Electrohydraulic hybrid driving system for seedling planting machine

An electro-hydraulic hybrid and drive system technology, applied in transplanting machinery, planting methods, agriculture, etc., can solve the problems of restricting multi-functional development, complex transmission mechanism, high maintenance cost, etc., and achieve high maintenance cost, low failure rate, The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

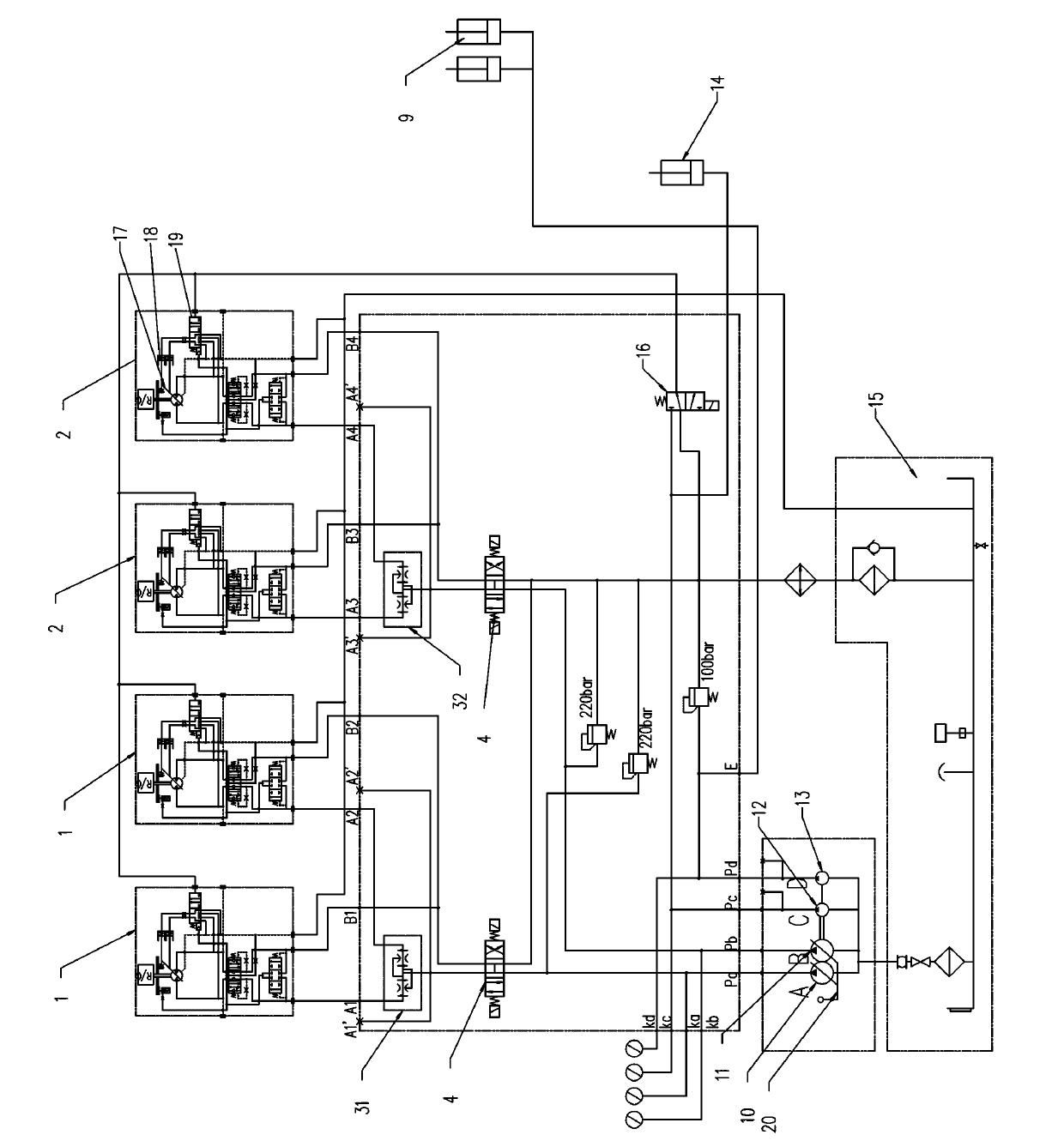

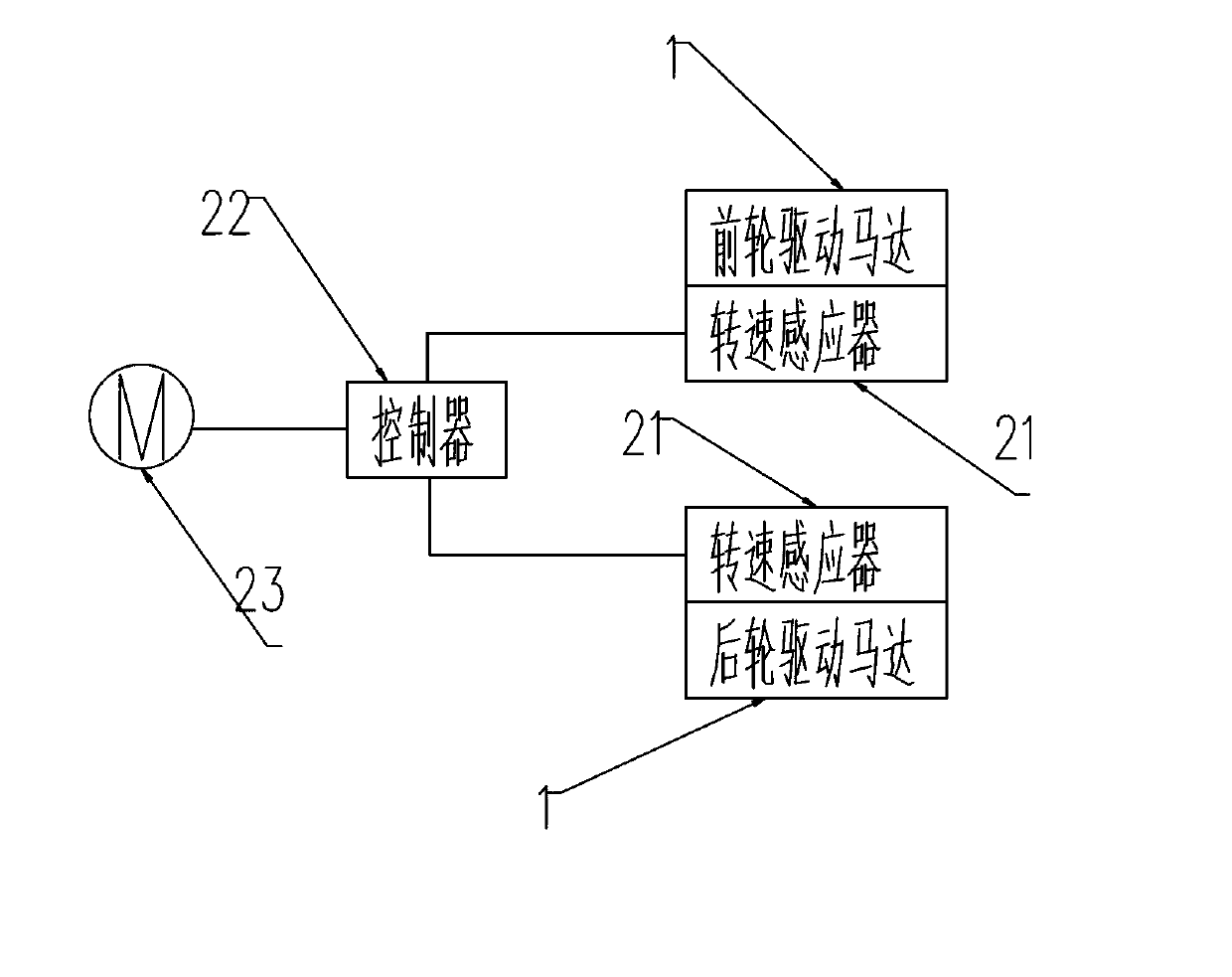

[0019] Such as figure 1 , figure 2 As shown, an electro-hydraulic hybrid drive system of a rice transplanter, which consists of a front wheel drive oil circuit, a rear wheel drive oil circuit, a planting part lifting oil circuit, a steering oil circuit, a rice transplanting motor and a controller, the front wheel The drive oil circuit is connected with two front wheel drive motors 1, and a front wheel synchronous valve 31 is arranged between the two front wheel drive motors 1, and the rear wheel drive oil circuit is connected with two rear wheel drive motors 2, and the two A rear synchronous valve 32 is provided between the rear wheel drive motors 2 . The front wheel drive oil circuit includes a front drive pump 10 and a reversing valve 4, the oil inlet of the reversing valve 4 is connected with the front drive pump 10, and one of the two working oil ports is connected with the two front wheel drive motors 1 The other is connected with the two front wheel drive motors 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com