Durable shoe polish

A technology of durability and shoe polish, applied in polishing compositions, chemical instruments and methods, etc., can solve problems such as poor durability, and achieve the effects of improved protection, strong dust-proof leather protection, and ideal oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

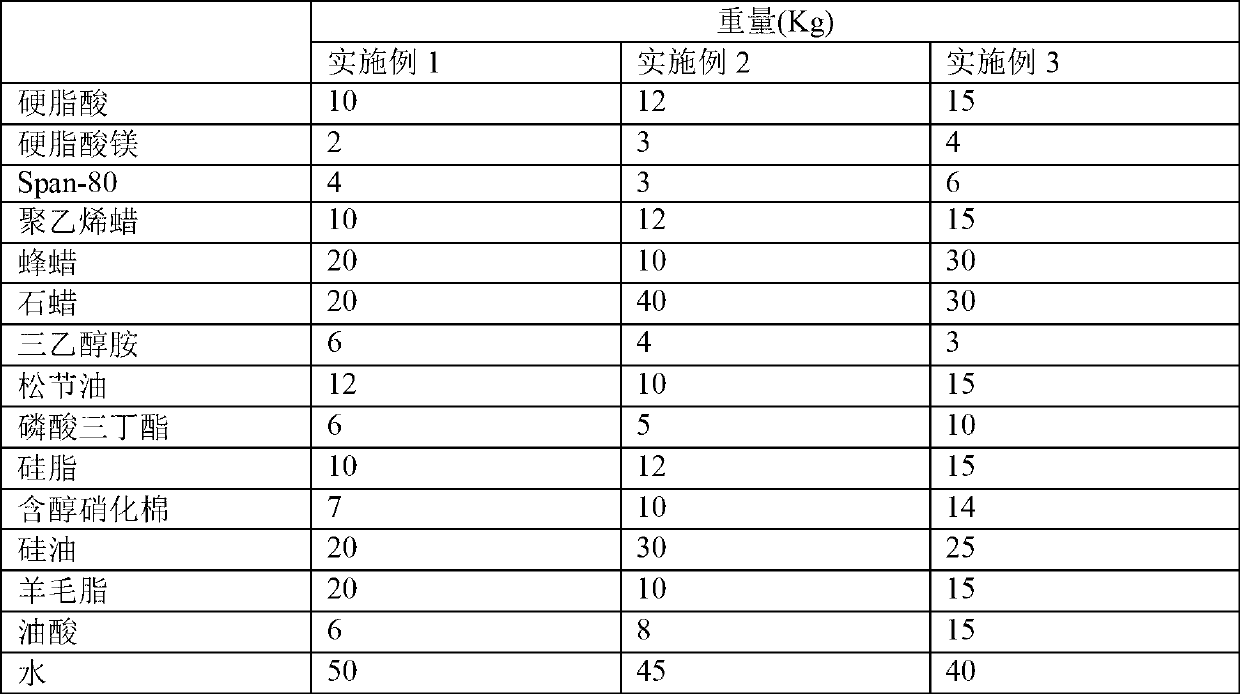

[0014] The components were prepared in the weight ratios shown in Table 1.

[0015] Table 1 The weight ratio of embodiment 1 to embodiment 3

[0016]

[0017] The above-mentioned silicone oil is dimethyl silicone oil.

[0018] The above-mentioned silicone grease is dimethyl silicone grease (Example 1), methylphenyl silicone grease (Example 2) or methyl fluoropropyl silicone grease (Example 3).

[0019] The preparation method is:

[0020] Heat and melt stearic acid, polyethylene wax, beeswax, paraffin, tributyl phosphate, silicone grease, and lanolin at 110-120 °C, and add magnesium stearate, triethanolamine, alcohol-containing nitrocellulose, and silicone oil under stirring conditions. , stir evenly, add turpentine and Span-80, then cool down to 90-100°C, add water (pre-heated to 90-100°C), add oleic acid, stir well, let cool to 40-50°C, pack .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com