Preparation method of polyurethane resin for gravure composite ink

A technology of polyurethane resin and ink, which is applied in ink, application, and household appliances, etc., can solve the problems of low composite strength, poor adhesion, and poor color development, and achieve high composite strength, mild reaction, and strong polarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of polyurethane resin for gravure composite ink, specifically comprises the following steps:

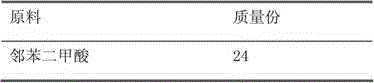

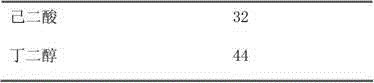

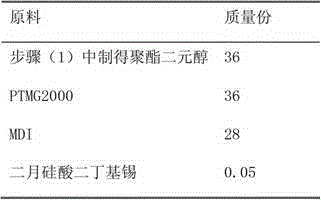

[0041] (1) Preparation of polyester polyol

[0042]

[0043]

[0044] Add 24 parts by mass of phthalic acid, 32 parts by mass of adipic acid, and 44 parts by mass of butanediol into the polyester synthesis kettle, raise the temperature to 200-240°C, and react for 5 hours until the acid value is less than 20. Esterification reaction: After the esterification reaction is completed, the temperature is lowered to 160°C, the vacuum pump is started, and the vacuum is kept at -0.094Mpa for 2 hours. After that, the vacuum degree is kept constant, and the temperature of the kettle is slowly raised for 5 hours to 210°C, after the total amount of the distillate reaches the theoretical value of 15 parts by mass, the distillate is released to obtain a polyester diol with an acid value of 0.6 and a hydroxyl value of 55;

[...

Embodiment 2

[0052] The present embodiment provides a kind of preparation method of polyurethane resin for gravure composite ink, specifically comprises the following steps:

[0053] (1) Preparation of polyester polyol

[0054]

[0055] Add 27 parts by mass of isophthalic acid, 23 parts by mass of adipic acid, and 50 parts by mass of neopentyl glycol into the polyester synthesis kettle, heat up to 200-240°C, and react for 5 hours to complete the esterification reaction; esterification After the reaction is completed, the temperature is lowered to 160°C, the vacuum pump is started, and the vacuum is kept at -0.094Mpa for 2 hours. After that, the vacuum is kept constant, and the temperature of the kettle is slowly raised to 210°C in 5 hours. After amounting to 20 parts by mass, emit a distillate to obtain a polyester polyol with an acid value of 0.3 and a hydroxyl value of 57;

[0056] (2) Preparation of NCO-terminated prepolymers:

[0057]

[0058] After mixing 56 parts by mass of p...

Embodiment 3

[0063] The present embodiment provides a kind of preparation method of polyurethane resin for gravure composite ink, specifically comprises the following steps:

[0064] (1) Preparation of polyester polyol

[0065]

[0066] Add 48 parts by mass of adipic acid and 52 parts by mass of diethylene glycol into the polyester synthesis kettle, raise the temperature to 200-240°C, and react for 5.5 hours to complete the esterification reaction; after the esterification reaction is completed, cool down to 160°C , start the vacuum pump, carry out vacuuming, keep the vacuum degree at -0.094Mpa, pump for 2 hours, after that, keep the vacuum degree constant, slowly increase the temperature of the kettle to 210°C in 5 hours, and after the total fraction reaches 25 parts by mass, Emit the distillate to obtain a polyester diol acid value of 0.9 and a hydroxyl value of 54;

[0067] (2) Preparation of NCO-terminated prepolymers:

[0068]

[0069] After mixing 76 parts by mass of polyeste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com