Coal shearer spray range adjustable inner spray device

A technology of internal spraying and shearer, applied in the direction of slitting machinery, earth square drilling, etc., can solve the problems of small spray water pressure and water volume, large amount of dust in coal mining work, waste of water resources, etc., and increase water flow and pressure head, improve the effect of dust suppression, and reduce the effect of nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

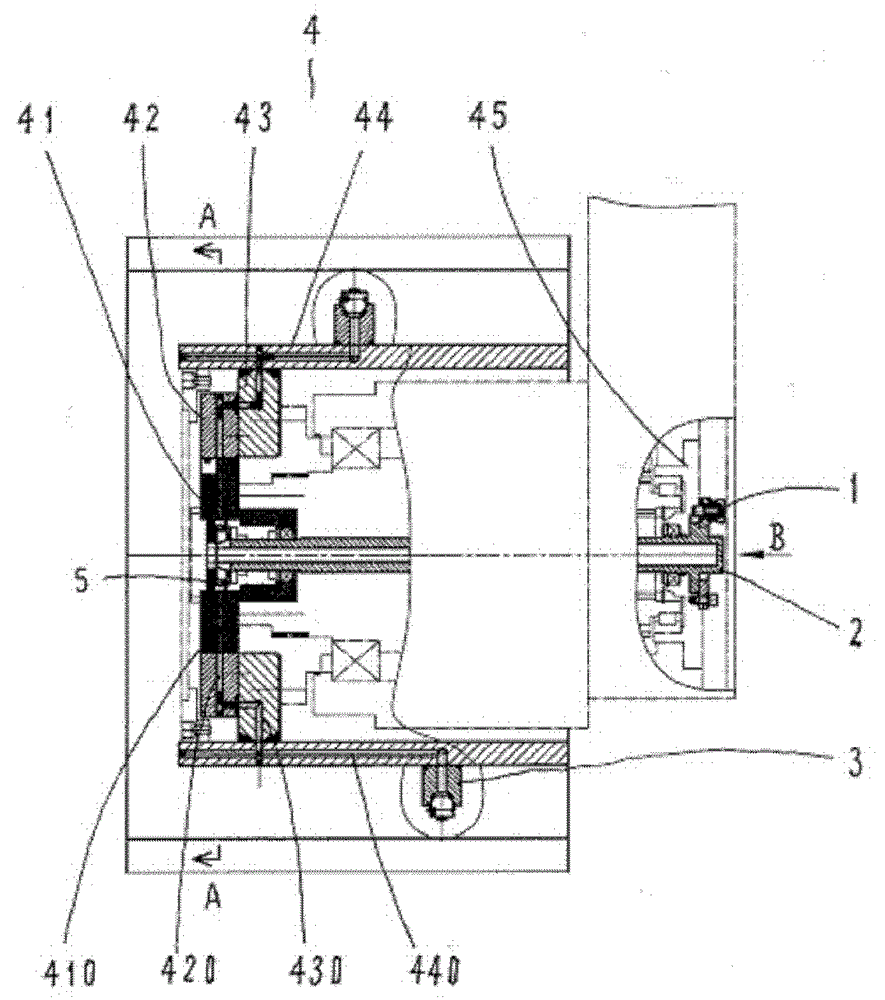

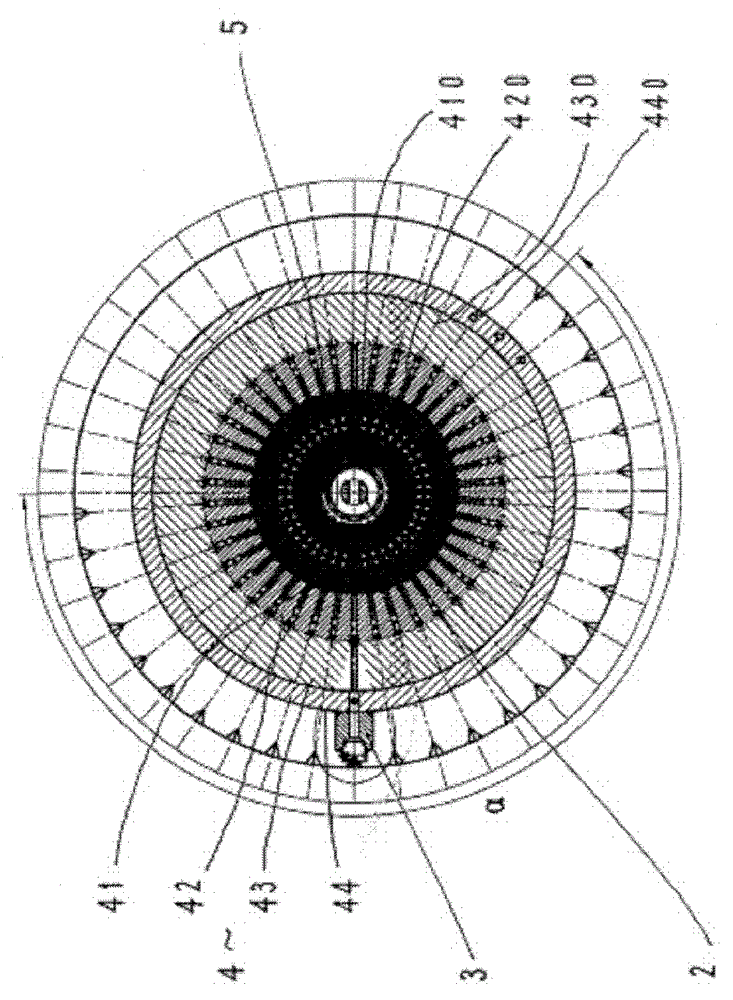

[0017] refer to figure 1 , 2 The spraying range of the shearer can be adjusted and the spraying device includes a water supply system, a hose, a water pipe joint, a positioning dial assembly 1, a water pipe assembly 2, a nozzle 3, a drum 4 and a water reversing disc 5, a water supply system, a hose and a water pipe The joints are all the same or similar to the prior art.

