Foam glass production system

A foam glass and production system technology, applied in the field of foam glass production, can solve the problems of inability to meet the new production process, outdated production equipment, structural overload, etc., and achieve excellent impurity removal effect, high work efficiency, and high grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

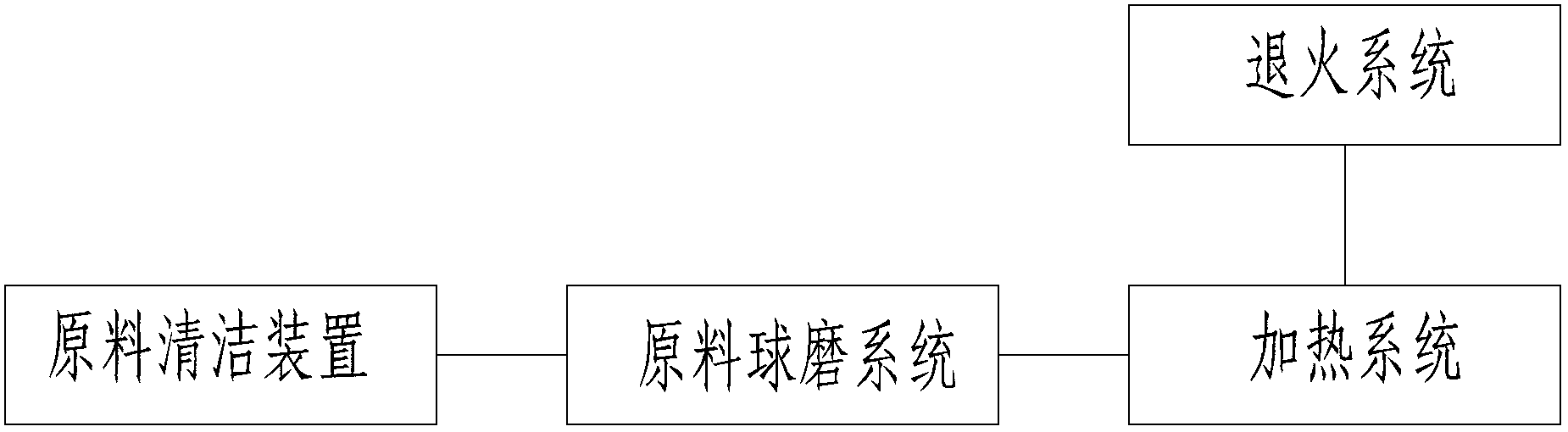

[0056] Such as figure 1 As shown, a foam glass production system includes a raw material cleaning system, a raw material ball milling system, a heating system and an annealing system for sequentially processing raw materials.

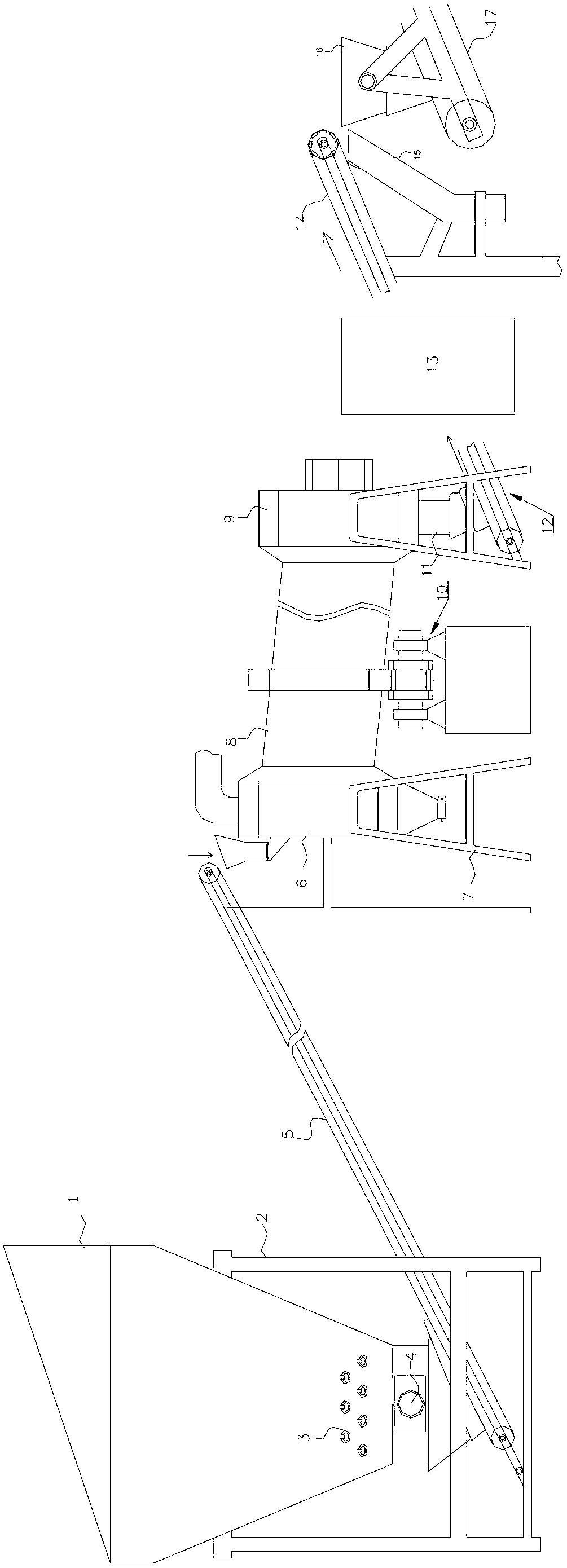

[0057] Such as figure 2 Shown is a schematic structural view of the raw material cleaning system of the present invention, including a feeding device, a drying and dust removal device, a hammer crusher, a magnetic impurity removal device and a storage bin connected in sequence.

[0058] The feeding device includes: a bracket 2, a feeding hopper 1 erected on the bracket 2, a rotating shaft 4 installed in the middle of the bottom of the feeding hopper 1, a turning motor that drives the rotating shaft (not shown in the figure), and the rotating shaft 4 is plugged with A plurality of rake teeth are used to turn over and stir the materials in the feed hopper 1. In this embodiment, there are three groups of rake teeth, each group of rake teeth is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com