Open type belt conveying fall point unpowered dust removal system

A technology of belt transportation and dust removal system, applied in transportation and packaging, conveyor objects, cleaning devices, etc., can solve the problems of high energy consumption, complex system structure, inconvenient use and installation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

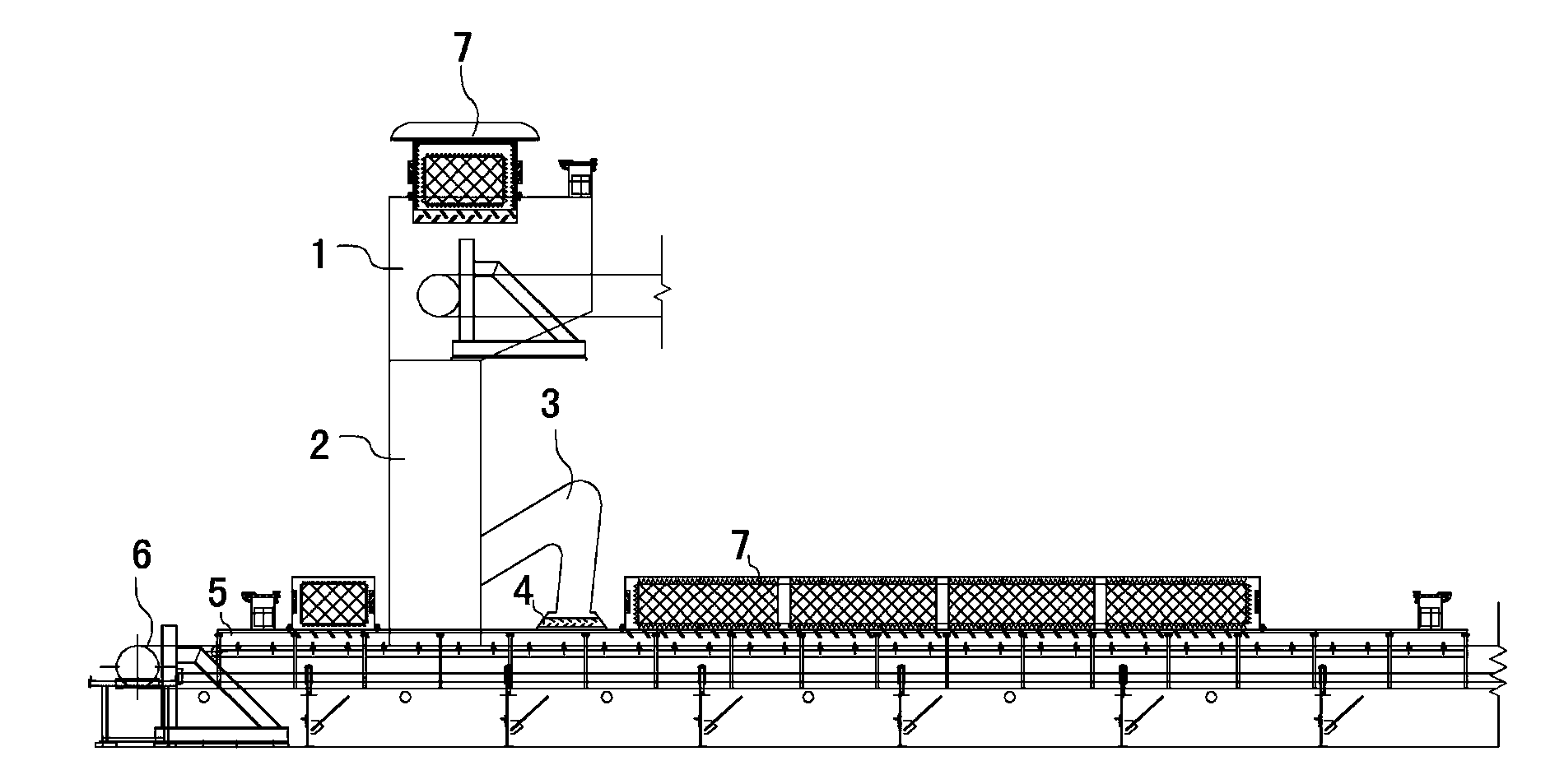

[0019] As shown in the figure, the open belt transportation drop point has no power dust removal system, which includes the machine head 1, the material flow tank 2 fixedly connected with the machine head 1, the dust air flow return pipe 3, the dust collection cover 4 and the belt sealing cover 5 The inlet of the dust air return pipe 3 communicates with the outlet of the dust collection cover 4; the outlet of the dust air return pipe 3 communicates with the inner cavity of the material flow tank 2; the belt sealing cover 5 is located on the top of the belt 6; The material outlet of the material chute 2 communicates with the belt sealing cover 5; the lower dust collection port of the dust collecting cover 4 communicates with the belt sealing cover 5; an open dust collector is fixedly arranged on the top of the machine head 1 7.

[0020] In the present invention, an open dust collector 7 is fixedly arranged on the top of the belt sealing cover 5 .

