Air valve mechanism of carbon arc gouging gun

A technology of carbon arc gouging and air valve, which is applied in the direction of lift valve, sliding valve, valve device, etc., which can solve the problems of insufficient air valve guide area, small air flow, and reduced air flow conduction, so as to ensure product processing Quality, enhance the effect of air conduction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

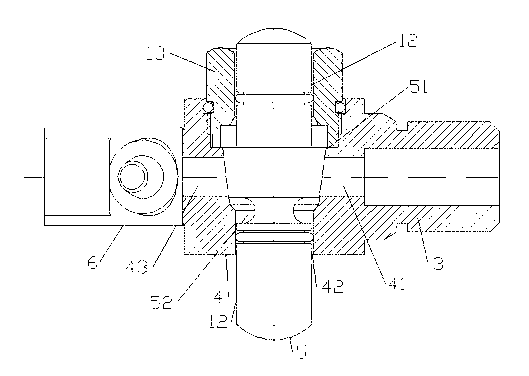

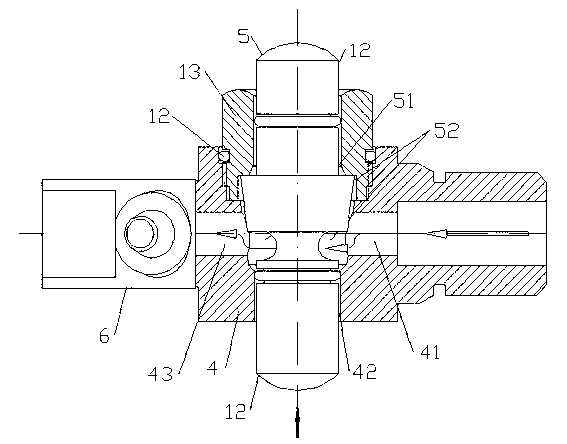

[0014] The present invention will be further described below with reference to the accompanying drawings.

[0015] An air valve mechanism of a carbon arc gouging gun, which has a pressure rod type manual air valve composed of a valve housing 4, a valve cover 13 and a valve core rod 5, and the valve housing 4 is provided with a valve core penetrating through both ends Cavity 42, one end of spool cavity 42 is connected with hollow type bonnet 13 by screw thread, and the middle part of spool cavity is truncated cone shape, is respectively provided with air inlet 41 and on the valve casing of truncated cone shape cavity both sides. The air outlet 43, the air inlet 41 and the air outlet 43 are respectively connected to the air inlet connecting pipe 3 and the air outlet connecting pipe 6, and the air inlet connecting pipe 3 is connected to the external air source pipe 11 and the power lead 10. The valve housing 4 of this embodiment is integrally formed with the air inlet connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com