Coal seam drilling coal-gas-water separating, conveying and containing device

A technology for coal seam drilling and moisture, which is applied to the device for preliminary separation and inductive transportation of gas and water, and the hydraulic mining of extruded materials for the coal field, achieving the effects of good safety and stability, convenient transportation and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

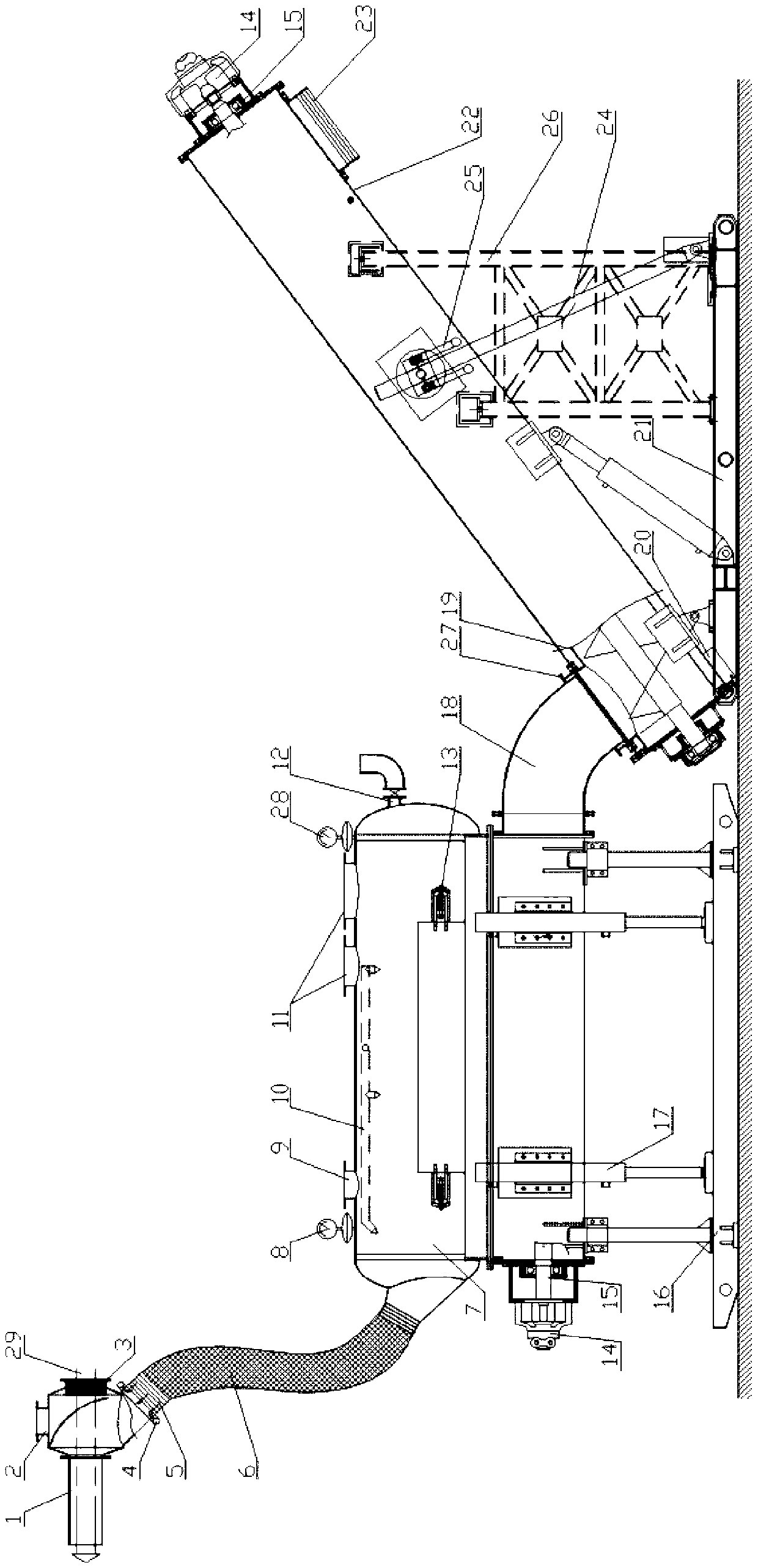

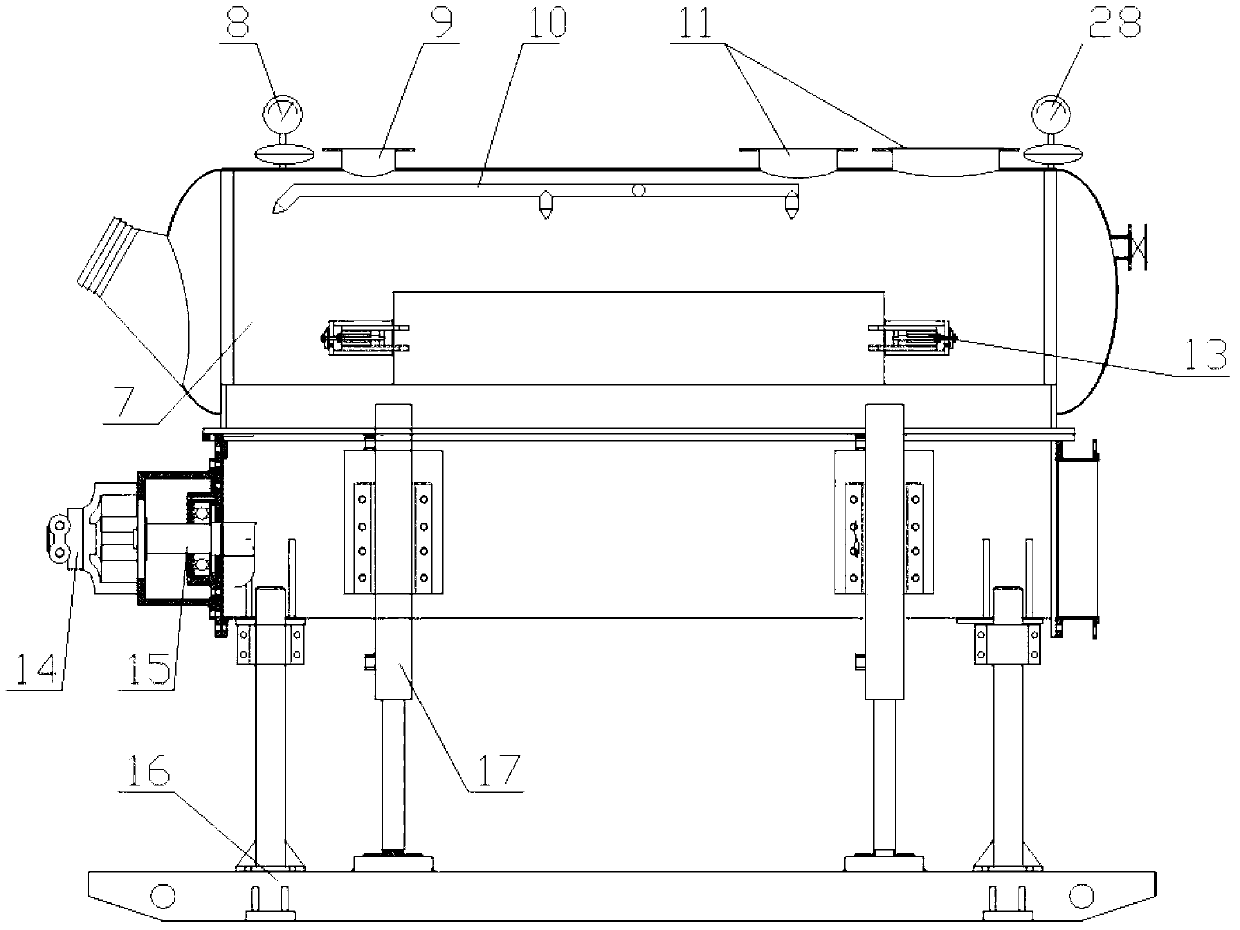

[0033] Such as figure 1 As shown, the coal seam drilling and mining coal, gas and water separation and transportation device includes a dynamic and static combination sealed quick-loading collector, a coal and gas separation conveyor, and a coal and water separator;

