Multi-chamber carbon anode

A carbon anode and anode technology, applied in the field of carbon anode and carbon anode for aluminum electrolysis, can solve the problems of broken anode, insufficient strength, anode bubble pressure drop, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

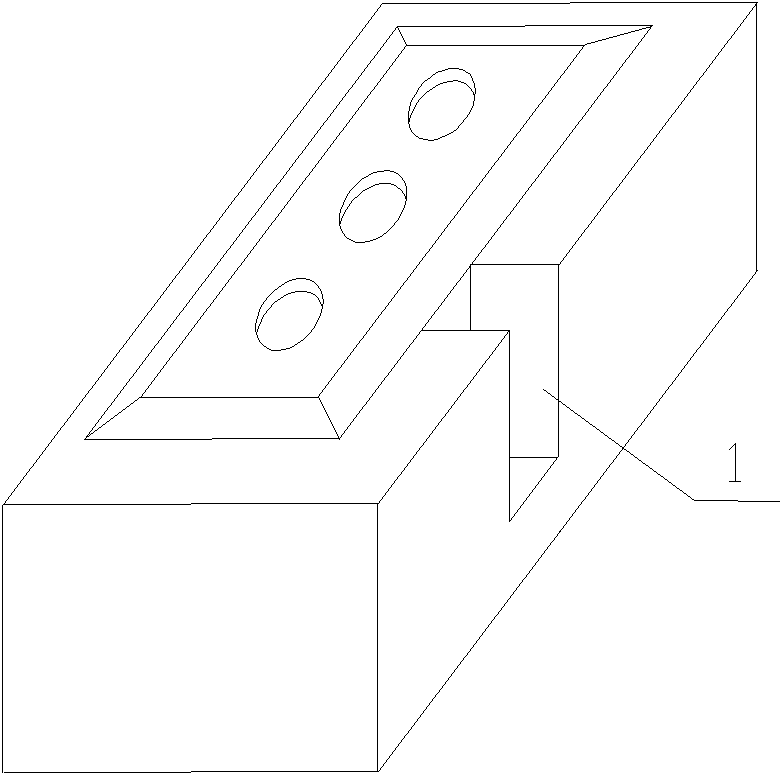

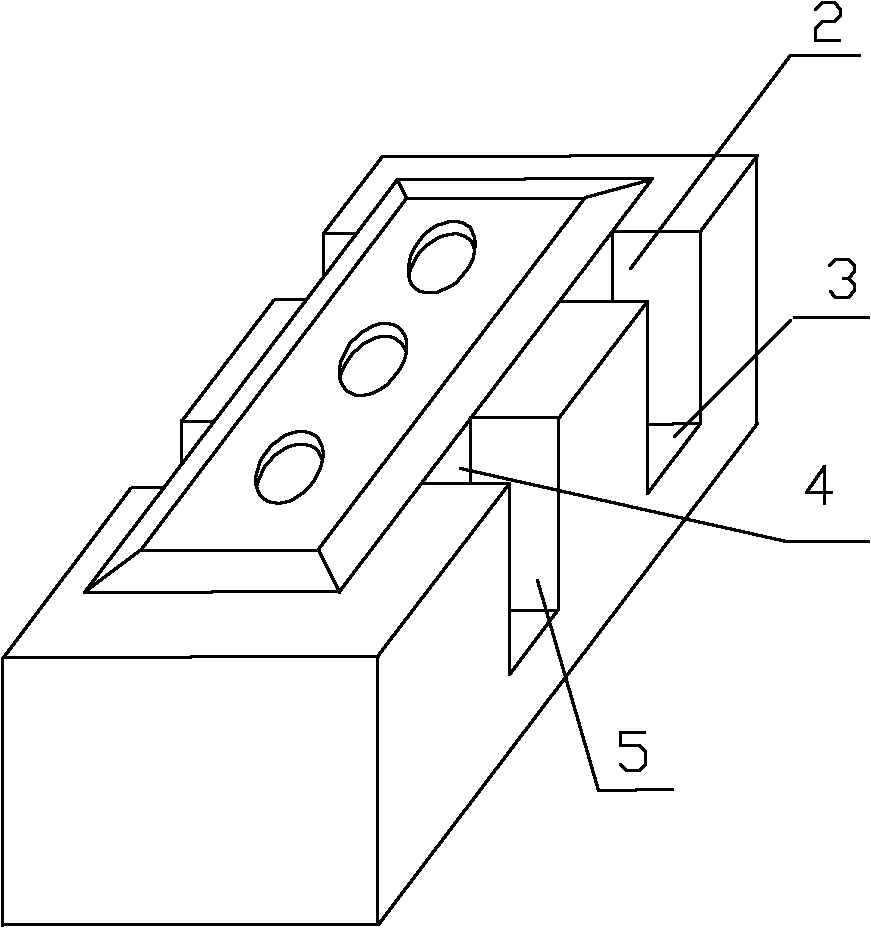

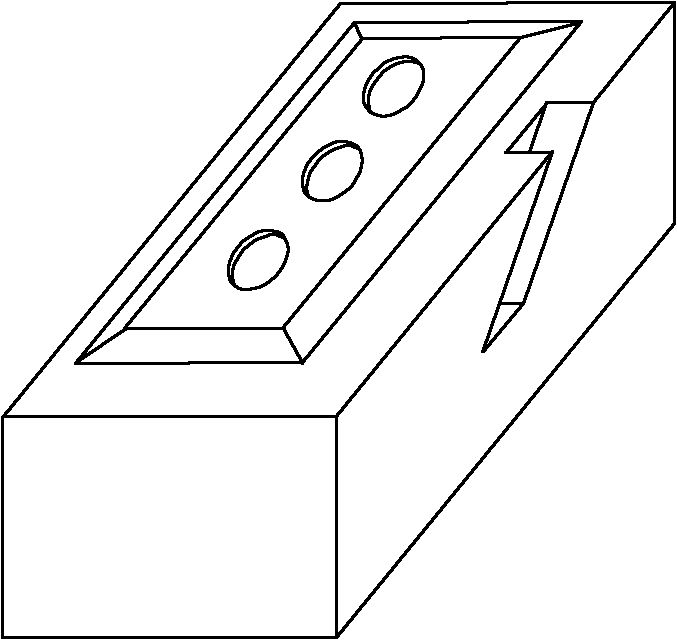

[0023] Such as figure 1 As shown, a multi-chamber carbon anode includes two sides, each of which includes two longest ribs, and is perpendicular to the bottom surface of the anode, and there is a vertical non-through groove 1 on the side of the anode, consisting of Each surface of the groove can be flat or curved. This groove can also be located on the other side parallel to this side. No matter which side the groove can be located at any position on the side of the anode, but the best position is located in the middle area of the side of the anode, the minimum distance from the left edge of the middle area to the left end of the anode is 1 / 10 of the length of the anode , the minimum distance from the right edge to the right end of the anode is 1 / 10 of the anode length. In order to ensure unobstructed exhaust and anode strength more effectively, the groove can be made as a groove with the upper port 2 wider than the lower port 3, or a groove with the opening 5 wider than t...

Embodiment 2

[0025] Such as figure 1 As shown, a multi-chamber carbon anode includes two sides, each of which includes two longest ribs, and is perpendicular to the bottom surface of the anode, and there is a vertical non-through groove 1 on the side of the anode, consisting of Each surface of the groove can be flat or