Tea leaf comprehensive utilizing and deep processing method

A technology for deep processing and tea, which is applied in the field of comprehensive utilization and deep processing of tea. It can solve the problems of late start, backward deep processing technology, and the failure of natural tea extracts to meet environmental protection and hygiene quality and safety requirements, so as to achieve environmental protection, sanitation, quality and safety, and improve comprehensive utilization. benefit, increase the effect of product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

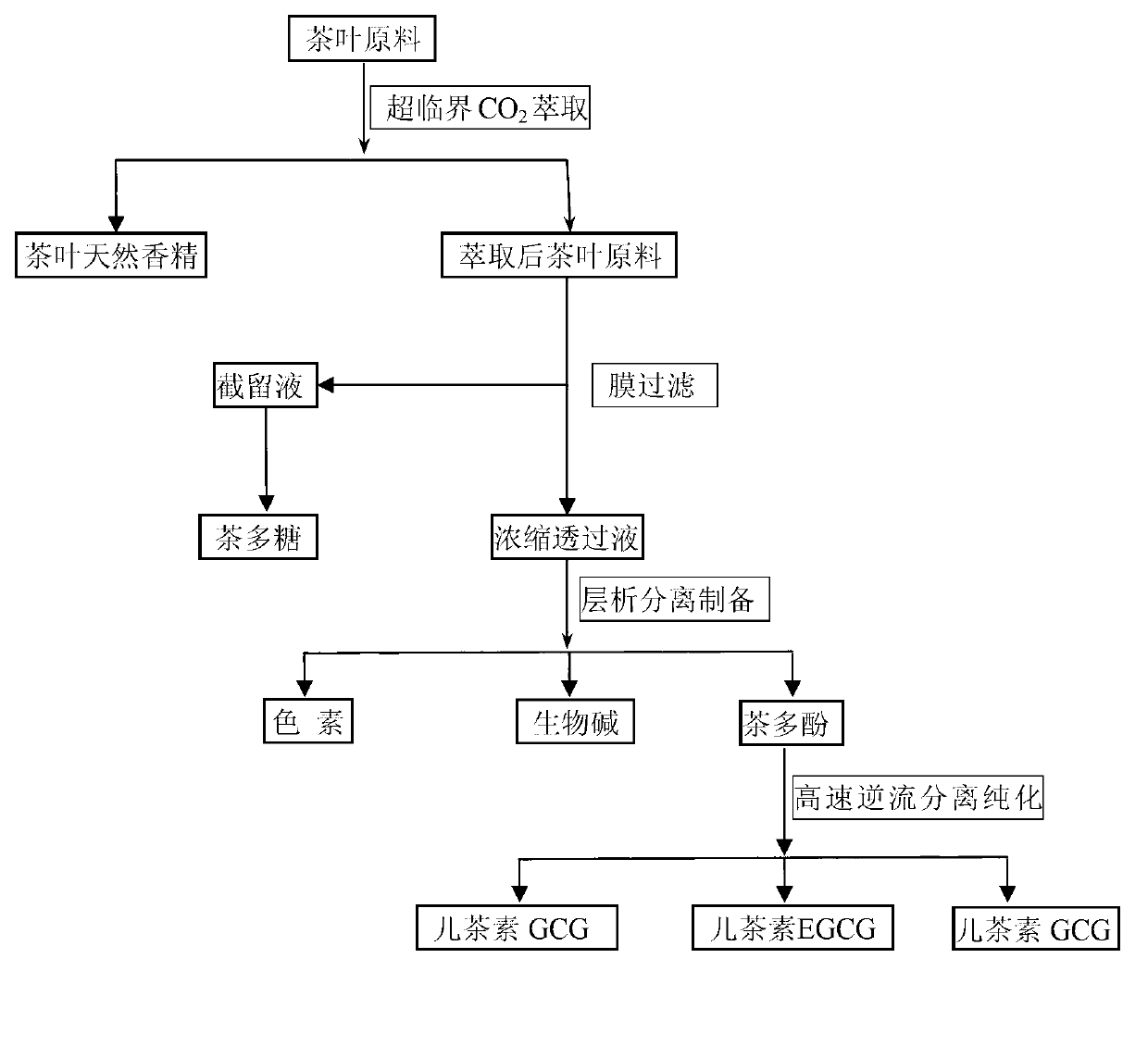

[0038] Embodiment 1 adopts the method of the present invention to tealeaves comprehensive utilization deep processing

[0039] (1) Supercritical CO 2 Extraction: loading 80g / L, extraction pressure 5000psi, extraction temperature 45°C, extraction 3 times, each extraction time 40min, separation temperature 75°C, separate and collect to obtain the natural tea essence;

[0040] (2) Membrane filtration: through supercritical CO 2 Extracted raw materials are leached with boiling water, coarsely filtered to remove tea dregs, the filtrate is filtered through a membrane, the membrane pore size is MWCO30000, the operating pressure is 0.3MPa, the temperature is 40°C, and the intercepted liquid is concentrated and dried to obtain tea polysaccharide;

[0041] (3) Column chromatography: the membrane filtration permeate is concentrated and then loaded onto the chromatography column. The filler is Cross-linkedagaroseanddextran. The flow rate of the eluent is 1BV / h. Alkaloids; then reverse elu...

Embodiment 2

[0044] Embodiment 2 adopts the method of the present invention to tealeaves comprehensive utilization deep processing

[0045] (1) Supercritical CO 2 Extraction: loading 100g / L, extraction pressure 4500psi, extraction temperature 50°C, extraction 2 times, each extraction time 40min, separation temperature 70°C, separated and collected to obtain the natural tea essence;

[0046] (2) Membrane filtration: through supercritical CO 2 Extracted raw materials are leached with boiling water, coarsely filtered to remove tea dregs, the filtrate is filtered through a membrane, the membrane pore size is MWCO30000, the operating pressure is 0.4MPa, the temperature is 45°C, and the intercepted liquid is concentrated and dried to obtain tea polysaccharide;

[0047] (3) Column chromatography: The permeate from membrane filtration is concentrated and then loaded onto the chromatography column. SephadexLH-20 is used as the filler, and the flow rate of the eluent is 1BV / h. Alkaloids; then reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com