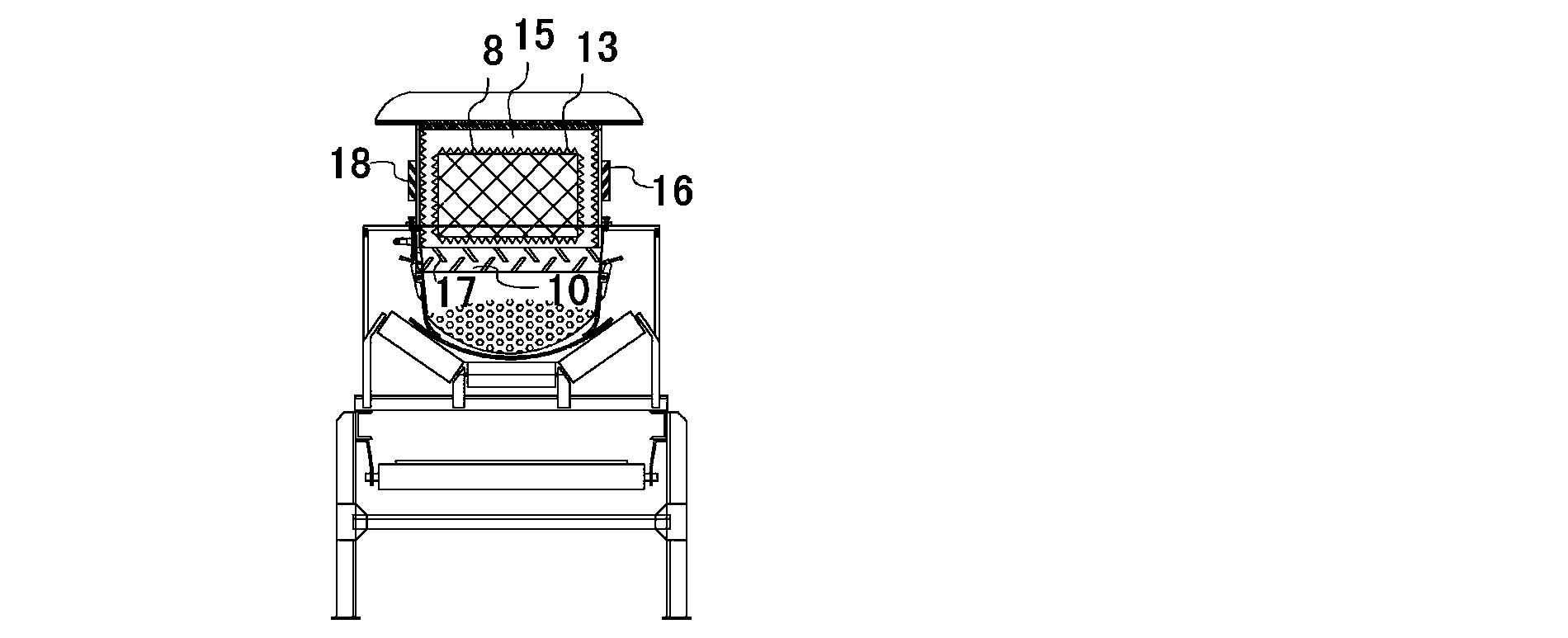

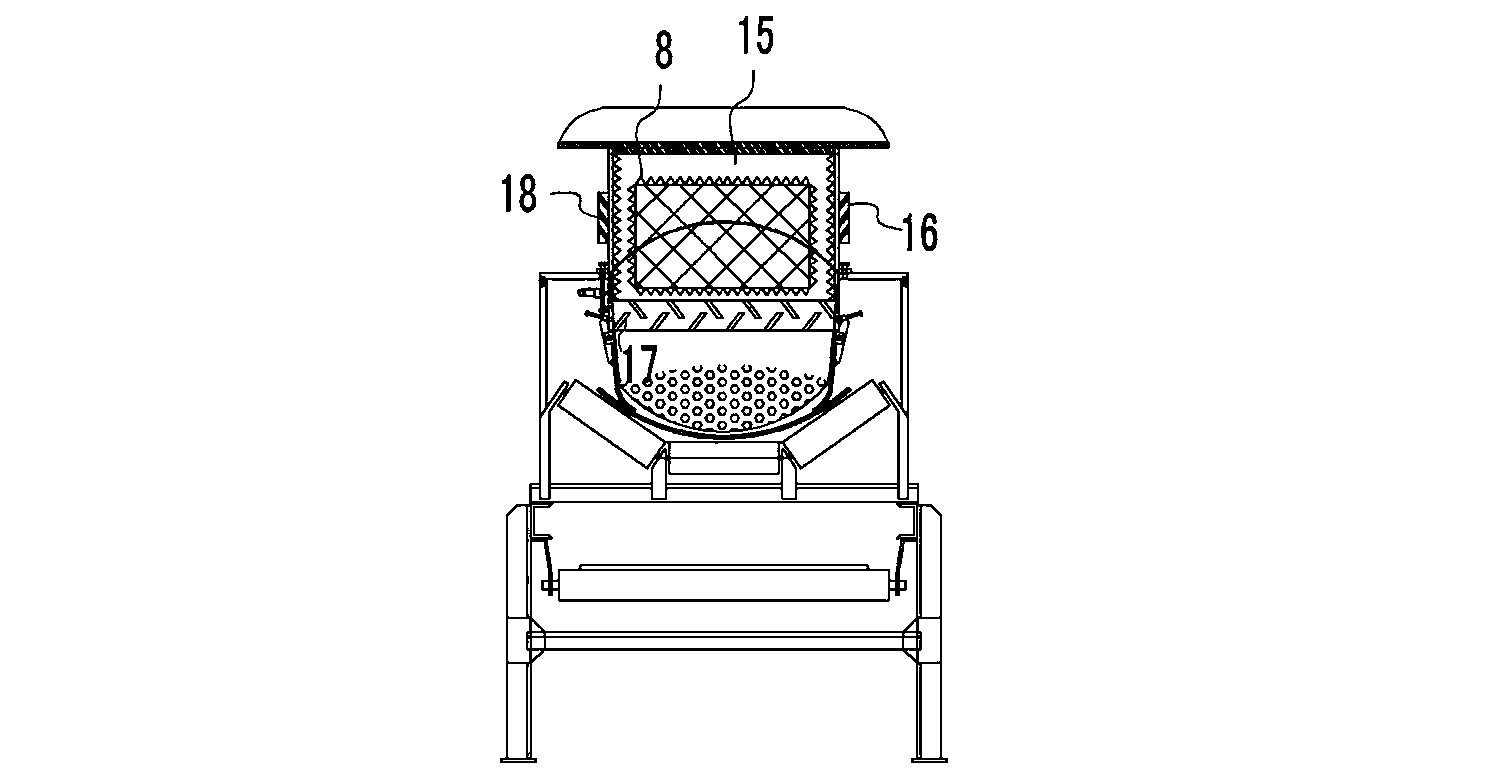

[0021] The open dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com