Hydraulic pressure system of rice transplanter with stepless adjustment of planting distance

A hydraulic system and technology of a rice transplanter, applied in the field of rice transplanters, can solve the problems of complex transmission mechanism of the rice transplanter, restricting the development of multi-functionality, and high maintenance cost, and achieve the effects of simple structure, high maintenance cost and low maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

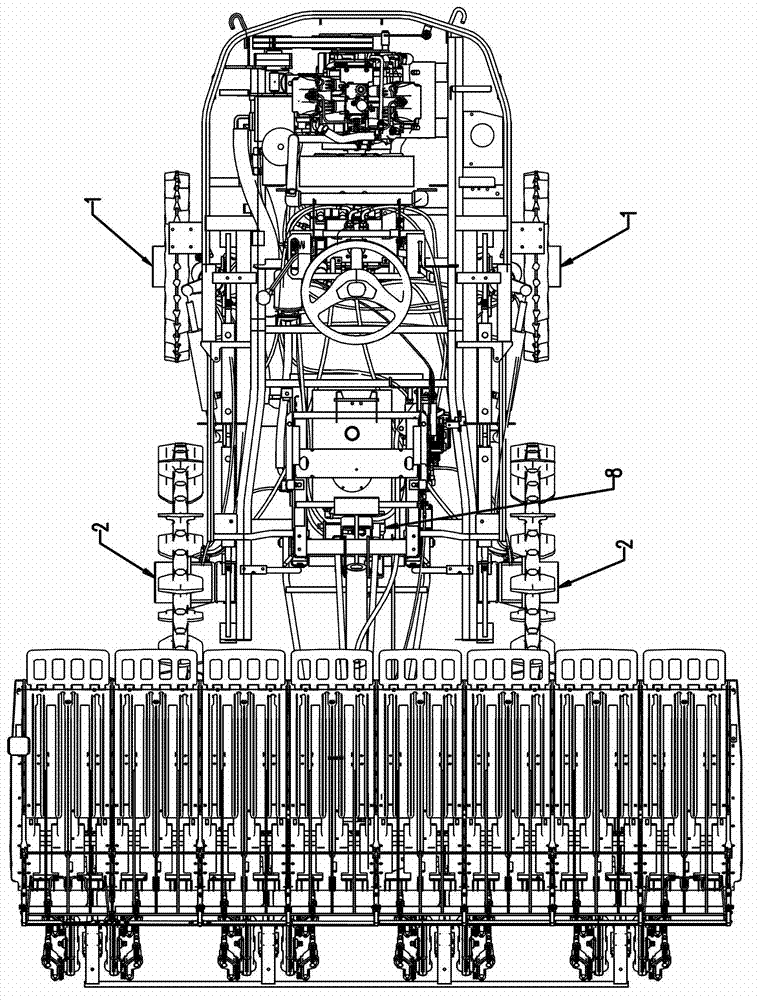

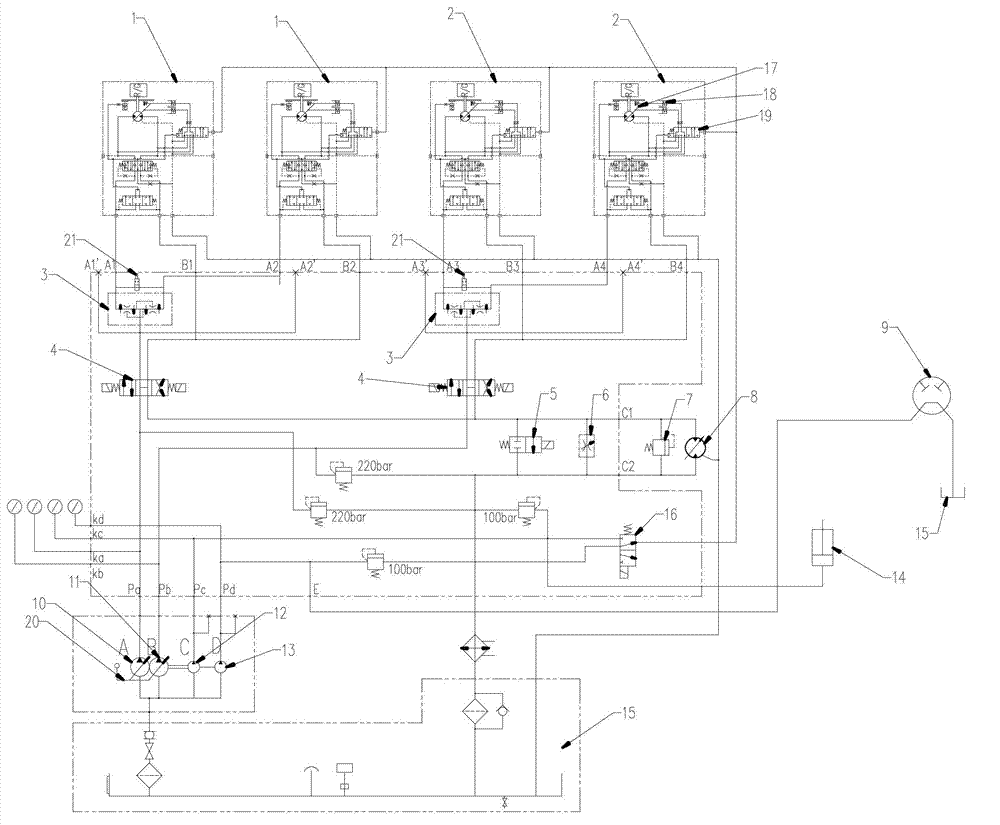

[0022] Such as figure 1 , 2As shown, the present invention is a hydraulic system of a rice transplanter with stepless adjustment of plant spacing, including an oil tank 15, an oil pump, and several electromagnetic valves, which include a front wheel drive oil circuit, a rear wheel drive oil circuit, a planting oil circuit, and a lifting oil for the planting portion. Road and steering oil circuit, the front wheel drive oil circuit is connected with two front wheel drive motors 1, a synchronous valve 3 is arranged between the two front wheel drive motors 1, between the two output ends of the synchronous valve It is connected through an on-off valve; the rear wheel drive oil circuit is connected with two rear wheel drive motors 2, and a synchronous valve 3 is also arranged between the two rear wheel drive motors 2, between the two output ends of the synchronous valve They are also connected through an on-off valve 21, and the control signal input end of the control circuit of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com