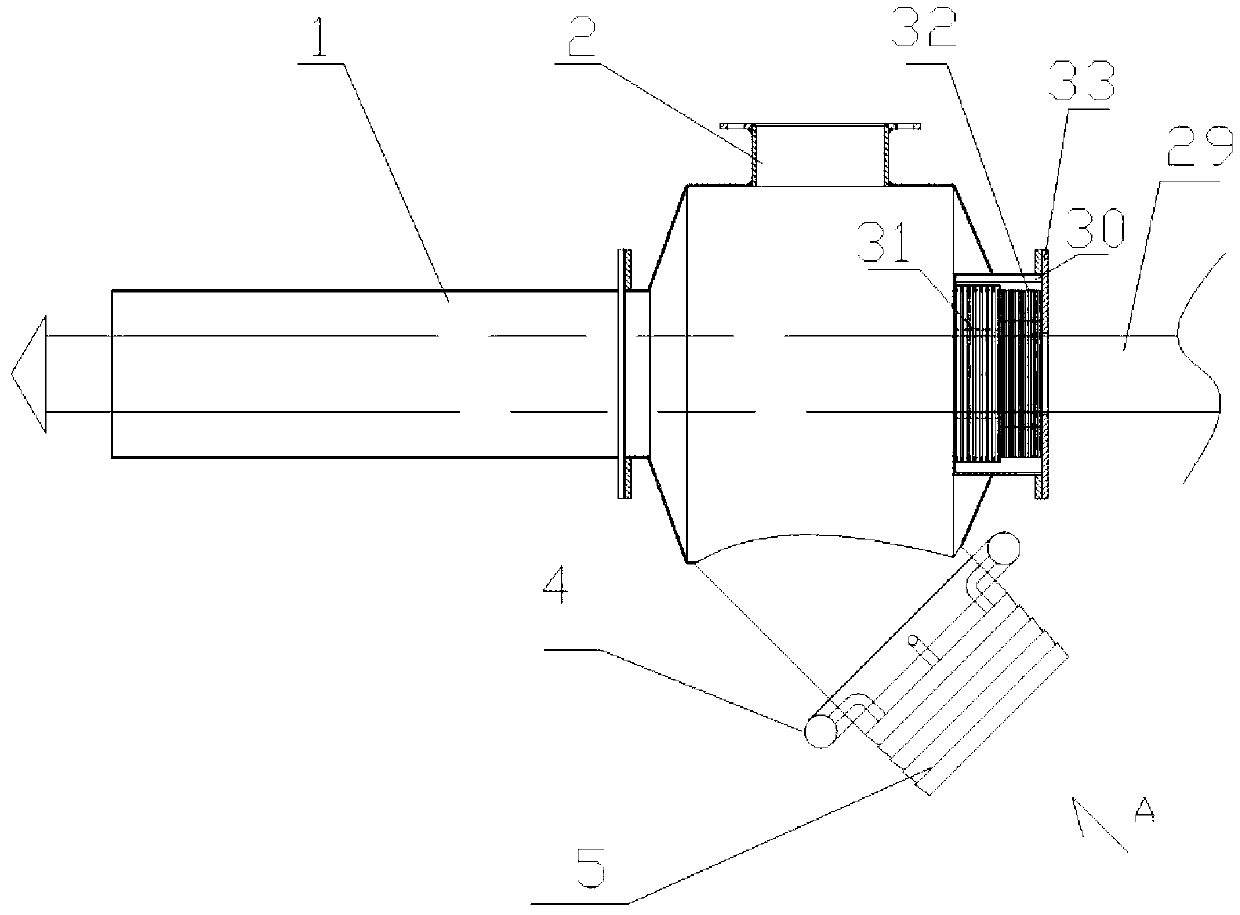

[0034] Such as figure 2 As shown, the static and dynamic combination sealed quick-loading collector is connected to the tail end of the borehole pipe 1, and the collector is provided with a gas pumping outlet 2, a coal and gas delivery port 5, and a drill port corresponding to the axial direction of the borehole pipe. , the drill port is provided with a dynamic and static sealing structure 3 that forms a seal with the drill pipe; the dynamic and static sealing structure 3 is sequentially composed of a static seal 31 and a dynamic seal 32 from the inside to the outside; Figure 6 As shown, the main body of the static seal is composed of a helical ring 31a arranged in the axial direction of the drill pipe. The ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com