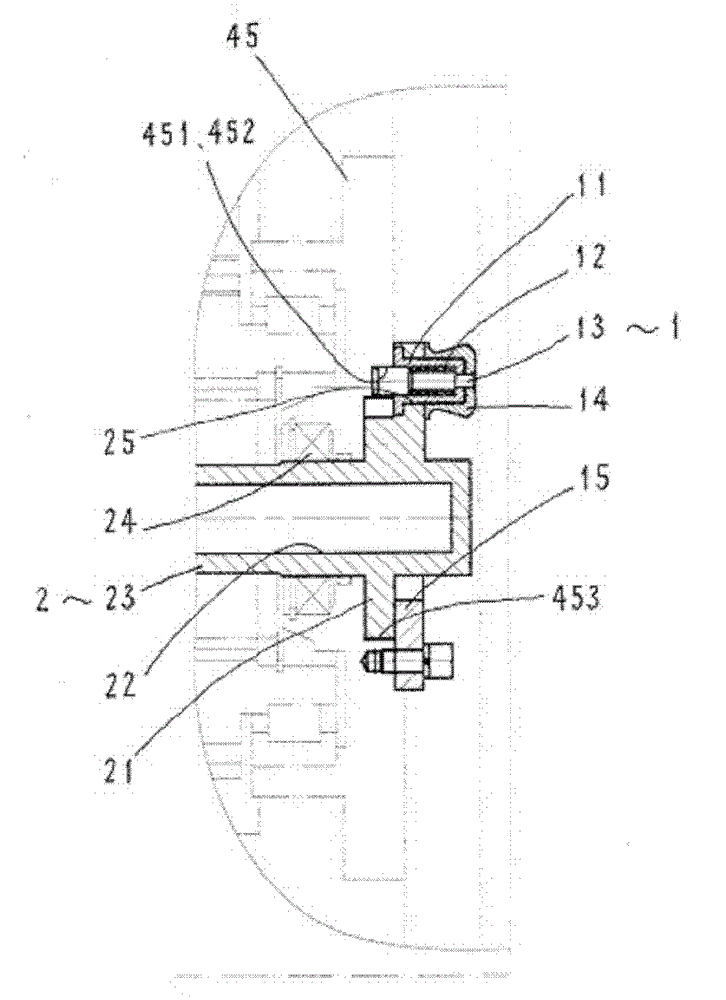

[0018] Locate the button assembly 1, such as image 3 As shown, it is a unique structure of the present invention, including a bushing 11, a spring 12, a positioning pin 13, a positioning dial 14 and a pressure plate 15; wherein:

[0019] The bushing 11 is a sleeve-shaped member, and its outer cylindrical surface can be passed through the bushing hole 25 of the pipe end flange 21 of the water inlet end of the water pipe assembly 2, and the end flange of the bushing 11 is embedded in the bushing hole 25 The pits form the axial positioning of the bushing 11, and the bottom of the bushing 11 has a through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com