Method for manufacturing variable cross section of N-shaped sheathed thermocouple

An armored thermocouple and variable cross-section technology, which is used in the manufacture/processing of thermoelectric devices, wire drawing dies, etc., can solve the problems of inability to meet mass production, low work efficiency of the rotary forging method, etc., to ensure accuracy and reliability. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

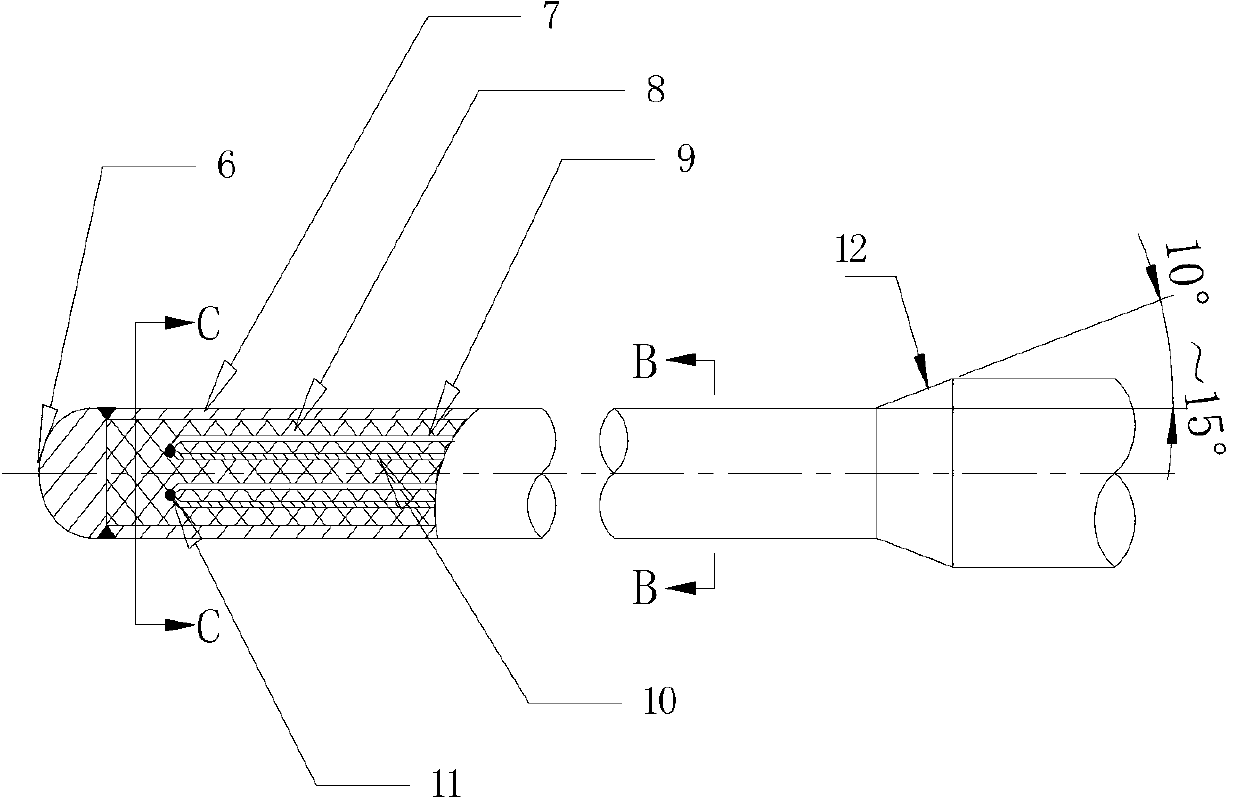

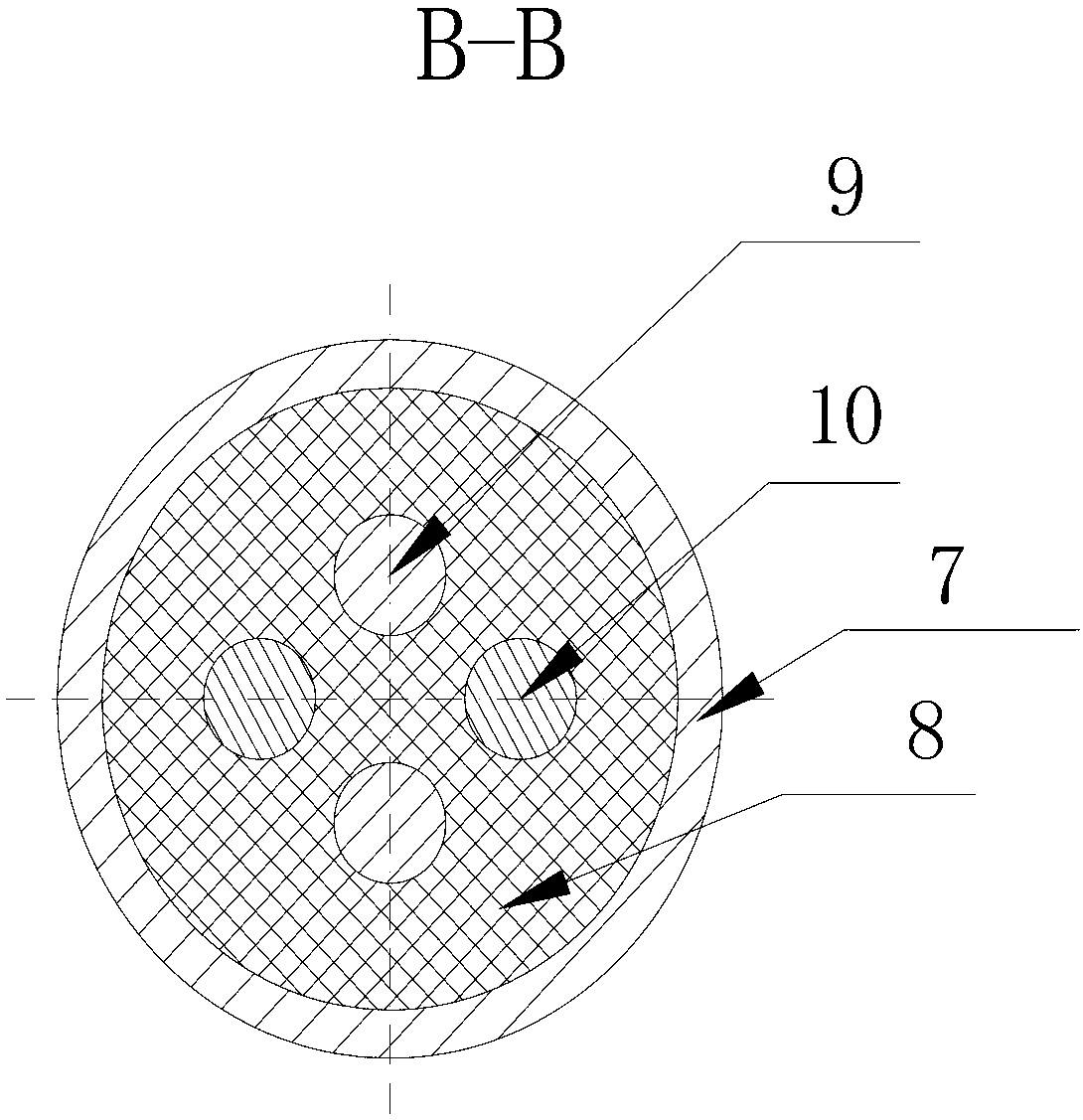

[0031] see Figure 1-Figure 5 :

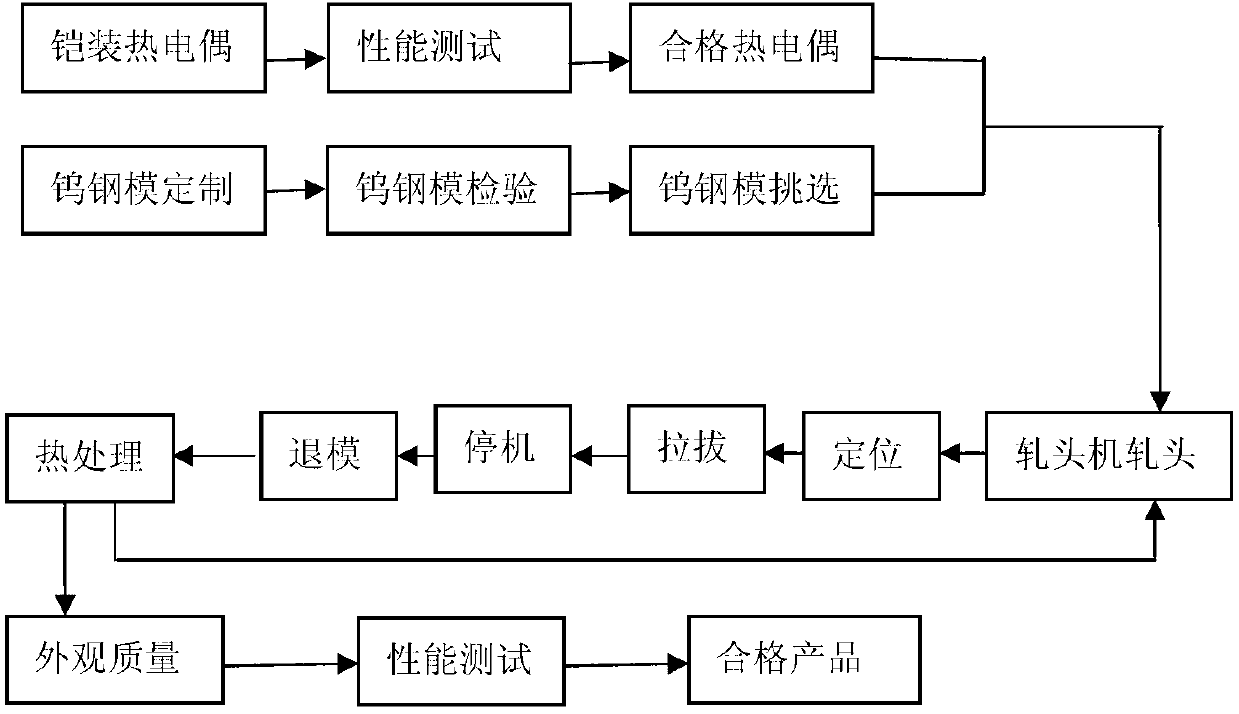

[0032] The preparation method of the N-type (N-type armored thermocouple wire positive pole nickel chromium silicon, negative pole nickel silicon magnesium) armored thermocouple variable cross-section has the following steps:

[0033] 1) Take two nickel-chromium-silicon (positive pole) thermocouple wires 9 and two nickel-silicon-magnesium (negative pole) thermocouple wires 10, straighten and clean them, and then insert them into the insulating porcelain pillars that have been fired at high temperature according to the polarity difference In the process, through shaping, ensure that there is no defect and a gap greater than 10mm between any two adjacent sections of each section of insulating ceramic column that penetrates the pair of wires. Then the insulated porcelain column that has been adjusted and worn with even wires is inserted into the metal tube 7 that has been scrubbed clean. The metal tube of the present invention is a stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com