Method for improving content of potassium in tobacco leaf

A technology of potassium content and tobacco leaves, applied in the field of increasing the potassium content of tobacco leaves, can solve the problems of insignificant increase of the potassium content of tobacco leaves, poor application effect, slow fertilizer effect, etc., and achieves the effects of suitable coordination of chemical composition content, convenient operation, and improved food quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Taking the flue-cured tobacco variety Yunyan 87 as the implementation object, the upper tobacco leaves with stems were harvested, woven into stems, and left to stand for 6 hours, and then a groove was dug at the top of the inverted tobacco stem, and potassium ion concentration of 1mol / L was injected into the groove. Potassium sulfate solution 2 times, inject 6ml each time, let stand for 2 hours after each injection, and finally hang it into the baking room for baking.

[0015] The purpose of standing for 6 hours is to fully wilt the leaves, that is, when the tobacco leaves are placed in dry air, the water in them will gradually lose into the air, which will make the osmotic pressure of the water in the leaves much higher than the osmotic pressure of the flue-cured tobacco stems , laying the foundation for the next transfer of potassium ions and water. Among them, the standard for harvesting the upper tobacco leaves with stems is that the main veins of the upper leaves a...

Embodiment 2

[0020] A method for increasing the potassium content of tobacco leaves. The upper part of flue-cured tobacco leaves with stems are harvested, woven into stems, left to stand for 8 hours, and then a groove is dug at the top of the inverted tobacco stem, and the concentration of potassium ions is injected into the groove at a concentration of 1.4mol / L of potassium carbonate solution 1 time, inject 6ml, let it stand for 4 hours after injection, and finally hang it into the baking room for baking.

Embodiment 3

[0022] A method for increasing the potassium content of flue-cured tobacco. The upper part of flue-cured tobacco leaves with stems are harvested, woven into stems, left to stand for 4 hours, and then a groove is dug at the top of the inverted tobacco stem, and the concentration of potassium ions is injected into the groove at a concentration of 0.8mol / L of potassium dihydrogen phosphate solution 4 times, inject 4ml each time, let it stand for 2 hours after each injection, and finally hang it into the baking room for baking.

[0023] Collect 2 kg of cured tobacco leaves of Examples 1-3 respectively as samples for laboratory analysis and sensory evaluation.

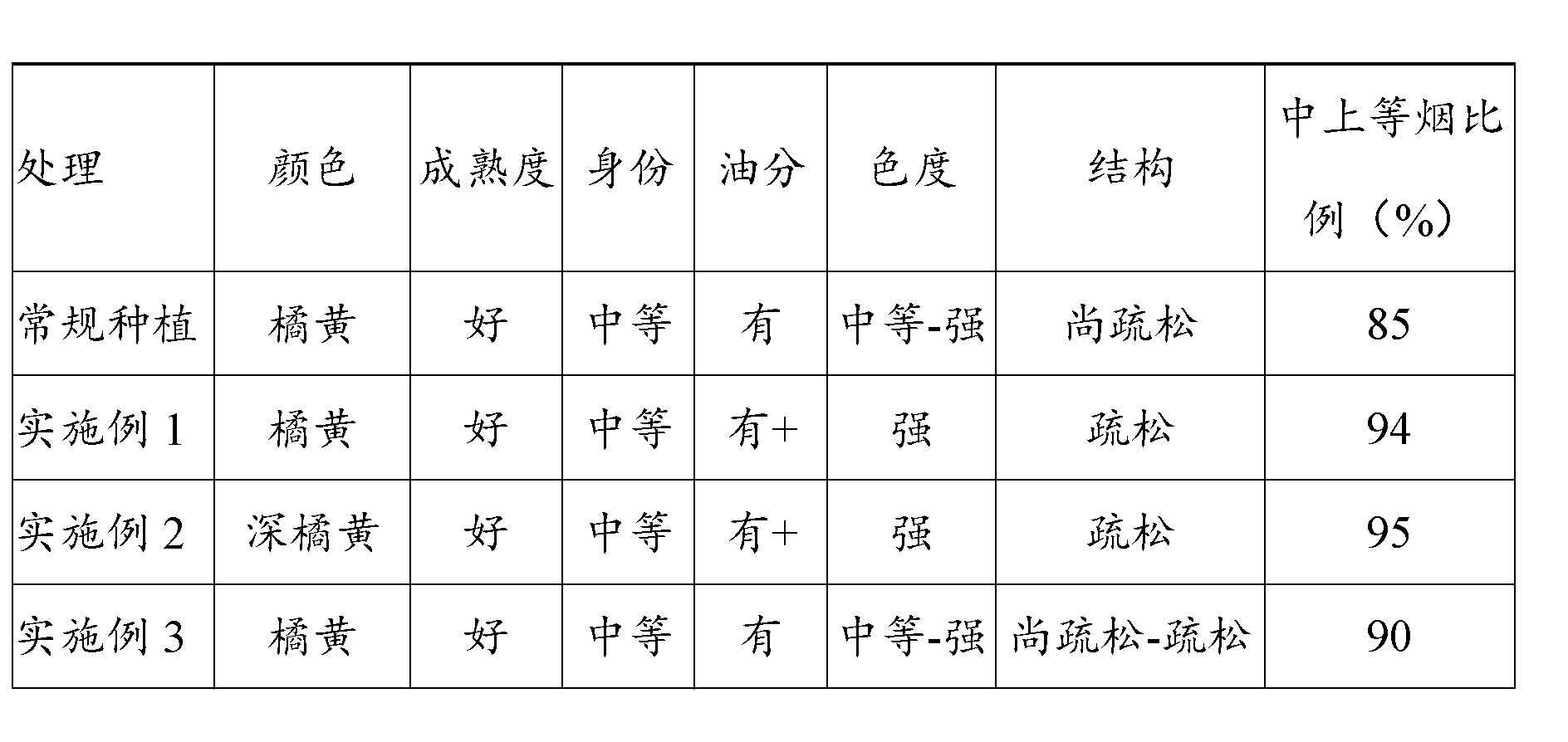

[0024] Quality evaluation of cured tobacco leaves: See Table 1-3 for the results.

[0025] Table 1 Comparison of chemical components between the present invention and untreated B2F grade tobacco leaves (%)

[0026] deal with

[0027] Table 2 Comparison of appearance quality between the present invention and unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com