Method for improving mechanical strength of cylindrical voltage regulation coil

A voltage regulating coil and mechanical strength technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of limited screen tightness, large mechanical stress, poor insulation performance and mechanical performance, etc., to achieve binding tightness guarantee , enhance the mechanical strength, improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

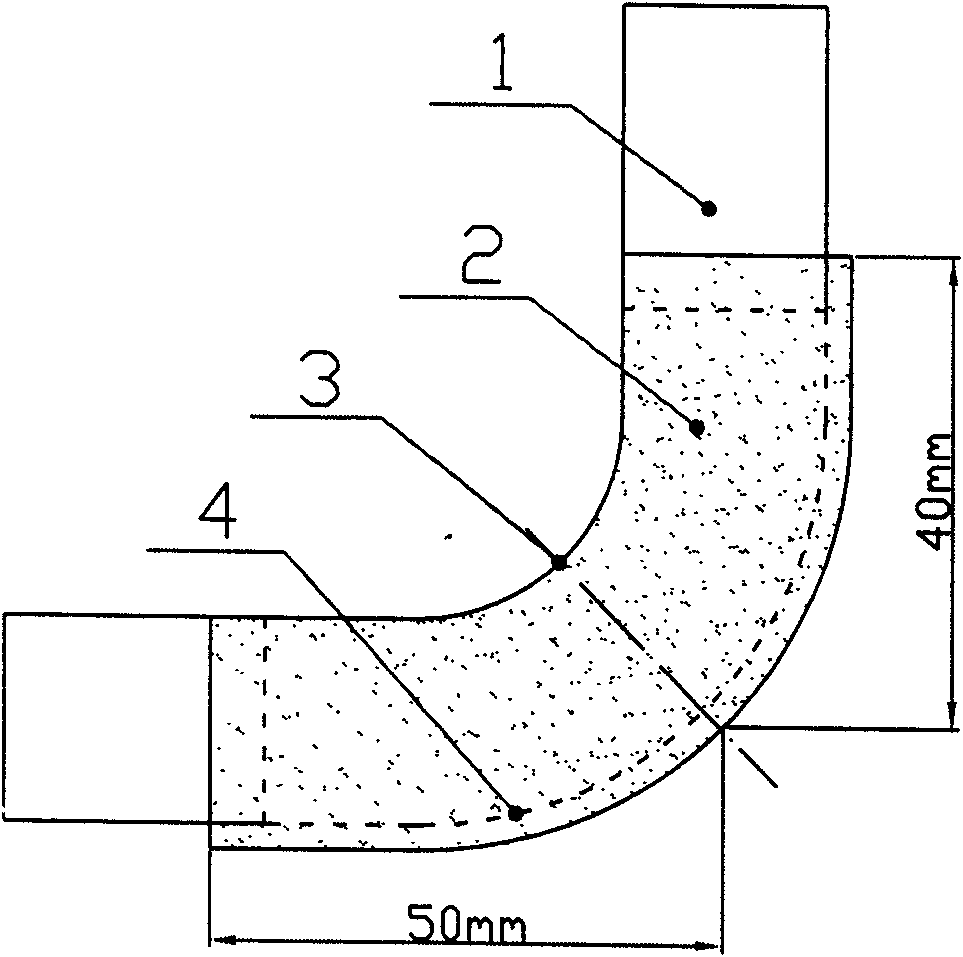

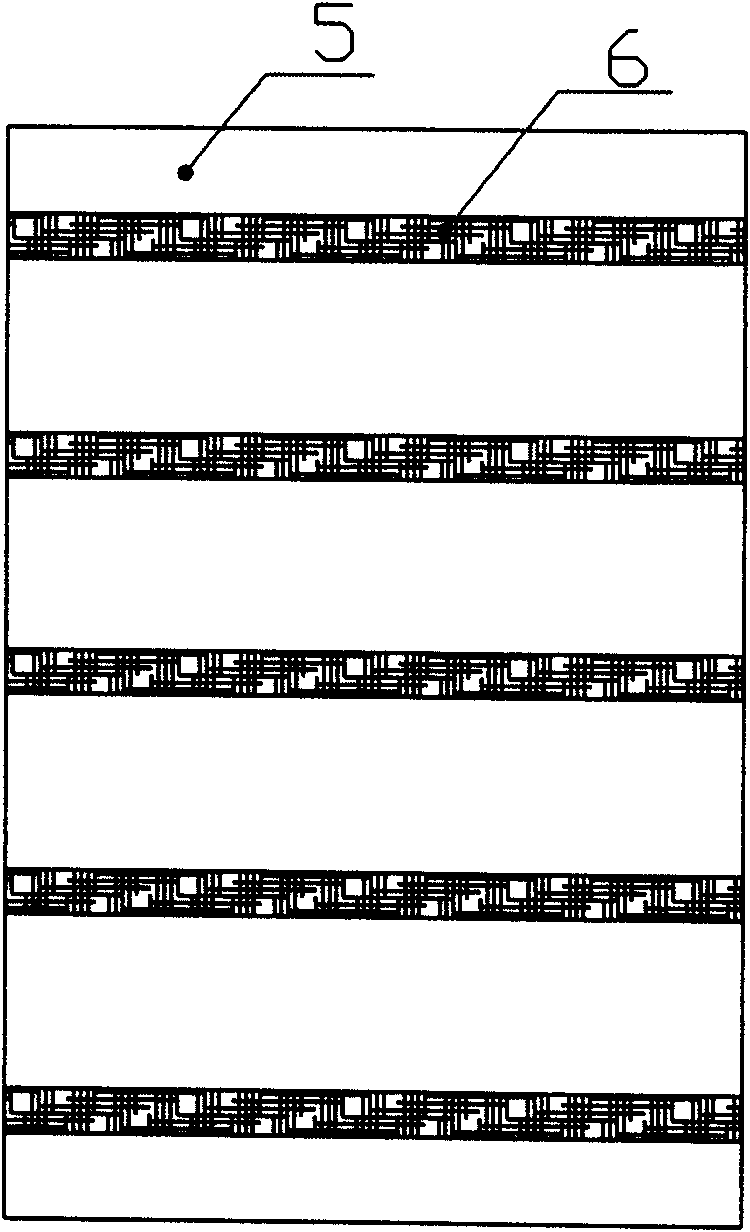

[0009] refer to figure 1 , 2 , first use the shrinkage tape to bind and fix the outlet line cake 1 of the cylindrical voltage regulating coil, then remove the original insulation at the 90° bend of the radial or axial line cake, and then wrap it with Denison insulating paper 2. The original insulation thickness, and then add a paper groove 4 with a thickness of 0.5mm between the 90° bend of the radial or axial line cake and the adjacent turns, and then wrap Denison insulating paper 2 outside the paper groove. The length of wrapping Denison insulating paper 3 inwards at the 90° bend of the radial or axial line cake is 50mm, and the length of wrapping Denison insulating paper outward at the 90° bend of the radial or axial line cake is 40mm. Utilize the PET strapping machine to use the PET strap 6 to carry out final binding to the cylindrical pressure regulating coil screen 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com