curved. This groove can also be located on the other side parallel to this side. No matter which side the groove can be located at any position on the side of the anode, but the best position is located in the middle area of the side of the anode, the minimum distance from the left edge of the middle area to the left end of the anode is 1 / 5 of the length of the anode , the minimum distance from the right edge to the right end of the anode is 1 / 10 of the anode length. In order to ensure unobstructed exhaust and anode strength more effectively, the groove can be made as a groove with the upper port 2 wider than the lower port 3, or a groove with the opening 5 wider than th...

Embodiment 3

[0027] Such as figure 1 As shown, a multi-chamber carbon anode includes two sides, each of which includes two longest ribs, and is perpendicular to the bottom surface of the anode, and there is a vertical non-through groove 1 on the side of the anode, consisting of Each surface of the groove can be flat or curved. This groove can also be located on the other side parallel to this side. No matter which side the groove can be located at any position on the side of the anode, but the best position is located in the middle area of the side of the anode, the minimum distance from the left edge of the middle area to the left end of the anode is 1 / 10 of the length of the anode , the minimum distance between the right edge and the right end of the anode is 1 / 5 of the anode length. In order to ensure unobstructed exhaust and anode strength more effectively, the groove can be made as a groove with the upper port 2 wider than the lower port 3, or a groove with the opening 5 wider tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com