Adaptive process control system of condenser for ship and method for implementing adaptive process control system

A technology of process control system and implementation method, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of single control mode, reduce the degree of subcooling of condensate, and long control stability time, and achieve the guarantee Safety, reducing control disturbance and ensuring the effect of control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

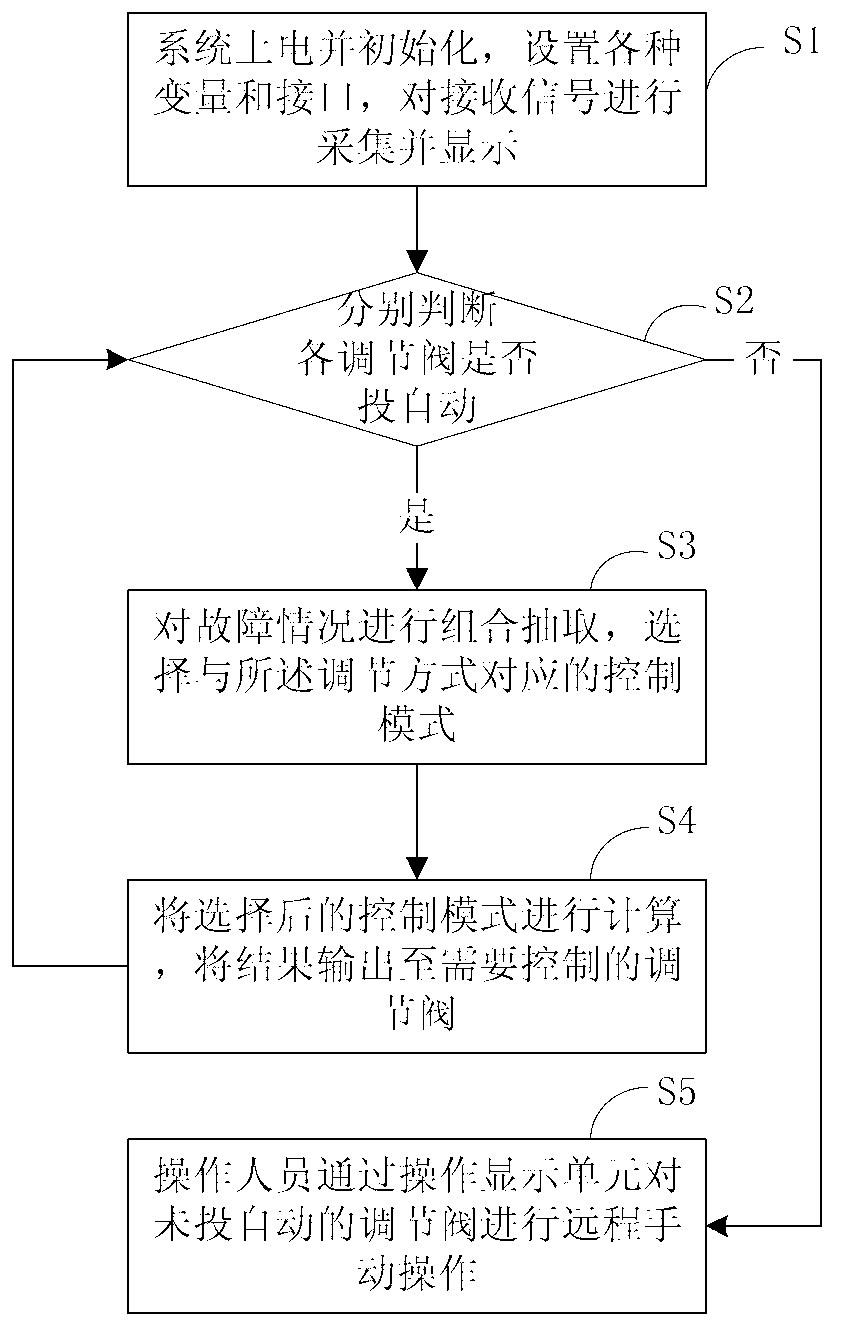

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

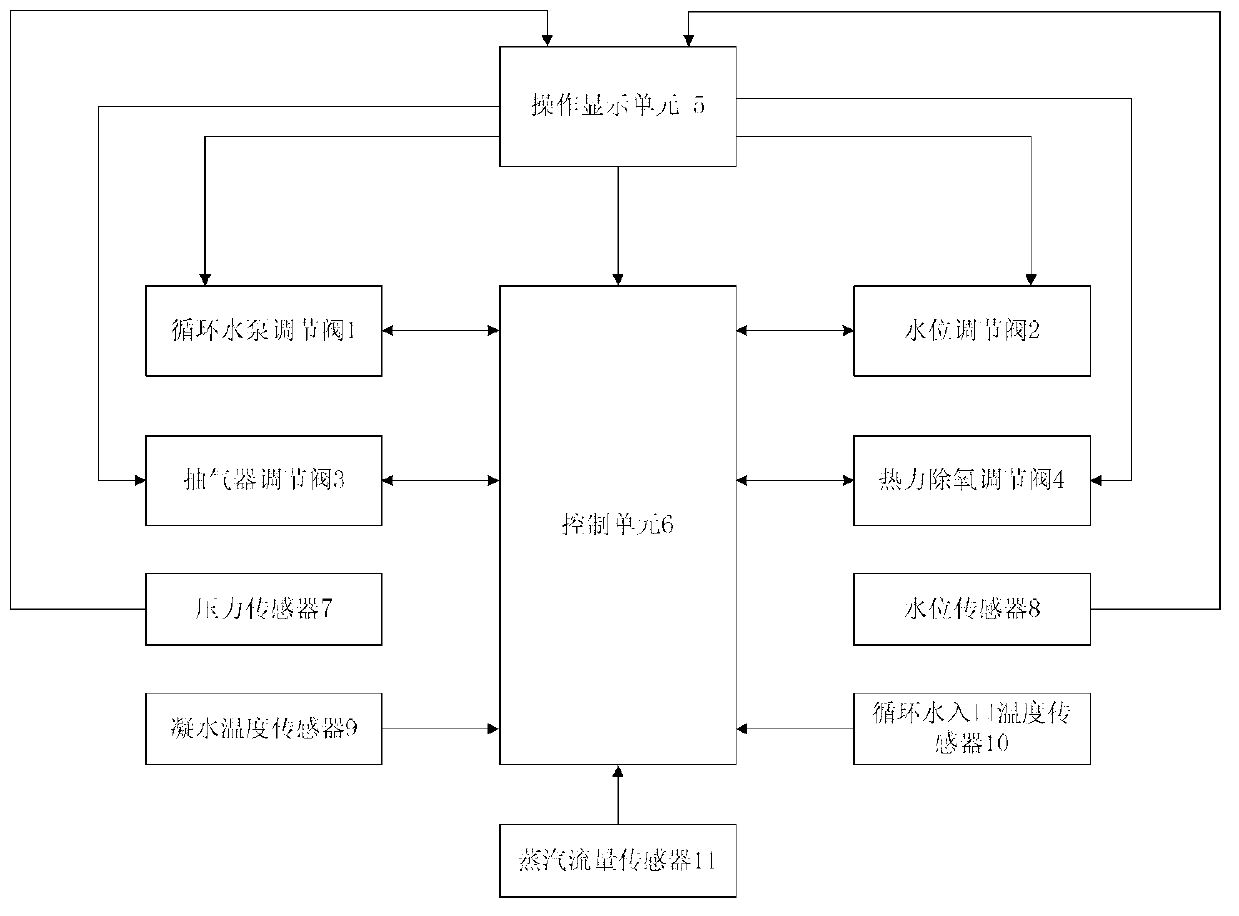

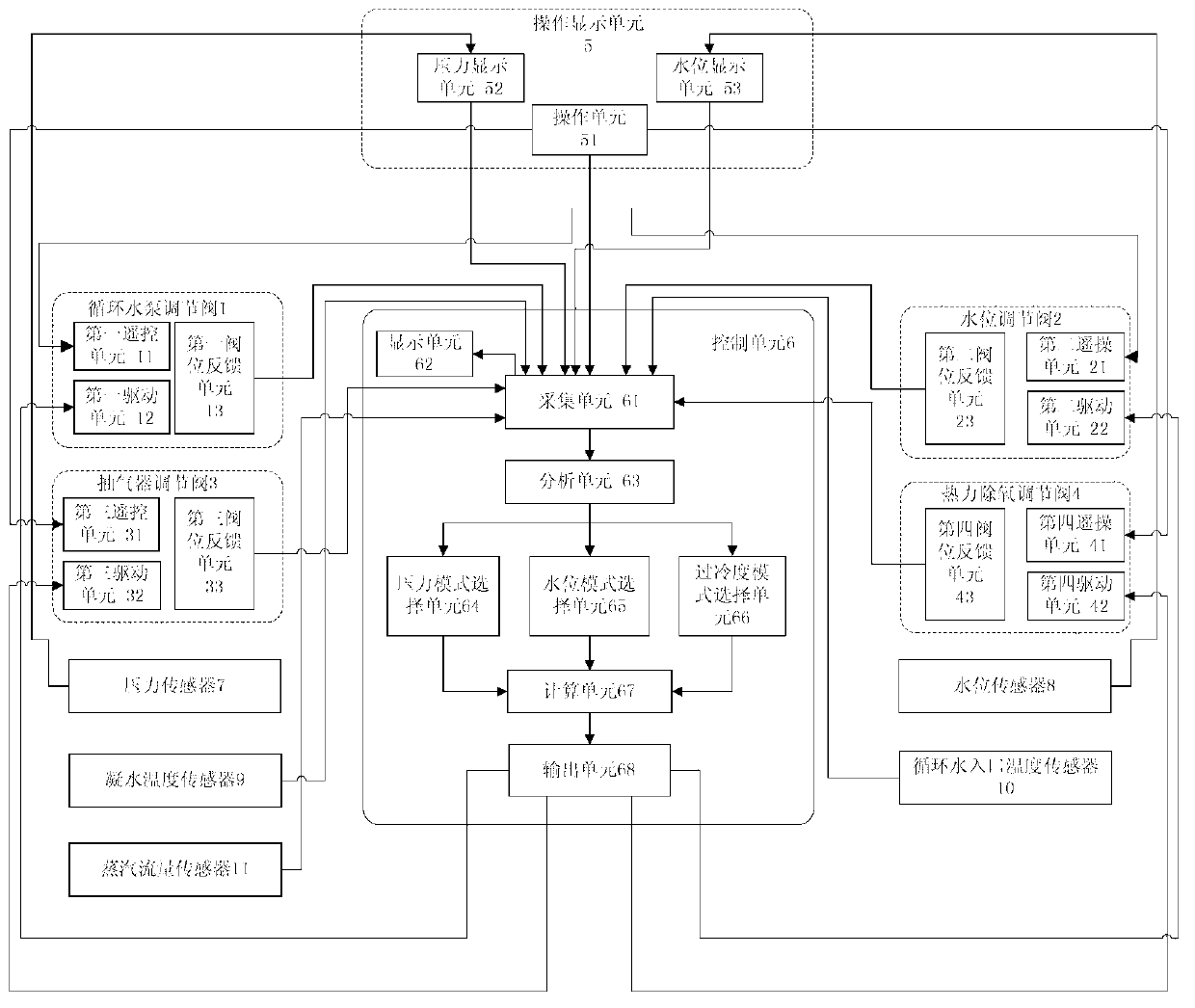

[0040] like figure 1 As shown, the adaptive marine condenser process control system of the present invention includes a control unit 6, an operation display unit 5, a circulating water pump regulating valve 1, a water level regulating valve 2, an air extractor regulating valve 3, a thermal Deaerator regulating valve 4, condensate temperature sensor 9, circulating water inlet temperature sensor 10 and steam flow sensor 11; the circulating water pump regulating valve 1, water level regulating valve 2, air extractor regulating valve 3, thermal deoxidizing regulating valve 4 It is also connected with the operation display unit 5; the operation display unit 5 is also connected with a pressure sensor 7 of a condenser and a water level sensor 8 of a condenser, wherein, the air extractor regulating valve 3 is the steam inlet adjustment of the air extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com