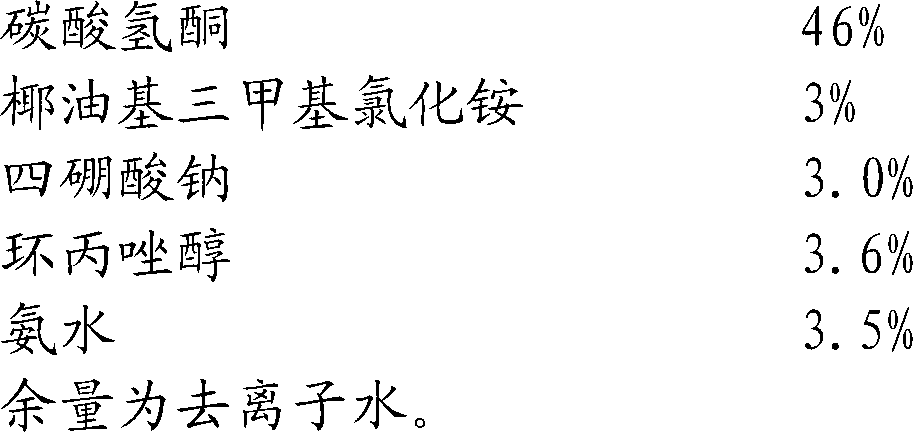

[0027] The wood product preservative of the present embodiment is made up of the following components by weight percentage

[0028]

[0029] The preparation method of the wood preservative of the present embodiment may further comprise the steps:

[0030] (1) Mix 7% cocotrimethylammonium chloride, 3.9% sodium tetraborate, 4.2% cyproconazole and a small amount of deionized water, heat the mixture to 100-110°C, and keep stirring until the tetraborate Sodium dissolves completely;

[0031] (2) After cooling to room temperature, add 52% bicarbonate and 4.3% ammonia water, and finally add deionized water to make the total weight percentage 100%;

[0032] (3) Stir until all components are completely dissolved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Along the grain compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap