Sensor shell processing method

A technology of a sensor housing and a processing method is applied in the processing field of the sensor housing to achieve the effects of ensuring the spatial position, reducing the cost of fixture manufacturing, and reducing the fitting clearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

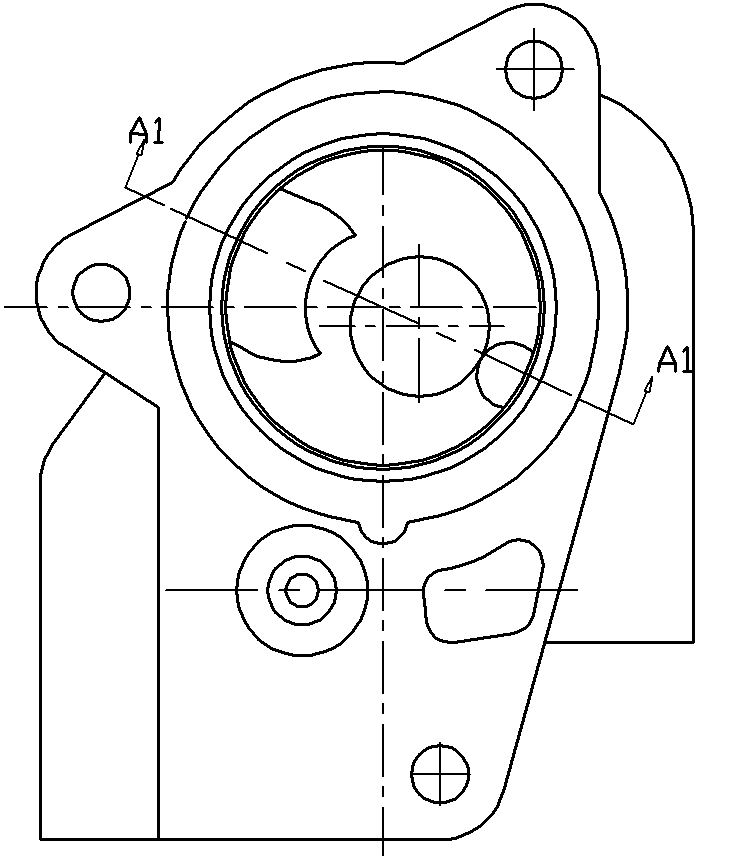

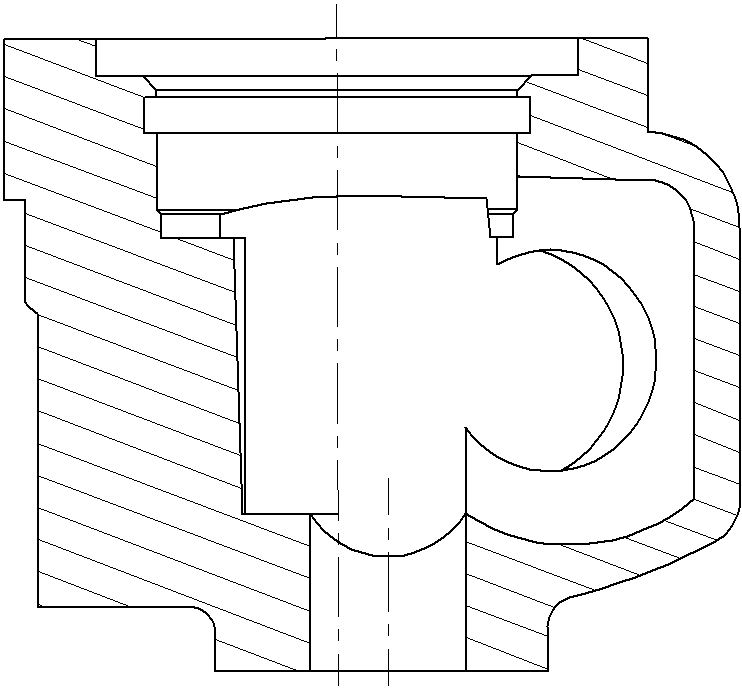

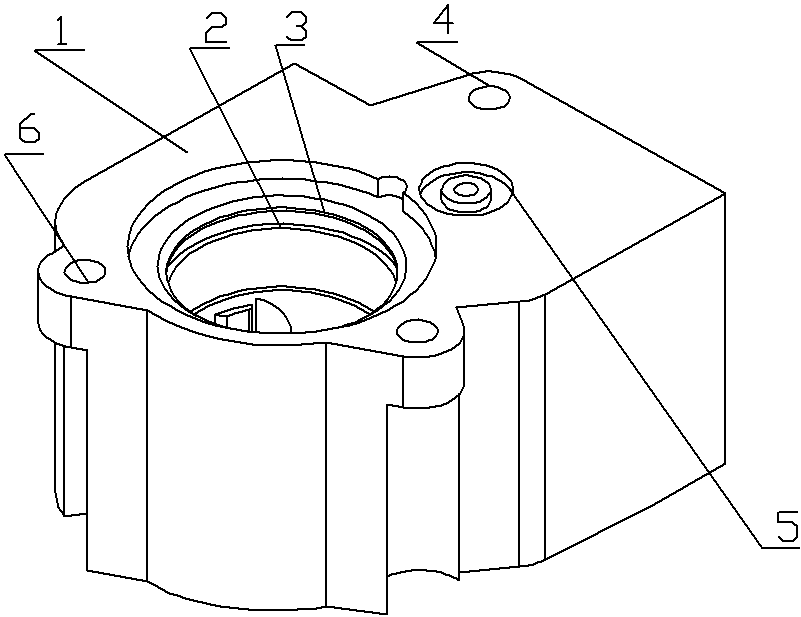

[0027] figure 1 , 2 and 3 represent the complicated structure of the sensor housing of the present invention, and the specific steps of a processing method of the sensor housing of the present invention are as follows.

[0028] The first step: grinding the reference plane on the blank;

[0029] Step 2: Milling the large plane 1, establishing the machining datum plane, drilling and milling positioning hole A4, positioning hole B6 and marking the relative positions of positioning hole A4 and positioning hole B6, such as Figure 4 shown;

[0030] Step 3: Milling the large plane 1, establishing the machining reference plane, drilling, milling the positioning hole A4 and positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com